Fuel and Battery Care to Stop Frozen Locks and Seals for Long-Term Parked Cars

To prevent frozen locks and seals in long-term parked cars, stabilize fuel and keep it circulating after treatment, avoiding high-ethanol blends for storage. Disconnect nonessential loads and use a smart charger in maintenance mode to hold battery around 80% (AGM) or 90% (flooded). Inspect and lubricate seals, keep bond points clean, and document changes. Schedule monthly fuel and battery checks, top off fuel with stabilizer, drain condensation, and prep the system before spring to safeguard startup—more tips await.

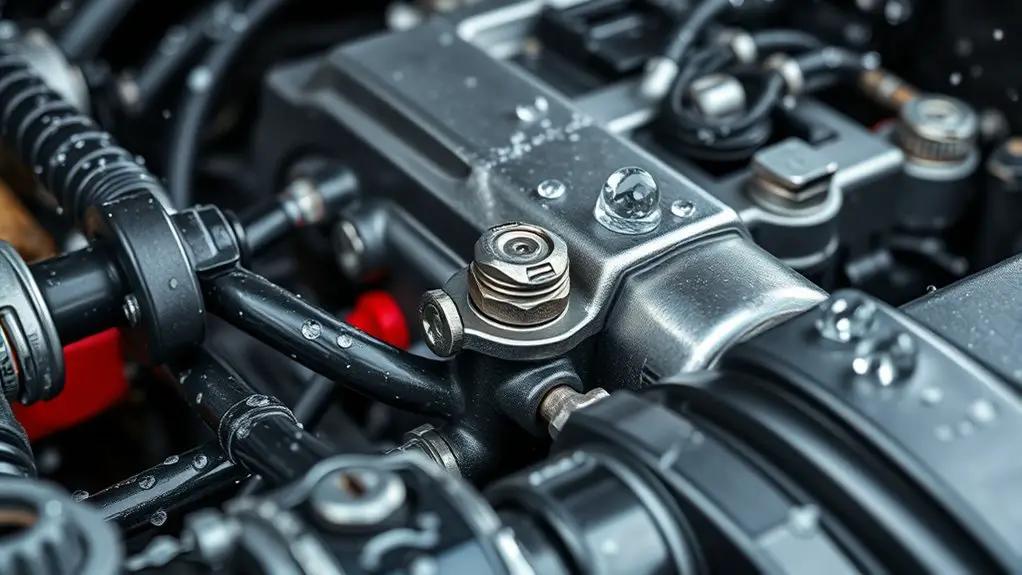

Preventing Fuel Gel and Stabilization Tactics

To prevent fuel gel and maintain performance during long-term storage, add a fuel stabilizer that meets your fuel type’s specifications and run the engine for 5–10 minutes after adding the stabilizer to guarantee the treated fuel circulates. You’ll choose a stabilizer compatible with your gasoline or diesel, then pump in the recommended amount per label. After mixing, start the engine and idle until accessories cycle, ensuring the stabilizer reaches the entire system—fuel lines, injectors, and the tank. This prevents gel formation in cold climates and reduces moisture buildup that spurs corrosion. Track fuel quality by noting storage conditions, avoiding high-ethanol blends if your storage is prolonged, and consider cycling the engine periodically to distribute additives. When you drain old fuel is impractical, supplement with fuel additives designed to inhibit gum and varnish formation. Maintain documentation of types used and batch dates for future reference. Gel formation risks drop when you follow these stabilization practices consistently.

Battery Care and Maintenance for Extended Parking

When a vehicle sits for an extended period, battery health hinges on keeping a stable charge and minimizing parasitic drain; disconnecting nonessential loads, using a smart charger, and recharging every few weeks helps preserve cranking power. You should verify the battery type and ascertain terminals are clean and snug before storage. During the layup, initiate battery charging with a reputable trickle or smart charger set to a maintenance or float mode, matching the battery’s chemistry. Avoid deep discharges; aim for a state of charge around 80% for AGM and around 90% for flooded lead-acid to extend life. Periodically assess voltage and surface charge, and resume charging after every two to four weeks of inactivity. Document charge cycles and any voltage drop, replacing aging cells proactively. Implement clear maintenance techniques: keep connections corrosion-free, protect from extreme temperatures, and use a battery disconnect switch to reduce parasitic drain when possible. This approach sustains readiness and reduces start-up surprises.

Protecting Seals, Gaskets, and Connection Points

Protecting seals, gaskets, and connection points is the natural next step after keeping the battery healthy, since a long-term layup can expose these joints to moisture, temperature swings, and oxidation.

You’ll lock in protection by applying targeted measures that resist leakage and corrosion without complicating future checks. Use seal lubrication techniques to reduce friction and prevent pinhole leaks at door, trunk, and hatch seals. Inspect gaskets for cracking or compression, and plan gasket replacement intervals based on mileage, climate, and rubber age. Keep metal bondpoints clean and lightly coated to deter corrosion, especially where hoses meet housings. Document any seal or gasket changes for quick future reference, and avoid over-application that can attract dirt.

- Seal lubrication techniques for long-term storage

- Gasket replacement intervals and criteria

- Connection-point cleanliness and corrosion prevention

Storage Habits: Fuel and Battery Checkup Schedule

Storage habits for fuel and battery care during long-term storage focus on a precise, repeatable checkup schedule. You’ll calendar a monthly inspection that balances practicality with reliability. Start by evaluating fuel quality: top off to a safe level, add a fuel stabilizer if you expect storage beyond a month, and drain any left-over water condensation from the tank if possible. Check for ethanol content and signs of varnish or sediment in the sump. For the battery, verify terminals are clean and tight, and measure open-circuit voltage. If the vehicle sits beyond a few weeks, consider maintaining a small, controlled surface charge to prevent sulfation and maximize battery longevity. Inspect electrolyte level only if you have a serviceable lead-acid pack, topping with distilled water as needed. Record dates, readings, and actions for traceability. This disciplined routine preserves fuel quality and battery longevity without unnecessary intervention, granting you freedom from surprise failures.

Quick Start-Up Prep Before Spring Return

With a simple, 48-hour prep window, guarantee your parked car is ready for spring by rechecking fuel and battery baselines, then execute a targeted start-up sequence. You’ll perform a quick inspection, verify fluid levels, and confirm no corrosion on terminals. Prioritize a gentle, controlled reactivation to avoid stalling or abrupt loads, ensuring springs, seals, and gaskets regain pliancy without strain. In the start-up, monitor for unusual noises, dashboard warnings, and belt tension, and have a voltmeter ready to confirm >12.6V at rest and a healthy rise during cranking. This quick maintenance phase reduces the risk of cold-start stress and supports spring maintenance momentum, keeping your car ready for freedom on any road.

- Check fuel pressure, battery health, and terminal cleanliness before ignition

- Inspect belts, hoses, and fluid levels during the warm-up cycle

- Confirm engine reaches operating temperature and no leaks or alarms appear

Frequently Asked Questions

How Often Should You Replace Antifreeze for Long-Term Storage?

Antifreeze replacement frequency: check your owner’s manual; many manufacturers suggest renewing every 1 to 3 years for long-term storage. You should test coolant strength, monitor for corrosion, and use the correct mix for your climate. Follow long term storage guidelines: drain and refill if needed, top off with fresh antifreeze, and run the engine to circulate. Do this before storage to prevent freezing, corrosion, and engine damage—keep systems protected throughout.

Will Solar Chargers Affect Battery Warranty During Extended Parking?

Yes, a solar charger won’t void your battery warranty during extended parking if used correctly. You’ll gain solar charger benefits like steady trickle charging and avoidance of deep discharges. To protect warranty, match amperage to your battery’s spec and install with proper timing and routing. Conduct battery maintenance tips such as keep terminals clean and monitor voltage. When used as directed, this free power source supports reliability and freedom, without compromising warranty.

Can Fuel Stabilizers Impact Engine Oil Viscosity?

Fuel stabilizers don’t change engine oil viscosity. They’re aimed at fuel quality, helping prevent degradation and inhibitor loss, not lubricant standards. If you’re storing long-term, focus on oil grade, changes intervals, and ring-seal condition. You’ll maintain engine performance by using the correct viscosity for your climate, checking oil level, and rotating systems. In short: stabilizers won’t alter viscosity, but great storage habits will protect your engine’s performance and freedom to drive.

Do Plant-Based Fuels Cause Seal Degradation Over Years?

Yes, plant-based fuels can affect seal integrity over years, depending on composition and exposure. You should monitor seal materials compatibility with the fuel blend, especially as biodiesel content rises. Track the fuel composition and its lubricity, corrosion inhibitors, and stability. Avoid high biodiesel blends in older seals without testing. Use fuel additives and stabilizers only if compatible with your seals, and reseal or replace parts prone to degradation to maintain seal integrity.

Is There a Recommended Discharge Level Before Long-Term Parking?

Short answer: you should discharge to about 12.6–12.4 volts (or ~50–60% state of charge) before long-term parking for lead-acid; higher for modern AGM or lithium. In practice, aim for a maintenance trickle charger to prevent full discharge. During long term parking, perform battery maintenance by disconnecting nonessential loads and check every 1–2 months. Don’t leave fully charged or fully discharged; protect against corrosion, keep seals dry, and guarantee reliable starts.