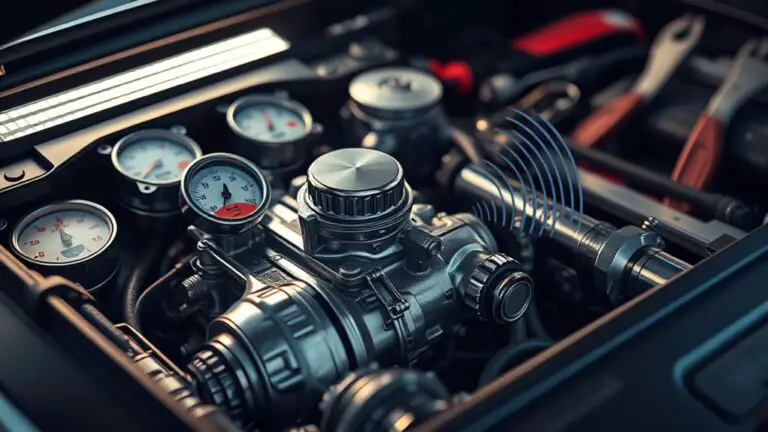

When a Bad Fuel Rail Ruins Fuel Economy and What to Do

A bad fuel rail disrupts pressure and injector spray, which wastes fuel and lowers economy. You’ll notice fluctuating rail pressure, misfires, hard starts, and odd engine response as symptoms. Start with quick checks: sniff for fuel leaks, inspect clamps and fittings, and verify the rail is clean and secure. If symptoms persist, diagnose rail pressure…