How to Diagnose Frequent TPMS Warning and Permanent Solutions

TPMS warnings often come from under- or over-inflated tires, weak or corroded sensors, or a miscalibrated system. Start by checking all tire pressures, including the spare, and note readings. Test each sensor’s battery and transmitter, inspect seals and housings for damage, and verify wheel connections. Recalibrate per your owner’s manual, then relearn the system or replace faulty sensors if needed. Keep documentation handy—this approach reduces repeat alerts and clarifies next steps you’ll take. You’ll uncover more details ahead.

Common Causes Behind Repeated TPMS Alerts

There are several common causes for repeated TPMS alerts, and identifying the exact source helps you fix it quickly. You’ll approach this like a checklist: verify tire pressure first, then inspect sensors and transmitter seals. Begin with tire pressure: confirm all tires are within recommended ranges, including the spare if your system covers it. Low or uneven pressures trigger warnings, so adjust to specification and recheck. If pressures are correct, test for sensor malfunction. Look for corroded or damaged valve stems, leaking seals, or a cracked sensor housing. A weak battery in any sensor can cause intermittent signals; replace failing units as needed. Inspect the monitoring module connections for secure seating and corrosion. Road debris or impact damage can misread data, so inspect wheels, rims, and sensors after a tire service. When in doubt, document readings and proceed with a sensor calibration or professional diagnostic.

How TPMS Works: A Quick Refresher

TPMS Basics Recap: you’ll see how sensors monitor tire pressure and why readings matter. Sensor Signals Overview: you’ll learn how each wheel’s transmitters relay data to the system. Pressure vs Temperature Cues: you’ll note how pressure changes and temperature shifts influence warning thresholds.

TPMS Basics Recap

TPMS, or Tire Pressure Monitoring System, continuously monitors each tire’s air pressure and alerts you if it drops below the threshold. You’ll understand the basics quickly: TPMS sensors reside in each wheel, relaying pressure data to the system’s control module. When a tire inflates or deflates, readings update in real time, triggering a warning if the value is too low or too high. Use this recap to confirm your knowledge before troubleshooting. The goal is steady, reliable tire inflation and accurate alerts, not guesswork. Regular checks guarantee sensors stay synced with your tires, and you avoid unnecessary resets. Keep tire inflation within manufacturer specifications, inspect for punctures, and note warning behavior. This foundation supports precise diagnosis without overwhelm.

Sensor Signals Overview

When a tire’s pressure changes, the sensor transmits data to the control module through a defined signal pattern, enabling the system to distinguish real pressure shifts from sensor noise. You’ll encounter two primary sensor types: indirect and direct. Indirect uses wheel speed data to infer pressure, while direct relies on a physical transducer inside the tire. Each type produces a cadence, amplitude, and error check that the module expects. Be mindful of signal interference from magneto-electric sources, nearby radio devices, or harsh electrical grounds, which can corrupt readings. If you notice inconsistent alerts, verify wiring integrity, antenna positioning, and battery health. Document time stamps, sensor IDs, and fault codes, then test with controlled pressure changes to confirm the signal pattern remains steady under normal conditions.

Pressure Vs Temperature Cues

If you want to understand how temperature affects tire pressure readings, start with the basics: air expands when it gets hotter and contracts when it cools, and TPMS interprets these changes to distinguish genuine pressure shifts from sensor drift. In this scenario, pressure versus temperature cues are your diagnostic compass. As you monitor readings, note how temperature variations drive short-term pressure fluctuations independent of leaks. TPMS uses baseline pressure plus historical trends to separate transient spikes from real losses. When you see simultaneous pressure changes across tires, assess ambient and road temperatures rather than faults. Consistency across cycles signals sensor health; erratic shifts point to calibration or sensor drift. Document conditions, compare to prior data, and prioritize adjustments that minimize false alarms without masking actual pressure issues.

Diagnosing Sensor Battery and Transmitter Issues

To diagnose sensor battery and transmitter issues, start by confirming the battery status and examining the transmitter’s power signal. You’ll want to verify that the sensor’s battery is within its expected lifespan and that the transmitter is broadcasting reliably. Check for corrosion on terminals, guarantee seals are intact, and look for any visible damage to the sensor housing. If the power signal fluctuates or drops, test replacement components in a controlled sequence: replace the battery first, then re-test the transmitter response before considering sensor replacement. Document dates and readings to track sensor lifespan trends. Use manufacturer specifications to determine acceptable voltage ranges and transmitter duty cycles. If persistent faults occur, perform a controlled reinitialization or pair the sensor with the receiver per instructions. Avoid unnecessary disassembly that could void warranties. When battery replacement is required, do so with OEM parts to maintain system integrity and safety.

Checking Tire Pressure Habits and Seasonal Changes

Maintaining consistent tire pressure requires attention to seasonal changes and a routine checks schedule, so start by establishing a baseline pressure for your tires based on the vehicle manufacturer’s specification and the Load or per-tire labeling. You’ll check tire pressure routinely, not just when a warning appears. Use a reliable gauge and measure when tires are cold, before driving more than a mile. Record the exact pressures and compare them to the recommended values, noting any deviations. Seasonal changes matter: colder weather lowers pressure, warmer weather raises it. Inflate to the recommended range, not to the maximum sidewall number, and adjust for load if you regularly carry extra weight. Schedule monthly checks and before long trips. Monitor for slow leaks, valve issues, or damaged stems as you go. Consistency strengthens reliability, reduces uneven wear, and keeps TPMS readings accurate without constant surprises. Prioritize proactive care for tire pressure and seasonal changes.

Wheel Sensor Corrosion and Installation Troubles

Wheel sensor corrosion and installation troubles can disrupt TPMS readings and trigger false warnings. You’ll inspect the wheel sensor area for corrosion on the metal contacts, threads, and mounting flange. Clean corrosion with a non-metallic brush and appropriate contact cleaner, then dry thoroughly before reinstallation. Check seals and o-rings for cracking or deformation; replace as needed to maintain a proper seal and prevent moisture ingress. Verify the sensor’s electrical connector pins are clean, undamaged, and firmly seated; reseat if loose. Confirm the sensor is securely mounted to the wheel with correct torque per manufacturer specs to avoid intermittent signals from vibration. During reinstallation, follow installation guidelines to maintain proper sensor orientation and height relative to the tire bead. Document sensor maintenance and any replacements in the vehicle’s service log. If warnings persist after cleaning and reseating, assess wheel position data for potential misalignment or faulty wiring in the TPMS circuit.

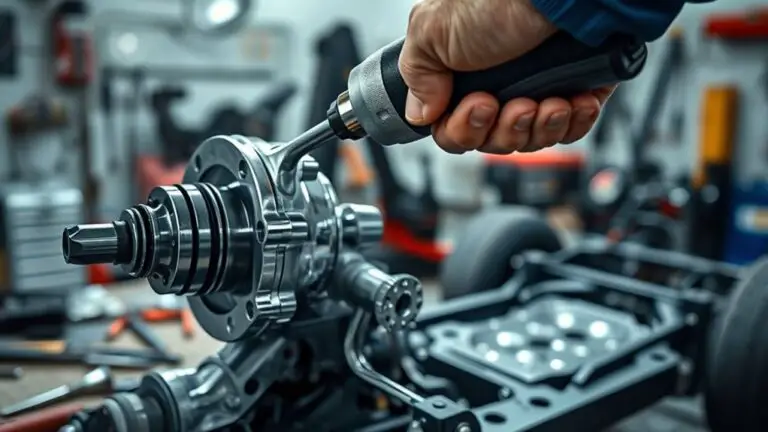

Tools and Safe Methods for TPMS Diagnosis

You’ll start by selecting safe TPMS tools designed for reliability and accuracy. Follow diagnostic best practices to verify sensor data, cross-check with vehicle logs, and document any anomalies clearly. Keep procedures concise and repeatable to guarantee consistent results and safe handling of TPMS components.

Safe TPMS Tools

Safe TPM tools let you diagnose tire-pressure monitoring systems without risking damage or false readings. You’ll use purpose-built readers and mobile apps to access TPMS data, verify sensor IDs, and check wheel integrity. Keep your approach precise: confirm battery status, sensor age, and signal strength before data interpretation. When sensor maintenance is needed, follow manufacturer guidelines to avoid glassy readings or cross‑talk between wheel wells. Use calibrated adapters to seal tires during testing, and document all readings in a tidy log. Favor noninvasive checks first, reserving invasive procedures for clearly justified cases. This approach respects TPMS technology limits while preserving wheel safety. Stay aligned with quality control: verify results, reset as required, and maintain clear records for future diagnostics.

Diagnostic Best Practices

Diagnostic best practices start with a disciplined, noninvasive approach: use approved TPMS tools, verify sensor IDs, and confirm wheel integrity before any data interpretation. You should set baseline readings, guarantee batteries are fresh, and document serials for traceability. Sensor diagnostics require consistent methodology: isolate each tire, perform controlled rotations, and capture real-time data with standardized thresholds. Use troubleshooting techniques to distinguish sensor fault from system wiring or module issues. Record atmospheric conditions, vehicle load, and tire specification to contextualize results. Avoid assumptions; cross-check with known-good values and prior scans. Maintain a clean work area and protect sensors from impact. After data collection, summarize findings succinctly, propose corrective steps, and verify results with a confirmatory test drive.

Permanent Fixes: From Recalibration to Sensor Replacement

When addressing permanent fixes, start with recalibration if the system allows it, then move to sensor replacement only when recalibration fails to restore accurate readings. You’ll verify the vehicle’s TPMS procedure in the owner’s manual, selecting recalibration or resetting options if available, and follow prompts precisely. Document the target pressures and current sensor readings, and perform a controlled road test to confirm stability. If readings remain erroneous, proceed to recalibration techniques that align sensor data with wheel speed and vehicle codes, ensuring you respect manufacturer guidance. Assess sensor compatibility before swapping any unit; confirm part numbers, battery age, and transmission method to avoid mismatches. When replacement becomes necessary, remove the faulty sensor with proper tools, secure the new sensor to the correct position, and recheck all valves and seals. After installation, reprogram or relearn the system as required, then verify consistency across all tires under varying loads. Maintain clear records for future audits.

Preventive Practices to Reduce Future Warnings

Preventive practices start where fixes leave off: maintain calibration readiness and build safeguards that minimize repeat warnings. You’ll establish a routine that supports stable TPMS behavior, not quick fixes. Begin with tire maintenance, ensuring proper tread depth, even wear, and correct pressures per vehicle specs. Regularly verify sensor seal integrity and check for corrosion on valve stems. Document tire changes and remind yourself to recheck after installation. Implement seasonal inspections to catch issues before they trigger alerts: inspect sensors, batteries, and wiring for signs of degradation or exposure to moisture. Use a calibrated gauge for pressure at cold intake, then compare against reference values to confirm accuracy. Schedule reminders for pre-season tire swaps and post-season inspections, aligning them with manufacturer recommendations. When warnings arise, correlate with recent tire work or road impacts and revalidate calibration only after confirming all mechanical factors are addressed. Maintain a simple log to sustain momentum and freedom in driving.

Frequently Asked Questions

How Do TPMS Warnings Affect Tire Warranty Claims?

Echoing a cautionary note, your TPMS warnings can complicate tire warranty claims. You’ll want to document TPMS alerts, when they occur, and any related tire wear or damage. If the system triggered pre-purchase or during use, it may affect coverage or eligibility. Check the tire warranty terms, and report all sensor faults promptly. You’ll improve your claim by proving timely maintenance and proper tire care within warranty guidelines.

Can Aftermarket Wheels Trigger TPMS False Alarms?

Yes, aftermarket wheels can trigger TPMS false alarms. You’ll want to verify wheel compatibility and use aftermarket sensors that match your vehicle’s specs. Check sensor type, stem length, and calibration requirements, then reprogram or relearn the system as needed. Confirm the sensors are compatible with your ECU and wheel setup. If alarms persist, inspect tire pressure, valve cores, and rims for leaks or damage. This keeps your system reliable and your ride unbound.

Do TPMS Faults Impact Fuel Efficiency or Handling?

Yes, TPMS faults can subtly affect handling and fuel efficiency. When tire pressure isn’t ideal, you’ll notice slower steering response, increased tire drag, and uneven wear, all of which can raise fuel use and alter grip. To protect performance, you’ll rely on TPMS technology to warn you about under-inflation and adjust tire pressure promptly, ensuring tire pressure is correct and handling remains precise under varying loads and speeds. Stay vigilant, adjust, and drive with freedom.

Are TPMS Alerts a Safety Risk During Driving?

Yes, TPMS alerts can be a safety risk if ignored or faulty. When you see a warning, don’t delay—check tire pressure, inspect for damage, and service if needed. TPMS accuracy concerns exist, so don’t assume it’s always precise. Treat these alerts as a vital safety feature importance cue, not an optional notice. You should verify readings with a manual gauge and consult a pro. Stay proactive, and drive with reliable, properly inflated tires.

How Often Should TPMS System Software Be Updated?

You should perform TPMS software updates whenever the system prompts you or when the manufacturer recommends it. Regular system updates help maintain tire pressure accuracy and fault tolerance. Check for updates at least once a year, or after service intervals that involve tire work or sensor replacements. Treat TPMS software as essential, using official sources for downloads. Keep your vehicle’s tech fresh, and you’ll preserve safety, reliability, and performance with timely system updates.