How to Interpret Complex Electrical Gremlins When Scanning a Modern OBD-II Cars

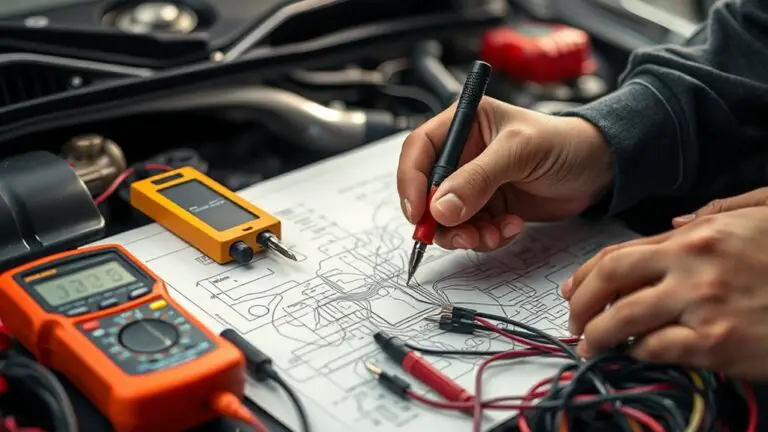

When you scan a modern OBD-II car, you decode the language of codes, live data, and freeze-frame snapshots into a wiring blueprint. Start by logging DTCs and their suffixes, then validate with real-time sensor streams against specs. Use freeze-frame context to confirm conditions at failure. Map each symptom to circuits, sensors, and ECM logic, prioritizing intermittent or high-risk issues. Avoid premature parts swaps by correlating signals, and stay ready to escalate if patterns point to harness or grounding faults—the deeper mapping awaits you.

Reading Diagnostic Trouble Codes: Decoding the Language of Your Car

Reading Diagnostic Trouble Codes (DTCs) is the first step to translating your car’s fault signals. You’ll learn how DTC definitions map to symptoms, so you can diagnose without guesswork. Begin with code categories—powertrain, body, chassis, and network—so you know the broad area behind the fault. You’ll also encounter vehicle specific codes, which require your exact make, model, and year to interpret accurately. When you pull codes, note the numeric value and any alphanumeric suffixes; those details sharpen your focus. Interpreting severity becomes your next discipline: some codes signal imminent danger, others point to minor annoyances or pending issues. Maintain a disciplined log of codes, freeze-frame data, and timestamps to assess patterns over time. This approach preserves your freedom to troubleshoot on your terms, without endless mystery. By mastering definitions and categories, you set the stage for precise, actionable diagnostics.

Interpreting Live Data Streams: Seeing the System in Real Time

Live data streams turn the car’s nervous system into a real-time waveform you can read. You’ll learn to track voltages, currents, and sensor outputs as they shift under load, giving you direct insight into cause and effect. Focus on consistency, reference ranges, and how small deviations signal faults before codes appear. Real time monitoring empowers you to verify repairs and spot creeping drifts that precede failures.

- Compare live data to manufacturer specs and your own baseline for quick fault discrimination

- Observe how sensors respond to RPM, throttle input, and load to distinguish bad hardware from poor wiring

- Correlate multiple parameters in real time to confirm root cause instead of chasing symptoms

Use structured notes, capture timestamps, and save traces for later review. Stay disciplined: avoid assumptions, document every anomaly, and validate with repeat runs. With live data analysis, you keep the system honest and your freedom intact.

Analyzing Freeze-Frame Data: Contextual Snapshots for Troubleshooting

Freeze-Frame data captures the exact moment a fault occurs, so you’ll map the context to specific faults using Freeze-Frame Context and Snapshot Troubleshooting principles. You’ll correlate sensor states, PID values, and event timestamps to pinpoint causality and separate transient glitches from root causes. Use these snapshots to guide targeted tests and confirm with Data Correlation Techniques before proceeding with repairs.

Freeze-Frame Context

When a fault occurs, the ECU saves a freeze-frame snapshot that captures engine conditions at the moment of failure. You’ll use this contextual data to validate symptoms, isolate faulty subsystems, and confirm whether readings align with the reported fault. Treat the frame as a precise reference: rpm, load, temperatures, and sensor states are your variables, not guesses. Freeze frame analysis guides you to the core issue, reducing diagnostic drift and speeding decisions. Its diagnostic relevance lies in cross-checking real-time behavior against stored values, revealing anomalies that persistent data may miss.

- Isolate abnormal sensor states at failure

- Correlate rpm, temperature, and requested torque

- Confirm consistency with fault codes and live data

Snapshot Troubleshooting

With a fault code and freeze-frame in hand, snapshot troubleshooting focuses on extracting meaning from the stored context. You systematically identify parameters captured at the moment of failure, separating normal from anomalous values. Start by listing sensor readings, ignition status, and RPM, then compare against baseline expectations. Use snapshot analysis to detect timing correlations: when did the event occur relative to shifts in load, speed, or temperature? Filter out transient noise to reveal true causality. Apply targeted troubleshooting techniques: confirm fuel pressure, verify injector duty cycle, and check ignition coil health within the captured window. Document deviations clearly, then reproduce under controlled conditions to validate findings. This disciplined approach yields actionable insights without guesswork, empowering you to trace gremlins efficiently and with confidence.

Data Correlation Techniques

To extract meaning from freeze-frame data, you correlate the stored snapshots with real-time conditions and system expectations. You then apply data patterns to identify anomalies and align them with fault codes, sensor limits, and actuator states. Use straight-line reasoning: map timestamped values to operating modes, then isolate deviations that recur under specific loads or temperatures. Correlation methods blend trend analysis with cross-channel checks, confirming cause–effect rather than coincidence. Your goal is reproducible insight, not guesswork. Document the exact sequence, inputs, and thresholds that produced the snapshot, so future sessions mirror this process. Remain skeptical of single-point spikes; prioritize consistent patterns across cycles.

- data patterns

- correlation methods

- cross-channel validation

Mapping Symptoms to Circuits, Sensors, and ECM Logic

Directly link the symptom you’re observing to the circuit, sensor, or ECM logic that could be responsible, then map that link to testable checks. You’ll trace a symptom to a high-probability circuit path, then confirm with targeted inspections and measurements. Start with circuit behavior: look for open/short conditions, grounding integrity, and supply voltage stability. Next, assess sensor reactions: verify response time, scaling, and electrical noise. Finally, connect to ECM logic: confirm proper input interpretation, fault codes, and LIN/CAN messaging integrity. Use controlled tests to separate mechanical from electrical causes, and document each finding with clear pass/fail criteria.

| Symptom / Link | Test to Perform | Expected Result |

|---|---|---|

| Misfire suspect → injector circuit | Check injector PWM, supply voltage | Stable duty cycle, no dropouts |

| Sensor latency → MAP/MAF | Observe live data, compare to reference | Real-time response within spec |

| Ground drift → ECM input | Measure ground impedance | Low impedance, solid return |

| Voltage spike → power rail | Scope rail during load | No transients beyond spec |

| CAN message delay → ECM logic | Log bus timing, node responses | Timely, consistent frames |

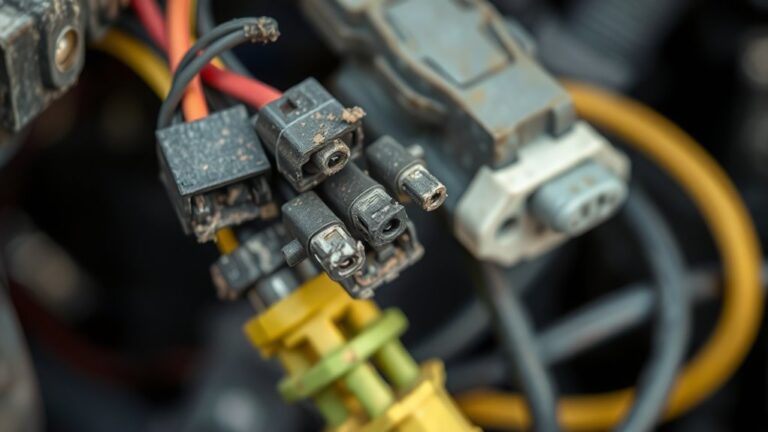

Common Gremlin Patterns in Modern OBD-II Systems

Modern OBD-II systems show recurring gremlin patterns that can mislead diagnostics if not recognized early. You’ll spot reliable templates that recur across makes, models, and generations, so learning them sharpens gremlin identification and speeds resolution of electrical anomalies.

- Intermittent signals that vanish with load changes

- Sensor readings drifting without fault codes

- Harsh revert/latency in actuator responses despite normal static tests

These patterns aren’t random; they map to wiring harness health, connector integrity, and ECM timing quirks. When you encounter them, document symptom onset, voltage rails, and grounding quality, then correlate with fault codes and live data. Expect nested causality: a single loose pin can mimic multiple failures, and a faulty ground can skew several sensors. Your goal is to distinguish true failures from phantom readings by tracing symptoms back to a likely circuit or connector. With disciplined gremlin identification, you convert confusion into a focused diagnostic path and minimize wasted effort amid electrical anomalies.

Safe Reproduction of Electrical Anomalies: How to Trigger Symptoms Responsibly

When you’re reproducing electrical anomalies, do it with a controlled, repeatable method that preserves safety and traceability. You’ll aim for deliberate, documentable symptom exposure that avoids collateral risk. Establish a test plan: defined scope, baselines, and rollback steps. Use non-destructive stimuli, verify with independent measurements, and log every parameter. Practice responsible triggering by limiting variables and maintaining a clear authorization trail. Focus on symptom simulation that mirrors real-world behavior without inducing random faults. Validate with redundancy—two independent sensors or references—before conclusions. Keep peer review on standby and suspend tests if safety thresholds are breached. After each run, restore normal conditions and annotate results for future audits. This discipline preserves trust, reduces damage, and supports learning.

| Visual cue | Practical note |

|---|---|

| Trigger & verify | Documented, repeatable steps |

Systematic Workflow for Prioritizing Faults Without Overwhelm

A systematic workflow for prioritizing faults avoids overwhelm by separating issues into manageable tiers and applying objective criteria to rank urgency and impact. You’ll map symptoms to a tiered plan, then quantify risk using data you already collected from scans and logs. Establish entry points for triage, then escalate only cases that meet hard thresholds. This approach relies on fault prioritization strategies that favor corrective action with clear justification, not guesses. Use diagnostic flowcharts to guide each decision, ensuring repeatable, auditable steps and enabling calm, deliberate action.

A disciplined, tiered fault workflow prioritizes safety, criticality, and evidence-backed escalation.

- Prioritize by safety impact, system criticality, and likelihood of fault progression

- Validate with objective tests before escalation

- Document decisions for traceability and knowledge reuse

This mindset preserves autonomy while delivering disciplined results, so you can troubleshoot confidently without chaos. Maintain focus on verifiable signals, avoid assumptions, and let structured reasoning define the pace of progress.

Practical Techniques for Correlating Symptoms With Wiring and Sensors

You’ll start by mapping symptoms to likely signal paths, so you can pinpoint where readings diverge from expectations. Next, apply sensor-wiring correlation to confirm whether a fault travels with a wiring harness or stays with the sensor itself. Finally, outline concise diagnostic test strategies that validate Symptom-to-Signal mapping and tighten confidence in the root cause.

Symptom-to-Signal Mapping

Symptom-to-signal mapping begins by listing observed issues and tracing them to likely electrical causes through a disciplined, evidence-driven approach. You map symptoms to probable faults with clear rationale, separating noise from meaningful patterns. Focus on symptom identification and signal analysis to build a defensible chain from vague complaint to testable hypothesis.

- Correlate each symptom with a plausible signal pattern you can measure

- Record timing, duration, and sequence to reveal causality

- Use simple tests to confirm or refute hypotheses without overcomplicating the dataset

Maintain strict documentation and reproducibility; avoid assumptions unsupported by data. You’ll refine the signal map as you gather evidence, prioritizing issues that reveal diagnostic confidence, while preserving your autonomy to pursue alternative explanations when data justify it.

Sensor-Wiring Correlation

Sensor-wiring correlation builds on the mapped symptoms by directly linking observed faults to the physical wiring and sensor signals. You’ll trace fault portals from the controller to each sensor node, confirming consistent voltage, ground references, and signal amplitudes across harnesses. Begin with sensor identification, cataloging each device and its expected range, then compare actual readings under steady and load conditions. Inspect insulation integrity, connector crimps, and pin continuity to rule out contact resistance as a false signal. Document discrepancies where wiring or shielding could modulate signals, and flag intermittent connections before chasing software quirks. Prioritize consistency: repeat tests, isolate harness segments, and verify alternative paths. This disciplined approach minimizes misdiagnosis and preserves system behavior as you evaluate sensor wiring integrity and correlations.

Diagnostic Test Strategies

When diagnosing OBD-II anomalies, start with repeatable, controlled tests that tie symptoms to actual electrical behavior rather than impressions. You’ll use diagnostic tools to map symptoms to wiring and sensors, enabling precise fault isolation. Approach each test with a clear hypothesis, document results, and roll back assumptions as data shifts. Prioritize reproducible conditions, isolate abnormal circuits, and confirm with a second method before concluding. This strategy reduces guesswork and speeds resolution without chase.

- Establish baseline electrical behavior with known-good conditions

- Correlate sensor signals to actuator responses using multiple tools

- Verify fault isolation by swapping, simulating, or restoring normal wiring

This disciplined method delivers freedom through clarity, ensuring you fix the gremlins without unnecessary detours.

Avoiding Unnecessary Parts Swaps: Distinguishing Noise From Real Faults

Often, what looks like a fault is just electrical noise or intermittent grounding issues, so you should vet each candidate fault before swapping parts. In practice, you use fault isolation techniques to separate genuine faults from noise. Treat every anomaly as a hypothesis, not a conclusion. Begin with repeatable tests: replicate the condition, record data, and confirm consistency across cycles. If symptoms appear sporadically, inspect grounding paths and harness integrity first, since poor contacts mimic sensor faults. Employ noise filtering methods to differentiate legitimate signals from EMI or voltage glitches. Apply decoupling, shielding, and proper wiring routing to minimize interference before you consider component swaps. When a fault survives controlled rechecks and isolated tests, then proceed with targeted replacements. Document thresholds, test results, and environmental factors. The goal is predictable, minimal interventions—save parts for proven faults and maintain system freedom through disciplined diagnostics.

From Diagnosis to Fix: Turning Data Into Actionable Repairs

You’ll translate the data you’ve collected into a clear action plan by linking each diagnostic result to a concrete repair step. Focus on data-driven diagnostics to prioritize fixes and map them to specific components or circuits. Then translate those findings into actionable repair steps with measured timelines and success criteria.

Data-Driven Diagnostics

Data-driven diagnostics turn measurements into actionable repairs by translating sensor data, fault codes, and drive history into prioritized fixes. You assess data integrity, validate streams, and rank issues by impact, ensuring diagnostic efficiency without guesswork. This approach turns clutter into clarity, guiding you from symptom to solution with repeatable steps.

- data validation checks that inputs are timely, consistent, and credible

- diagnostic efficiency focuses on high-impact faults first, reducing downtime

- historical drive data contextualizes current readings for accurate prioritization

You maintain a disciplined workflow: capture, verify, correlate, and prioritize. You track confidence levels and document rationale, so future scans reuse insights. Freedom comes through control: you set clear goals, avoid overdiagnosis, and rely on data-led decisions rather than emotion or assumption. This method keeps you proactive, precise, and adaptable in the face of evolving gremlins.

Actionable Repair Mapping

Actionable Repair Mapping translates diagnosis into a prioritized, stepwise plan for fixes, linking each fault to a concrete repair action. You convert observations into a clear sequence: identify highest-impact faults, isolate root causes, and align actions with system dependencies. Begin with troubleshooting strategies that validate symptoms, exclude false positives, and confirm fault consistency before touching hardware. Next, assign repair prioritization by risk, safety, and cost, focusing on fixes that restore critical function first. Document each step with expected outcomes, required tools, and time estimates, so you can monitor progress and adjust as needed. Maintain a modular mindset: complete one repair, test, then proceed. This approach reduces regressions, accelerates repair cycles, and preserves your freedom to iterate solutions without unnecessary constraints.

Frequently Asked Questions

How Reliable Are Generic Scanner Codes Across Makes?

Generic scanner codes aren’t highly reliable across makes; you’ll encounter limitations. You’ll notice generic scanner limitations mean codes can mislead you if you ignore vehicle-specific data. Car make differences matter; you’ll see different fault definitions, freezes, and readiness statuses. Approach with a methodical mindset: verify with live data, cross-check with manufacturer codes, and respect diffuser prompts. You crave freedom, but you’ll diagnose precisely, documenting limits and confirming findings before repairs.

Can Gremlins Mimic Multiple Faults Simultaneously?

Yes, gremlins can mimic multiple faults simultaneously. You’ll notice symptom overlap where a single fault cascades into several readings. Start with fault isolation by tracing each symptom to its most probable cause, then rule out shared sensors and wiring. Systematically test in a controlled sequence, confirm with live data, and avoid jumping to conclusions. Anachronism: you’ll treat the CU like a trusty dial-up modem—old school, precise, and stubbornly revealing truth.

Do All Data Streams Require the Same Sampling Rate?

No, not all data streams require the same sampling rate. You tailor data sampling to each signal’s dynamics and diagnostic tool capabilities. You’ll test sensor accuracy across ranges, adjust sampling intervals, and verify vehicle communication reliability. Keep a methodical approach: document rates, compare with baseline, and watch for aliasing or missed events. This freedom to optimize guarantees precise fault isolation while your diagnostic tools maintain robust, real-time insight into the system’s behavior.

Are There Risk-Free Methods to Induce Symptoms?

No, there aren’t risk-free methods to induce symptoms. You should avoid inducing faults yourself. For safe testing, rely on manufacturer guidance, diagnostic tools, and controlled simulations. Document observed behaviors, verify with known-good baselines, and isolate causes methodically. Use proper safety procedures and protective gear, and never poke at live circuits without authorization. If you’re in doubt, pause, consult a qualified technician, and proceed only with approved testing protocols.

How to Distinguish Sensor Drift From Intermittent Faults?

Like a tightrope walker calibrating wind, you distinguish sensor drift from intermittent faults by rigorous trend analysis. Start with sensor calibration: log readings over time, note gradual shifts versus sharp jumps. Then track fault frequency with reproducible tests, differentiating sporadic spikes from consistent patterns. Compare live data against expected behavior, isolate cyclic vs random events, and confirm with reinitialization. If drift persists, recalibrate; if stochastic, inspect wiring and connectors for intermittent contact.