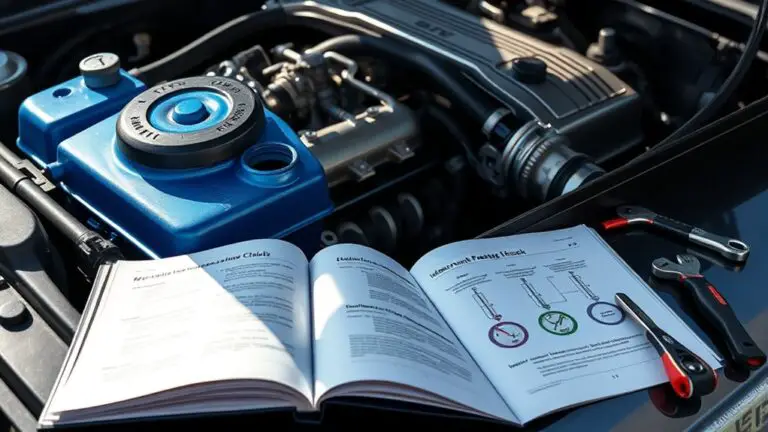

How Climate Affects Scale Build-Up and Maintenance Tips

Temperature and rainfall drive scale formation, so track highs, humidity swings, and precipitation to time targeted, eco-friendly maintenance. Higher temps boost mineral solubility and faster crystal growth, while humidity fuels biofouling on exposed surfaces. Rainy periods raise deposition rates; dry spells can sharpen buildup in confined spots. Align inspections and treatments with seasonal climate shifts,…