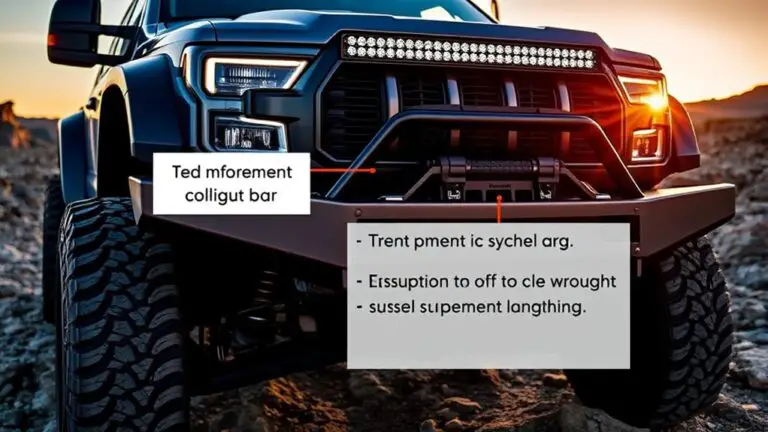

How to Source the Right LED Light Bars to Minimize Wheel Fitment Rubbing on a Tow Rig

To source the right LED light bars and minimize wheel rub on a tow rig, start with precise bar size selection that fits your bumper and fender geometry, then opt for low-profile mounting and adjustable brackets that preserve suspension travel. Align bar length to avoid tire contact at full steering and use rigid, corrosion‑resistant mounts….