How to Perform a Coolant Flush and Why It Stops Overheating on Idle

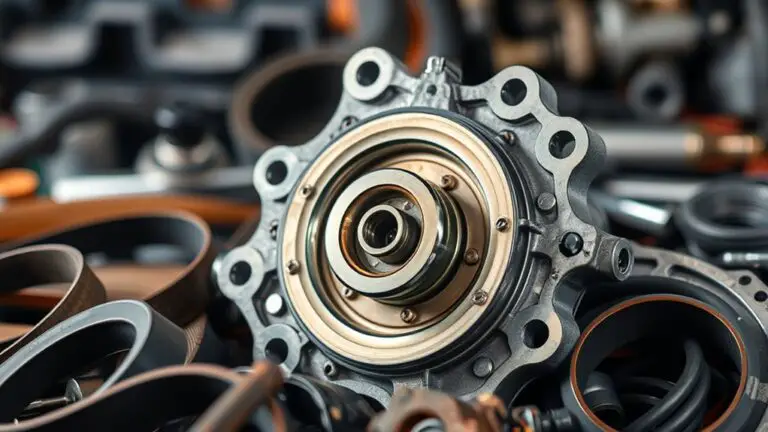

A coolant flush cleans sludge, rust, and mineral scale from your cooling system, restoring flow and heat transfer so it won’t boil or overheat at idle. Start by letting the engine cool, collect old coolant, and drain the radiator and hoses. Rinse with water or a flush solution, then refill with the correct mix and…