Common Wiring Faults That Cause Seat Belt Latch Failure in Safety Systems

Common wiring faults that cause seat belt latch failures include corrosion and damaged connectors, which raise resistance and degrade signal integrity; frayed or broken insulation that exposes conductors to moisture and contamination; faulty grounding or degraded back-to-charge paths that disrupt reference and timing; inconsistent resistance in sensing circuits that broadens tolerances and spurs intermittent readings; and moisture ingress or contamination that bridges contacts and alters insulation. Each issue undermines latch reliability, and further details can help you address them effectively.

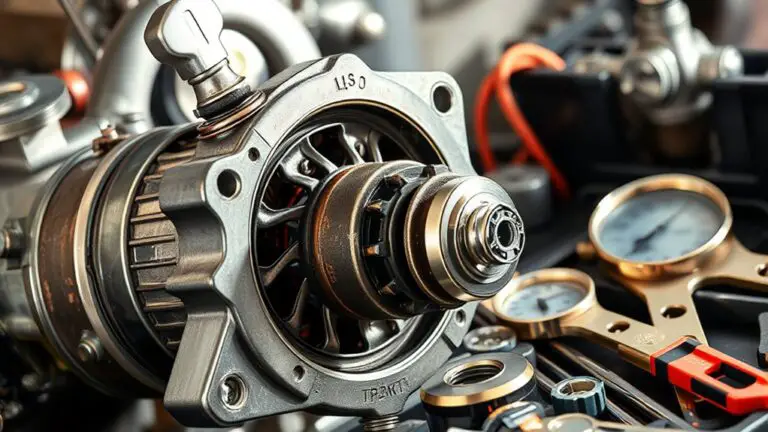

Corrosion and Damaged Connectors

Corrosion and damaged connectors threaten seat belt reliability by increasing resistance, degrading signal integrity, and risking premature system failure. You’ll assess contact surfaces, verify material compatibility, and document environmental exposure to prevent hidden faults. Evidence shows that microscopic corrosion layers elevate contact resistance, impairing data and power transfer essential to latch verification. Start with a visual inspection for discoloration, oxidation, or creep in connector housings, pins, and seals. If you see corrosion, apply approved corrosion prevention measures and replace compromised components; never reuse degraded parts. For connector maintenance, follow established torque specs, seating procedures, and locking mechanisms to guarantee consistent contact pressure. Maintain clean terminals using non-abrasive methods, and protect against moisture ingress with proper seals and gaskets. Implement a routine that tracks connector aging, exposure history, and maintenance intervals to reduce intermittent faults. Your disciplined approach enhances reliability, supports safe operation, and upholds system integrity through proactive corrosion prevention.

Frayed or Broken Wiring Insulation

Frayed or broken wiring insulation compromises both mechanical integrity and electrical safety by exposing conductors to moisture, abrasion, and contamination. You should inspect insulation along loom pathways, near connectors, and at flex joints for cracks, tears, or discoloration. Evidence-based maintenance shows that early detection prevents short circuits and latch misalignment caused by intermittent grounding or power loss. Start with a systematic visual audit, complemented by gentle tactile checks to locate hairline frays hidden under protective jackets. When you find damaged insulation, classify the material type—PVC, polyurethane, silicone—and assess its aging indicators, such as cracking or hardening. Apply wiring maintenance tips: replace compromised sections, reroute away from moving parts, and secure with appropriate clips to reduce flex fatigue. Use compatible insulation materials rated for automotive use, and verify that insulation thickness and abrasion resistance meet OEM specifications. Document findings, schedule proactive replacement, and re-test latch operation to guarantee reliable safety performance.

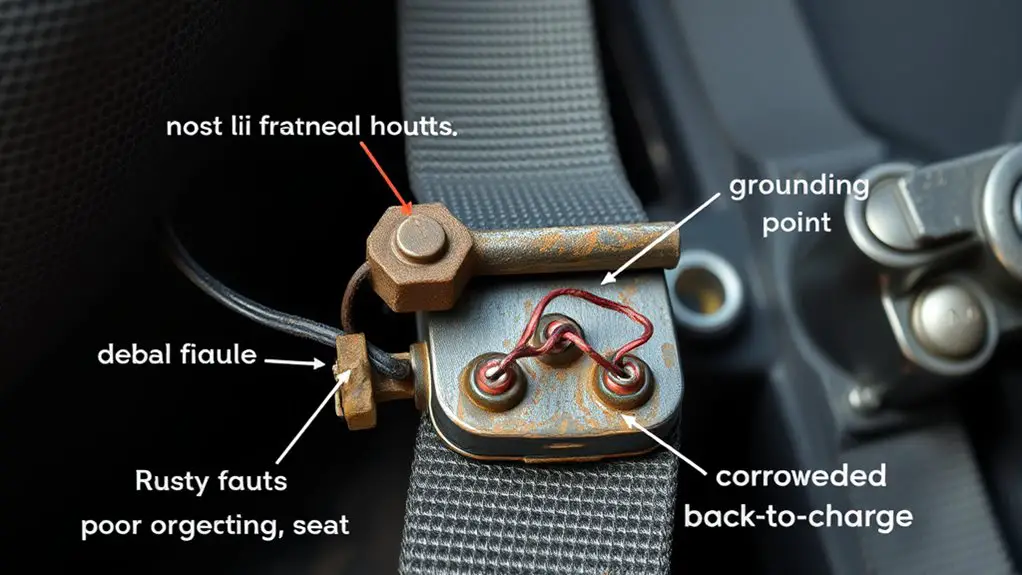

Faulty Grounding and Back-to-Charge Paths

Faulty grounding and back-to-charge paths can cause intermittent power loss, latch misalignment, or unintended deployment if return currents aren’t properly routed. You need to appreciate how grounding techniques and charge pathways shape current flow, noise rejection, and trigger reliability in safety systems.

1) Identify improper chassis versus signal ground bonds, and correct with low-impedance connections to reduce potential differences that drive creeping currents.

2) Inspect return paths for corrosion, loose ferrules, or damaged solder joints that elevate impedance and create voltage offsets under load.

3) Verify that charge pathways are uninterrupted, using shielded conductors where high-speed signals coexist with power, preventing cross-talk and timing errors.

4) Implement grounding strategies that maintain a consistent reference across modules, and document any intentional ground separations to avoid hidden loops and adverse transient responses.

Inconsistent Resistance in Sensing Circuits

In sensing circuits, resistance can vary unexpectedly due to temperature effects, aging components, or poor contact interfaces, and these fluctuations can degrade accuracy and trigger reliability. You’ll see how small resistance shifts propagate through a measurement path, altering voltage references, bias currents, and interpreted states. In practice, resistance fluctuations can cause drift in sensed signals, leading to false positives or missed detections of seat belt latch status. You should look for telltale signs: broadened tolerances, intermittent readings, or inconsistent latch reports across similar conditions. Quantify impact by comparing baseline values with excursions under normal operation, and map how these changes affect trip thresholds. Implement robust practices: use low-temperature-coefficient resistors, secure connections, and periodic calibration checks. Prioritize redundancy and diagnostic checks that distinguish sensing circuit failures from transient noise. By embracing rigorous testing, you reduce uncertainty and strengthen system reliability without sacrificing operational freedom.

Moisture Ingress and Contamination Effects

Moisture ingress and contamination can compromise seat belt system reliability by altering electrical insulation, corroding contact surfaces, and promoting conductive path formation; even trace amounts can bias sensor readings and trigger false reports. You must assess how moisture sealing and contamination sources interact with harnesses, connectors, and sensor modules to preserve integrity. Systematic evaluation shows that small amounts of liquid or vapor can change insulation resistance, shift voltage bias, and create leakage paths that mimic fault conditions.

Moisture and contamination degrade seat belt electronics, bias sensors, and forge false faults.

- Moisture sealing effectiveness: verify seals against ingress and verify enclosure integrity under temperature cycling.

- Contamination sources mapping: identify dust, oil, and environmental residues that can bridge contacts or skew diagnostics.

- Connector cleanliness and coatings: track corrosion potential, apply appropriate corrosion inhibitors, and ascertain proper mating force.

- Environmental exposure controls: implement ingress barriers, condensation management, and recommended protective housings for vulnerable routes.

Frequently Asked Questions

Can Environmental Vibration Cause Intermittent Latch Signals?

“Time is money,” you tell yourself, and yes—environmental factors can cause intermittent latch signals. You’ll find vibration effects loosen connectors, fatigue contacts, and shift harness positions, creating sporadic readings. Systematically you should monitor vibration spectra, tighten fasteners, and verify continuity under load. Environmentally induced impedance changes and EMI can mimic faults, so validate with controlled bench tests plus real-world vibration profiles. Consistent data logging confirms whether intermittent signals stem from environmental factors or genuine wiring faults.

Do Manufacturing Defects Lay Latent in Wiring Harnesses?

Yes, latent defects can lie in wiring harnesses, and you should insist on rigorous checks. You’ll find that manufacturing quality directly influences early failure risk, with latent defects surfacing only under stress or over time. You deserve transparent test records, traceable lot numbers, and consistent inspection criteria. Systematically verify continuity, insulation integrity, and connector reliability. Document findings, demand corrective actions, and uphold robust quality controls to minimize hidden faults and guarantee dependable safety performance.

How Do ECU Diagnostics Misinterpret Minor Wiring Faults?

ECU diagnostics can misinterpret minor wiring faults by overreacting to transient signals and subtle resistance changes. You’ll see faulty connections trigger false fault codes, while diagnostic limitations may mask gradual degradation as intermittent readings. You’ll want to test circuits with stable loads, document voltage profiles, and compare against baseline data. Rely on repeated measurements, not a single snapshot, and acknowledge that ECU logic may flag non-critical anomalies as faults, narrowing your real-world certainty.

Can Seat Belt Pretensioners Be Affected by Micro-Cracks?

Yes, seat belt pretensioners can be affected by micro-cracks. You should monitor pretensioner functionality through careful inspection, testing, and maintenance records. Micro crack identification is key, as these cracks may propagate and degrade activation. If a micro crack is found, replace components or perform recalibration to preserve pretensioner performance. Systematic diagnostics, backed by evidence, help you guarantee reliability and keep your safety system ready for deployment in emergencies.

Are There Non-Contact Methods to Test Wiring Integrity?

Non-contact methods do exist to test wiring integrity. You can use non-invasive testing like infrared thermography, inductive sensors, or high-frequency time-domain reflectometry to assess signal integrity without touching conductors. By scanning for hotspots, impedance changes, or reflections, you gain actionable evidence about circuit health. You’ll interpret results with a systematic, evidence-based mindset, ensuring the test preserves safety and reflects real operating conditions. This approach supports informed decisions and preserves your freedom to explore reliable diagnostics.