Common Wiring Issues That Mimic Malfunctioning Sensors

Common wiring issues can mimic sensor malfunctions, leading to misdiagnoses. Loose connections create intermittent signals, while frayed wires can cause short circuits. Corrosion at terminals increases resistance, complicating diagnostics further. It’s essential to check for these problems using a multimeter and visual inspection techniques. Regular maintenance can prevent these issues and guarantee reliable sensor performance. Understanding these factors is key to accurate troubleshooting in your vehicle’s electrical system. More insights await as you explore further.

Understanding Vehicle Sensor Functions

Understanding vehicle sensor functions is essential for diagnosing wiring issues effectively. Each sensor plays a critical role in your vehicle’s performance, providing data that influences everything from engine management to safety systems. When sensors aren’t calibrated properly, you risk receiving inaccurate signals, which can lead to faulty assumptions about the vehicle’s condition.

Signal interference is another important factor. External electromagnetic fields, physical obstructions, or even poor wiring can disrupt the signals transmitted between sensors and the vehicle’s control units. This noise can mimic sensor malfunctions, complicating your diagnostics.

To maintain freedom in your vehicle’s operation, you must guarantee that both sensor calibration and wiring integrity are prioritized. By understanding these functions, you can streamline troubleshooting processes and avoid unnecessary repairs, ultimately empowering you to take control of your vehicle’s health.

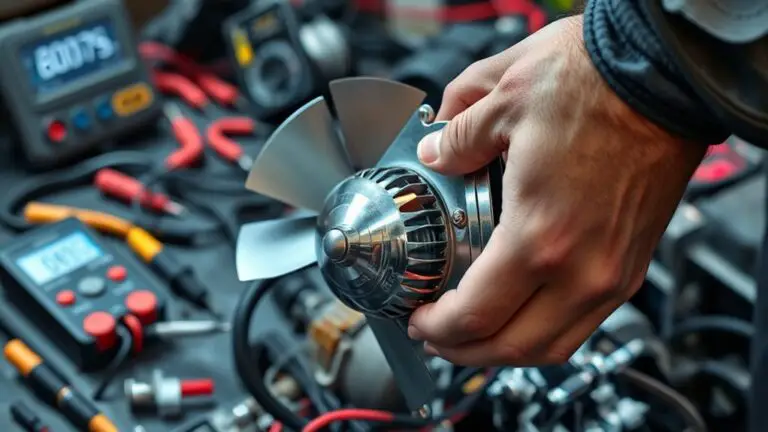

Common Wiring Problems Overview

When troubleshooting wiring issues, it’s essential to identify common problems such as loose connections, damaged insulation, and corroded terminals. These issues can lead to performance failures and safety hazards if not addressed promptly. Understanding these wiring faults will help you maintain the integrity of your vehicle’s electrical system.

Loose Connections

While loose connections may seem minor, they can lead to significant electrical issues if not addressed promptly. These weak points compromise connection stability, resulting in intermittent functionality or complete sensor failure. When troubleshooting, start by visually inspecting connections for signs of wear or corrosion. Gently wiggle wires to identify any loose spots; if movement occurs, it’s a clear indication that you need to secure those connections. Use appropriate tools to tighten terminals or replace connectors as necessary. Ignoring these loose connections can escalate into larger problems, including costly repairs. By employing diligent troubleshooting techniques, you can guarantee your system functions reliably, giving you the freedom to focus on what truly matters without the worry of unexpected electrical failures.

Damaged Insulation

Damaged insulation is one of the most common wiring problems you might encounter, and it can have serious implications for electrical safety and performance. Over time, insulation wear can lead to short circuits, shock hazards, or equipment failure. Recognizing the signs is vital for maintaining your system:

- Frayed or cracked insulation

- Discoloration or melting

- Exposed wires

- Frequent tripping of circuit breakers

- Burning smells near wires

If you notice any of these issues, immediate insulation repairs are essential. Ignoring damaged insulation can escalate minor problems into major safety concerns. Always prioritize your electrical safety by regularly inspecting your wiring and addressing any signs of wear before they become hazardous.

Corroded Terminals

Corroded terminals can lead to significant electrical issues, impacting both safety and performance. When terminals corrode, they create resistance, which can mimic sensor malfunctions. You might notice erratic behavior in your system, leading to frustration and unnecessary repairs. To address this, focus on corrosion prevention through proper sealing and ensuring good ventilation. Regular terminal cleaning is essential to maintain peak conductivity; use a suitable cleaner and a soft brush to remove buildup. Inspect connections frequently, as early detection can save you from costly replacements. By staying proactive with terminal maintenance, you can enhance reliability and extend the lifespan of your electrical systems, ensuring they perform efficiently without the interference of corrosion-related problems.

Faulty Connections: Causes and Symptoms

When connections within an electrical system become faulty, they can lead to a range of operational issues that compromise safety and functionality. Understanding the causes and symptoms of faulty connections is essential for maintaining system integrity.

- Faulty connectors can create intermittent signals, leading to erratic device behavior.

- Inconsistent power supply may result from loose or corroded connections.

- Overheating can occur due to poor contact, risking damage to components.

- Frequent disconnections might indicate underlying connection issues.

- Warning lights may illuminate unexpectedly, suggesting sensor malfunctions.

Recognizing these symptoms early can save you from more significant problems down the road. If you suspect faulty connections, investigate thoroughly. Checking connectors for wear, tightness, and corrosion will help guarantee peak performance. By addressing these issues promptly, you’ll maintain system reliability and enjoy peace of mind.

Frayed Wires: Detection and Impact

Frayed wires are a critical issue that can compromise safety and performance in electrical systems. You can identify them by inspecting insulation for visible damage or exposed conductors. Ignoring these problems may lead to short circuits, electrical fires, or equipment failure.

Identifying Frayed Wires

How can you effectively spot frayed wires before they lead to bigger problems? Conducting regular inspections is essential for ensuring wire maintenance. Here are some key indicators to look for:

- Visible wear or exposed copper strands

- Discoloration or burn marks on insulation

- Unusual heat during electrical testing

- Cracks or breaks in wire sheathing

- Frequent electrical malfunctions or shorts

Regularly checking these elements can help you identify frayed wires early on. Ignoring these signs can compromise your system’s safety and efficiency. By staying proactive with inspections and electrical testing, you’ll maintain peak performance and avoid costly repairs down the line. Remember, a little vigilance goes a long way in preserving your electrical integrity and freedom from malfunctions.

Consequences of Damage

Although you might not notice the immediate effects, the consequences of ignoring frayed wires can be severe. A damage assessment is vital; frayed wires can lead to short circuits, voltage drops, or even complete system failures. These issues not only compromise your equipment’s functionality but can also pose safety hazards, including fire risks. Implementing effective repair strategies is essential. You should consider both immediate fixes, like insulating the damaged area, and long-term solutions, such as replacing the affected wiring altogether. Ignoring these frayed connections might save time initially, but the potential for escalated damage and costly repairs down the line makes proactive maintenance a far smarter choice. Prioritize your wiring integrity for both safety and ideal performance.

Corrosion: The Silent Saboteur

Corrosion can silently undermine electrical systems, often going unnoticed until significant damage occurs. This deterioration can lead to sensor malfunctions, which can be mistaken for other issues. To prevent this, understanding corrosion and implementing effective strategies is crucial.

- Regularly inspect connections for signs of corrosion.

- Apply protective coatings to vulnerable components.

- Utilize corrosion-resistant materials where possible.

- Maintain ideal humidity levels in storage and operational areas.

- Schedule routine sensor maintenance to identify early warning signs.

Ignoring corrosion can compromise performance and safety. By prioritizing corrosion prevention and adhering to a solid sensor maintenance routine, you can extend the lifespan of your electrical systems. Stay proactive, and don’t let corrosion be the silent saboteur that disrupts your operations. The freedom to guarantee reliability and functionality lies in your hands.

Diagnosing Wiring Issues vs. Sensor Failures

Identifying wiring issues is often complicated by the presence of sensor failures, as both can exhibit similar symptoms in electrical systems. To effectively separate the two, you’ll need to engage in thorough wiring diagnostics. Start by checking for loose connections, frayed wires, or shorts that could affect signal transmission. Use a multimeter to measure voltage and continuity in the wiring harness, ensuring the power supply is stable.

Next, explore sensor troubleshooting. Verify if the sensor is receiving the proper voltage and check its resistance against manufacturer specifications. If the sensor is functioning correctly, but symptoms persist, it’s likely a wiring issue. This systematic approach helps pinpoint the root cause, ensuring you don’t get misled by overlapping symptoms. By understanding the nuances between wiring and sensor problems, you can maintain a clearer path to resolution, keeping your electrical systems operational and efficient.

Preventative Measures for Wiring Integrity

To guarantee wiring integrity, implementing preventative measures is essential for long-term reliability. Regular wiring maintenance can prevent issues that lead to sensor malfunctions. By adopting effective inspection techniques, you can detect potential problems before they escalate.

- Conduct routine visual inspections for wear and tear.

- Utilize thermal imaging to identify hotspots.

- Perform continuity tests to ascertain proper connections.

- Apply protective coatings or insulation to vulnerable areas.

- Document all maintenance activities for future reference.

Frequently Asked Questions

Can I Fix Wiring Issues Myself, or Should I Hire a Professional?

You can tackle DIY repairs if you have some electrical knowledge and the right tools. However, if you’re unsure, hiring professional help is advisable. Wiring issues can be complex and safety is paramount. A professional guarantees proper diagnosis and repair, potentially saving you from future headaches. Weigh your comfort level against the complexity of the issue; sometimes, investing in a pro can provide peace of mind and a long-lasting solution.

How Do Weather Conditions Affect Vehicle Wiring?

Weather conditions can greatly affect your vehicle’s wiring. Extreme temperatures, moisture, and road salt can lead to wiring damage, causing shorts or corrosion. Cold can make insulation brittle, while heat can degrade it, exposing wires to elements. Rain and snow can introduce moisture, leading to electrical failures. If you’re not vigilant about these weather effects, you might face unexpected issues. Regular inspections can help you maintain your vehicle’s wiring integrity and prevent costly repairs.

What Tools Are Needed for Wiring Inspection?

For wiring inspection, you’ll need a few essential tools. A multimeter is vital for testing voltage, continuity, and resistance, helping you diagnose issues accurately. Additionally, a good quality flashlight aids in visual inspection, allowing you to identify frayed wires or loose connections in tight spaces. Wire strippers and crimpers are also beneficial for making necessary repairs. With these tools, you can guarantee your vehicle’s wiring system is functioning at its best.

Are There Specific Vehicles More Prone to Wiring Issues?

Yes, certain vehicle models are more prone to wiring issues. Common culprits include older cars, particularly those from the 1990s and early 2000s, due to aging insulation and connectors. Additionally, vehicles with complex electronic systems, like luxury models, may experience wiring problems more frequently. If you own one of these models, regular inspections can help you catch potential issues before they escalate, ensuring your vehicle remains reliable and safe.

How Often Should I Check My Vehicle’s Wiring?

You should check your vehicle’s wiring at least twice a year. Regular inspections help catch potential issues early. Look for vehicle wiring signs like frayed wires, corrosion, or loose connections. When checking, follow wiring maintenance tips such as cleaning terminals and verifying secure connections. If you notice any irregularities, address them promptly to avoid more significant problems. Staying proactive keeps your vehicle in top shape and guarantees your freedom on the road.