Cost and Liability Considerations When Repairing Seat Occupancy Sensor

When repairing a seat occupancy sensor, you must weigh component cost, supplier reliability, and traceable documentation to protect safety and liability. Identify failure modes driving replacements, compare OEM vs. aftermarket parts, and verify warranties, lot codes, and supplier certifications. Budget labor hours and rates with task complexity, guarantee calibrated tools, and document every step for auditability. Separate diagnostic, replacement, and requalification activities, and secure chain-of-custody. If you continue, you’ll gain a clearer path to resilient, compliant repairs.

Assessing Component Costs for Seat Occupancy Sensor Repairs

When estimating component costs, you should start by identifying the specific seat occupancy sensor(s) involved and the failure mode driving repair needs. You assess part criticality, compatibility, and risk implications to determine a solid cost foundation. Focus on component sourcing options, noting OEM vs. aftermarket parts, warranties, and return policies. Compare sensor technology variants—pressure, weight, and capacitive types—to understand performance envelopes and failure indicators. Document expected lifecycles, failure rates, and potential rework or secondary parts, such as harnesses or connectors, that could influence pricing. Consider environmental factors like temperature, vibration, and EMI that affect survivability and long-term reliability. Guarantee traceability for safety audits by recording part numbers, lot codes, and supplier certifications. Translate these details into a defendable budget with contingencies for obsolescence or recalls. Your goal is a precise, defensible estimate that supports safe, compliant vehicle operation.

Labor Hours and Labor Rates: Impact on Repair Pricing

Labor hours directly influence repair pricing, as time estimates shape labor cost and scheduling accuracy. Labor rate variance matters because regional wages, technician skills, and demand affect what you’re billed for, even when the same task is performed. Consider how these factors interact with safety requirements, ensuring pricing remains transparent and tied to validated work content.

Labor Hours Impact

The number of labor hours and the associated rates directly shape repair pricing, since accurate estimates hinges on task complexity, technician skill, and required tooling. You’ll assess how each step, from diagnostic testing to component replacement, eats into time and budget. Labor efficiency matters: streamlined maneuvers, proper fixture use, and reduced rework cut total hours without compromising safety. You’ll factor in environmental constraints, access challenges, and the need for verified safety tests before concluding. Technician skill remains a core driver; experienced technicians complete tasks faster with fewer errors, lowering risk of misdiagnosis and warranty issues. Documented progress and clear timeboxes help prevent scope creep, enabling you to defend pricing with objective, repeatable measures. Precision in planning safeguards liability while preserving practical freedom in maintenance decisions.

Labor Rate Variance

While labor hours determine base cost, variances in labor rates can substantially alter total repair pricing, independent of time spent. You’ll encounter labor rate variance when technicians bill at different hourly prices due to experience, certifications, or regional demand. This shift affects the labor cost you pay, even if hours remain constant. Market fluctuations can widen or narrow these rates over short cycles, driving price unpredictability you must anticipate in budgeting and liability planning. When comparing estimates, inspect the rate structure, not just hours, and seek transparent line items for standard versus premium rates. Favor shops with documented rate policies, predictable invoicing, and consistency across similar tasks. Understanding rate variance helps you maintain safety standards without surrendering financial control or flexibility.

Pricing Considerations

Pricing is driven by both the hours worked and the rates charged, so you should evaluate both elements to understand total repair cost. Labor hours reflect task complexity, required tools, and diagnostic steps, while labor rates capture expertise, risk, and scheduling. You’ll want to benchmark expected timelines against actuals to identify inefficiencies, then align pricing with market trends and consumer expectations. Consider transparent quoting that itemizes hours and rate tiers, plus potential surge costs for hazardous environments or recalibration testing. This approach strengthens safety by linking effort to outcomes and avoids hidden charges. table:

| Task | Estimated Hours | Rate ($/hr) |

|---|---|---|

| Diagnosis | 1.5 | 120 |

| Recalibration | 2.0 | 130 |

| Validation | 1.0 | 110 |

| Contingencies | 0.5 | 125 |

| Total | 5.0 | – |

Tools, Equipment, and Specialization Requirements

You must have the right tooling and calibration methods to assess seat occupancy sensors accurately and safely. Specialized qualifications guarantee correct diagnosis, proper rework, and compliance with safety standards. Begin by outlining the exact tools, equipment, and credentials required to perform legitimate, liability-conscious repairs.

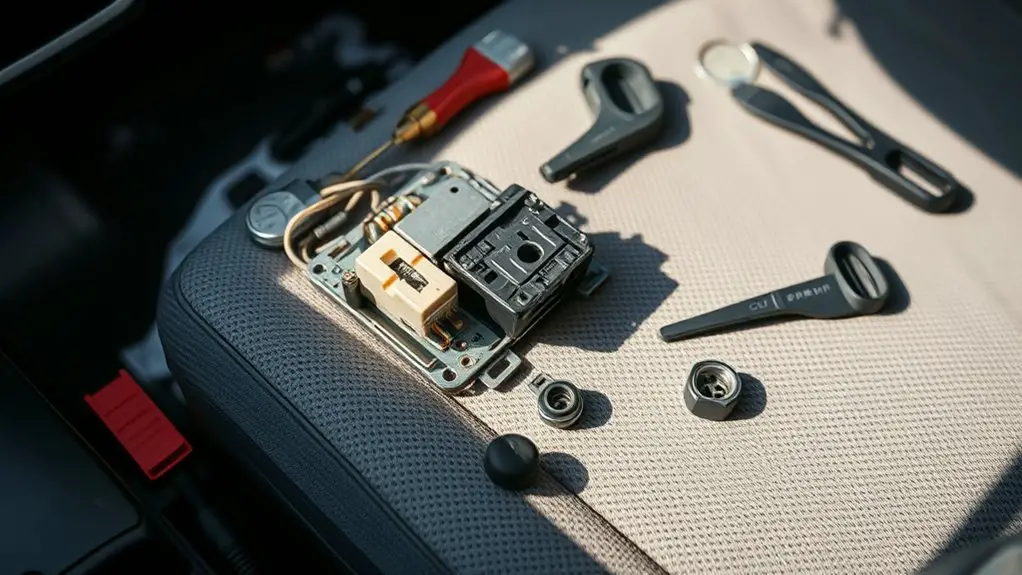

Tooling Requirements

Tooling requirements for seat occupancy sensor repair must be defined precisely to guarantee safety, accuracy, and repeatable results. You’ll tailor tooling types to the sensor’s topology, ensuring compatibility with diagnostic interfaces, fixture tolerances, and force limits. Equipment specifications should include calibrated measurement devices, torque control, and ESD-safe handling, paired with documented maintenance schedules. You’ll specify calibration intervals, traceability, and QA checkpoints to verify conformity after every procedure. Avoid improvisation that undermines repeatability; instead, deploy purpose-built fixtures and standardized connectors to minimize variability. Consider environmental controls, slipped tolerances, and material compatibility to prevent damage during disassembly and reassembly. Documentation should map tooling capabilities to repair steps, enabling traceable performance history while supporting liability mitigation and safety assurance.

Specialist Qualifications

Specialist qualifications for seat occupancy sensor repair require verified expertise in electronics safety, diagnostic methods, and mechanical handling; additionally, technicians must meet defined standards for tools, equipment, and area-specific specialization. You must demonstrate disciplined adherence to safety protocols, data integrity, and fault isolation accuracy before engaging in any repair activity. Specialist training encompasses hands-on procedures, risk assessments, and calibration techniques that align with vehicle manufacturer and regulatory expectations. Certification requirements should be clearly documented, including ongoing competency updates and observable performance metrics. You’ll need access to calibrated test apparatus, PPE, and secure work zones to prevent injury and cross-contamination of signals. By maintaining current credentials and practical proficiency, you guarantee liability mitigation, traceable workmanship, and reliable service outcomes for customers seeking freedom from uncertainty.

Compliance, Inspections, and Warranty Considerations

Compliance with applicable standards, inspections, and warranty terms is essential to verify reliable seat occupancy sensor performance and to minimize liability. You should map the relevant regulatory requirements for your region and vehicle type, then align repair steps to those expectations. Documented inspections serve as verifiable evidence of ongoing safety and function, reducing post‑repair disputes. Your process must clearly separate diagnostic testing, component replacement, and requalification to avoid ambiguity in accountability. Track calibration data, torque specs, and connector integrity, since deviations can invalidate warranty coverage or trigger regulatory flags. Consider warranty implications before initiating work: understand which activities void coverage and which are supported by manufacturers’ guidelines. Ascertain personnel access control, change logs, and traceability are maintained to support audits and recalls if needed. Prioritize transparent communication with fleet operators about compliance status, inspection intervals, and warranty terms to preserve freedom to operate without compromising safety. Regulatory compliance framing reinforces trust and long‑term resilience of repair programs.

Liability Risks and Protective Measures in Repair Processes

Liability risks in repair processes arise when gaps exist between diagnostic conclusions, replacement actions, and requalification results; clear delineation of responsibilities helps prevent ambiguous accountability. You should map every step—from fault identification to final verification—so ownership is explicit and auditable. When gaps appear, responsibilities blur, increasing exposure to claims and regulatory scrutiny. To mitigate risk, require formal repair agreements that define scope, acceptance criteria, and testing protocols, aligning technician actions with manufacturer specifications. Maintain contemporaneous documentation of diagnostics, parts used, and requalification outcomes, and preserve chain-of-custody for any components involved. You should carry liability insurance tailored to repair activities, with coverage expanded to third-party claims arising from improper rework, diagnostic errors, or incomplete requalification. Use risk-aware decision points to pause work if uncertain results emerge, ensuring escalation pathways are clear. In practice, enforce independent verification when complex reseating or recalibration is required, and lock in protective measures before field return.

Preventive Practices and Documentation to Mitigate Liability

Preventive practices and documentation build on the liability controls discussed earlier by codifying proactive steps that prevent failures from becoming claims. You implement preventive maintenance to detect wear, calibration drift, and wiring degradation before they compromise occupancy sensing. Establish a routine schedule, record results, and assign responsibility for follow-up actions to guarantee timely remediation. Documentation practices should capture test procedures, environmental conditions, tool usage, and part specifications to support traceability and accountability. Use objective measurements, clear pass/fail criteria, and dated sign-offs to reduce ambiguity during audits or disputes. Integrate checklists that align with OEM guidelines and safety standards, then archive them in a centralized, access-controlled repository. Regular reviews of historical incidents help you refine maintenance intervals and intervention thresholds. By harmonizing technical rigor with transparent records, you strengthen defenses against liability while preserving operational freedom to adapt procedures as technologies evolve.

Frequently Asked Questions

How Do Seat Occupancy Sensor Repairs Affect Vehicle Resale Value?

The resale impact of seat occupancy sensor repairs depends on repair quality and documentation. If you restore sensor reliability with OEM parts and clear service records, resale value tends to hold steadier. Conversely, improper repairs or missing logs can raise questions about safety and reduce value. You’ll want thorough diagnostics, certified technicians, and transparent reports to demonstrate ongoing safety compliance and sensor reliability to potential buyers.

What Is the Typical Warranty Handling for Replaced Sensors?

You’ll typically receive a warranty covering replaced sensors for a defined duration, often 1–3 years or a set mileage limit, whichever comes first. This reflects sensor reliability and manufacturer standards. You should expect proof of installation, and coverage usually includes defects in materials or workmanship, not accident damage. If you notice issues, contact the installer promptly; documenting symptoms helps guarantee you retain the full warranty duration and support your safety-focused, freedom-minded approach.

Are There Insurance Implications if a Repair Fails Post-Service?

Yes, there can be insurance implications if a repair fails post-service. If the failure results from negligence or improper repair, your insurer may deny coverage or pursue liability. You should document procedures, tests, and components used, and notify your insurer promptly. In insurance claims, precise fault attribution matters for coverage and liability. Be proactive: maintain records, engage qualified technicians, and conduct thorough post-repair testing to minimize potential repair failures and claim disputes.

How Do Privacy Laws Apply to Data From Occupancy Sensors During Repair?

You’ll find privacy laws protect occupancy sensor data, so during repair you must minimize collection, secure transmission, and limit access. Your focus is data protection: scrub nonessential data, anonymize where possible, and log every access. Sensor privacy means using encrypted channels, strict role-based permissions, and prompt deletion of temporary data. You should document compliance checks, carry informed consent where needed, and guarantee contractors follow privacy standards so you retain control and user trust while preserving safety.

What Constitutes Acceptable Risk Transfer in Liability Terms?

You’ll want to know that acceptable risk transfer means clearly defining liability through risk assessment and timing of controls. Approximately 40% of small firms cite contract-based risk shifting as essential, so your approach should align with documented risk assessment findings. You should use liability waivers for defined, non-transferable risks and keep residual risk within agreed tolerances. Don’t neglect ongoing reviews. Think safety-first, yet you preserve freedom by aligning waivers to verifiable risk controls.