Cost and Safety: When to Call Certified EV Technicians for Traction Motor Noise

If you hear traction-motor noises, don’t rush to DIY diagnosis. Start with a safety check: pull over if vibrations spike, and note if sounds change with RPM, torque, or speed. Small, normal hums can be expected, but persistent clunks, buzzing, or power loss warrant a certified EV technician. They’ll follow a structured inspection, use calibrated tools, and verify electrical and mechanical safety before any disassembly. Elsewhere, you’ll find cost guidance and safeguards for trusted, transparent service.

Recognizing Normal Traction Motor Noises in EVs

Normal traction motor noises are a predictable part of EV operation and don’t necessarily indicate a fault. You’ll notice certain sounds as you drive, and recognizing them helps you stay confident about your electric vehicle’s performance. Normal sounds include light whirring during acceleration, a steady hum at cruising speed, and occasional gentle clunks when shifting or engaging powertrain components. You may also hear a soft buzzing as you vary torque or if accessory loads shift. These effects arise from motor windings, bearing tolerances, and drivetrain gearing operating within design specs. If the vehicle remains smooth, accelerates cleanly, and doesn’t exhibit new tonal changes under identical conditions, you’re likely within normal parameters. Keep in mind that ambient temperature and battery state of charge can alter perceived noise. Use these observations to maintain awareness of your car’s behavior, and trust that many, if not most, electric vehicles produce predictable normal sounds during everyday operation.

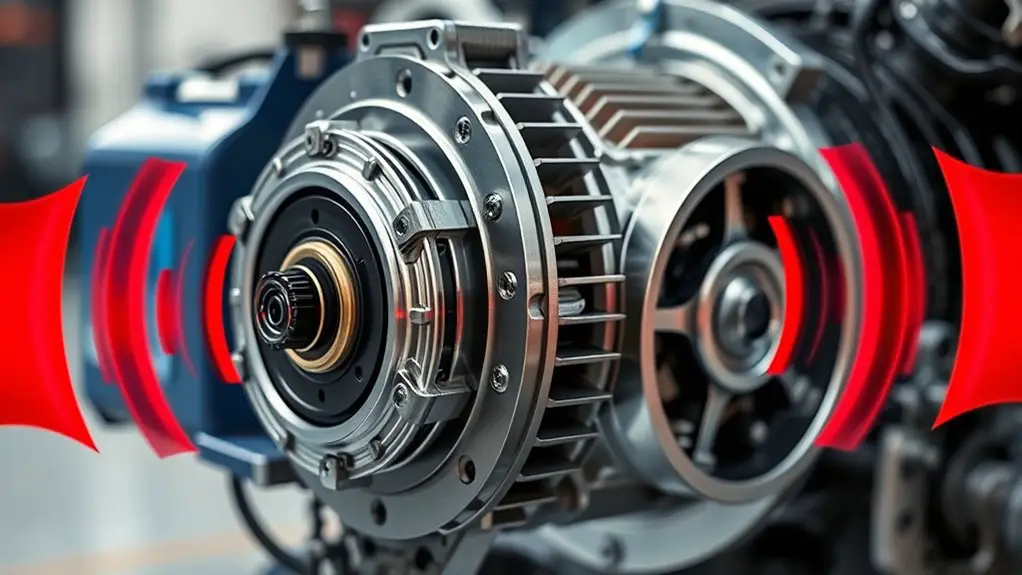

Red Flags That Require Immediate Technician Evaluation

Red flags aren’t subtle: they signal conditions that could indicate a safety or reliability issue and require prompt technician evaluation. When you notice unexpected sounds or performance issues, don’t delay testing or inspection. A sudden chuff, grinding, or rhythmic ticking could point to bearing wear, loose mounts, or degraded magnets. Persistent power loss, reduced acceleration, or abnormal pedal feel warrants expert diagnosis. If noises change with RPM or road speed, treat it as urgent. Any vibration you can feel through the chassis deserves professional confirmation. Safety systems integrity matters; vibration near the motor housing can foreshadow electrical or thermal faults. Document timing, locations, and conditions to speed evaluation.

| Symptom cue | Potential issue | Recommended action |

|---|---|---|

| Unexpected sounds | Bearing/mount wear | Schedule immediate inspection |

| Performance issues | Loss of power | Immediate diagnostic check |

| Vibration | Motor mounting, rotor imbalance | Ring alarm for technician visit |

| Noise variation with RPM | Mechanical or electrical fault | Prompt assessment |

| Sudden change | Acute fault onset | Do not drive; tow to service |

What Happens During a Certified EV Inspection

A certified EV inspection follows a structured, step-by-step process to verify motor health, electrical integrity, and safety-critical systems. You’ll be guided through a formal inspection checklist designed to guarantee consistent evaluation, not guesswork. The technician conducts a visual and operational review, confirming fasteners, wiring, connectors, and insulation meet specification. Next, battery and propulsion subsystems are tested for insulation resistance, voltage stability, and fault codes, with attention to thermal behavior under load. You’ll see the use of calibrated tools and standardized procedures to reproduce normal and fault conditions safely. Documentation is precise: findings are logged, measurements recorded, and any deviations flagged for remediation. Technician training is evident in the approach, making sure you understand what’s checked and why. The process ends with a clear summary and recommendations, enabling informed decisions about maintenance or repair. This inspection emphasizes safety, transparency, and reliable data, empowering you to act with confidence.

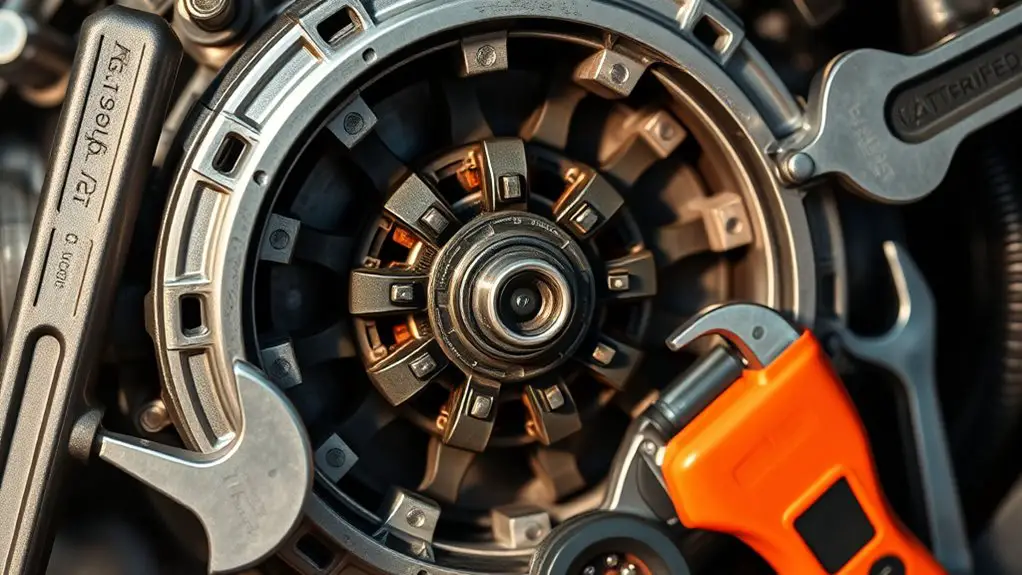

How Professionals Diagnose Traction Motor Issues Safely

Professionals diagnose traction motor issues safely by following a structured troubleshooting workflow that centers on safety, repeatability, and traceable data. You’ll use diagnostic tools to capture baseline electrical and mechanical signals, then compare against known-good profiles. Noise analysis guides early triage: is the sound mechanical, electrical, or a coupling issue? You document each step, ensuring actions are reversible and auditable.

- Isolate the suspect subsystem with controlled tests

- Record measurements with calibrated instruments

- Correlate acoustic cues with sensor data

- Log decisions and outcomes for traceability

You continuously verify safety—lockout-tagout, proper insulation, and PPE—before any disassembly. Procedures emphasize repeatable tests, so a second technician can reproduce results. Data-driven conclusions prevent guesswork, reducing risk to you and the vehicle. When uncertainties remain, you escalate with a clear, documented path rather than assumptions. This disciplined approach builds confidence in diagnosing traction motor issues and supports effective, responsible servicing.

Choosing the Right EV Technician: Credentials and Safeguards

Choosing the right EV technician means prioritizing credentials, safeguards, and a proven, verifiable track record. You should verify certification validity, industry recognition, and ongoing training. Certification importance isn’t optional; it signals formal criteria, safety standards, and current troubleshooting skills. Look for technicians who specialize in electric drivetrains or traction systems, with documented hands-on exposure to the exact motor styles in your vehicle. Request clear evidence of continuous education, not just a one-time credential. Safeguards matter: liability coverage, proper PPE, and adherence to NHTSA or regional EV service guidelines protect you and your equipment. Assess technician experience by reviewing case histories, repair outcomes, and client references. Favor transparent diagnostic methods, written estimates, and explicit scope limitations. A qualified technician should explain procedures, risks, and timelines in plain language. In the end, you gain freedom through informed choices, reduced downtime, and safer, more reliable traction motor maintenance.

Frequently Asked Questions

What Costs Are Typically Involved in an EV Traction Motor Inspection?

The typical costs include inspection pricing and technician fees, plus any diagnostic tests or parts if issues are found. You’ll usually see a base inspection price, my estimate varies by shop, and you may pay for extended diagnostics if the motor or controller needs deeper testing. Expect transparent pricing, ask for an itemized quote, and confirm what’s included—labor rate, shop fees, and any required parts or extensive measurements.

How Long Does a Certified Inspection Usually Take?

The inspection usually takes 1 to 3 hours, depending on findings and access. You’ll want an upfront ETA, so you know what to expect. During the session, the technician qualifications matter: certified EV specialists use standardized checks, tests, and documentation. You’ll have actionable results, not vague assurances. If components require deeper analysis, duration can extend, but you’ll receive a clear timeline before additional work begins. You’ll appreciate precise steps and trustworthy conclusions.

Can Noises Indicate Battery or Inverter Problems Too?

Yes, noises can signal battery health or inverter issues, not just traction motor problems. You should listen for grinding, whines, or rhythmic clicks alongside heat or reduced range. If you notice unusual sounds, test battery health and inspect the inverter for overheating, voltage dips, or error codes. Don’t ignore warning signs—consult a qualified technician to assess battery health, verify wiring, and diagnose inverter issues before they escalate. Stay proactive and safe.

Do Inspections Require EV Downtime or Vehicle Immobilization?

Inspections usually require some downtime and vehicle immobilization. You’ll park, power down, and isolate systems, while the technician runs tests. Expect a staged process: pre-checks, diagnostics, then remediation planning. EV maintenance timelines depend on technician availability, parts, and complexity. You’ll be kept informed, with clear milestones. Plan for interruptions, but you’ll get documented results. If you want minimal disruption, schedule when uptime is possible and verify contingency support.

Are There Insurance Implications for EV Traction Motor Repairs?

Yes, there are insurance implications for EV traction motor repairs. You should check your policy’s coverage scope, exclusions, and any deductible effects, plus how repair policies interface with manufacturer warranties. Verify whether towing, diagnostics, or replacement parts are covered, and whether aftermarket components affect your claim. Document all findings and get written confirmation from your insurer before proceeding, ensuring you understand limits, timelines, and any required certified technician repairs to maintain coverage.