How to Source the Right LED Light Bars to Minimize Wheel Fitment Rubbing on a Tow Rig

To source the right LED light bars and minimize wheel rub on a tow rig, start with precise bar size selection that fits your bumper and fender geometry, then opt for low-profile mounting and adjustable brackets that preserve suspension travel. Align bar length to avoid tire contact at full steering and use rigid, corrosion‑resistant mounts. Verify ground clearance post‑install and test with dynamic wheel motion. For step‑by‑step specifics, you’ll uncover more as you continue.

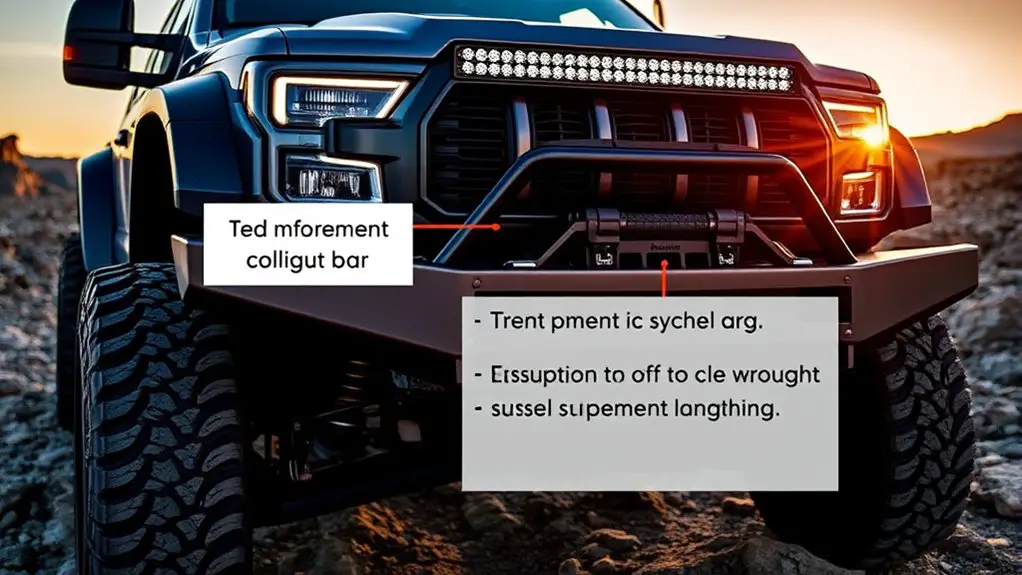

Understanding Bar Size and How It Affects Clearance

When selecting LED light bars for tow rigs, bar size directly determines clearance under overhangs, antennas, and mounting hardware. You’ll evaluate bar dimensions against vehicle geometry to prevent interference with existing components. Start with the nominal bar length, width, and height, then assess overall footprint in real-world mounting positions. A precise clearance analysis accounts for bumper contours, fender lines, and any auxiliary equipment that projects outward. Consider how lens curvature and extrusion profile interact with protective grilles, fairings, and wiring harness routing. Material finish and mounting flange thickness influence how far the bar sits from critical surfaces, so check vertical and horizontal tolerances in your installation plan. Document measurements, tolerance stacks, and potential hot spots where heat or vibration could affect performance. This approach yields reproducible results, supports safety compliances, and guarantees you select bar dimensions that preserve serviceability and peak illumination.

Mounting Options That Minimize Wheel Rub

Mounting options that minimize wheel rub start by aligning bar placement with tire and fender geometry to maintain clearance across suspension travel and steering input. You’ll prioritize mounting locations that preserve full range of motion, avoiding contact under compression and articulation. Evaluate fender lip height, inner wheel arch clearance, and axle toe-in shifts to choose positions that reduce lever-induced contact during full lock and rebound. Bracket styles matter: select rigid, vibration-damped mounts with low-profile footprints to minimize rim exposure while resisting fatigue. Use paired, symmetrical brackets to balance loads and maintain consistent bar orientation relative to the vehicle’s longitudinal axis. Ascertain fasteners are rated for exterior exposure and torque-to-yield safety specs, with captive nuts or welded inserts as appropriate for permanent installs. Recheck ground clearance after suspension travel tests, road debris impacts, and load changes. Document mounting coordinates for serviceability, and verify that wiring routes remain isolated from moving components.

Beam Patterns That Suit Tow Rigs and Road Conditions

Beam patterns for tow rigs must prioritize long-range visibility and road-surface illumination under variable conditions, including high-speed highway travel and urban night driving. You’ll optimize beam patterns to balance throw and front-plane coverage, ensuring critical objects are detected early without excessive glare. Focus on beam width and light intensity to maintain control across mixed terrain, rain, and dust. Narrow throw is essential on open roads, while a controlled wide pattern aids cornering and street-level scanning. Align optics to minimize wheel rub clearance impacts, and verify cutoff sharpness to reduce glare for oncoming traffic. Proper beam profiling reduces fatigue and enhances braking reaction time. Choose patterns with adaptive or multi-beam capability for dynamic conditions, and confirm compatibility with your bar’s mounting geometry.

- Beam width optimization for highway and urban use

- Light intensity management at varying distances

- Cutoff control to reduce glare

- Adaptive/multi-beam configurations for versatility

Materials and Build Quality for Towing Stress

Materials and build quality directly impact towing durability and failure risk under load. You evaluate chassis rigidity, housing seals, and mounting hardware for real-world stress. Prioritize corrosion resistance and UV stability in exterior finishes to maintain integrity under vibration, spray, and road debris. Look for adherence to durability standards from reputable manufacturers, including ingress protection ratings and thermal management strategies that prevent hot spots during continuous use. The LED bar should employ anodized or stainless components where contact surfaces face load transfer, with reinforced end caps to resist torsional flex. Wiring harnesses require strain relief, braid shielding, and certified connectors to endure repeated flex cycles without insulation breach. Weight considerations matter: heavier assemblies can alter suspension dynamics and wheel load distribution; lighter, purpose-built designs reduce peak stresses while maintaining impact resistance. Confirm serviceability, standardized replacement parts, and documented test results to support predictable performance under towing conditions.

Measuring Clearance and Verifying Fitment on Your Rig

Before you install the LED bar, confirm that your rig’s geometry has adequate clearance and proper fitment. You’ll verify spatial tolerances with precision, using clearance tools and disciplined measuring techniques to prevent rubbing, interference, or vibration. Establish a baseline by measuring wheel, fender, and bumper offsets, then compare to the bar’s mounting plane and bracket spread. Document any deviation and plan corrective steps before full install.

1) Establish reference points on the chassis and wheel well; record with calibrated tools.

2) Measure mounting plane, including bolt circle, offset, and centerline alignment, validating clearance to moving components.

3) Recheck after temporary hardware installation; assess dynamic clearances under suspension travel and articulation.

4) Validate final fit with a test-run procedure, noting any contact heat, flex, or noise and adjusting as needed.

Sourcing, Bracket Compatibility, and Field Testing Steps

Sourcing the LED light bar and compatible brackets starts with a clear specification of requirements and strict supplier vetting; you’ll verify part numbers, warranty terms, and compliance with industry standards before any purchase. You’ll map bracket types to mounting geometry, weight capacity, vibration tolerance, and corrosion resistance, then align with tow-rig frame traits. Source with disciplined criteria: certified brackets, compatible bolt patterns, and documented load ratings. Identify sourcing suppliers that offer traceable QC, supplier audits, and clear aftermarket support. Evaluate harness compatibility, weather sealing, and pass-through options to maintain electrical integrity. Use a formal request-for-quote process to compare pricing, lead times, and return policies without compromising safety. For field testing, plan progressive steps: fitment checks, torque verification, and dynamic testing under load, with documented results. Verify bracket integrity after simulated off-road conditions. Document the entire lifecycle, preserving install-revision records for future maintenance and upgrades.

Frequently Asked Questions

Do LED Bars Affect Electrical Load on the Tow Vehicle?

LED bars do affect electrical load on your tow vehicle, but impact varies with spec. If you’ve got high‑duty LEDs, total draw can raise alternator and battery strain under peak demands, especially with auxiliary circuits running. In practice, LED efficiency and proper power management minimize draw, while surge protection and fused circuits safeguard wiring. Verify current needs, use appropriate gauges, and balance with vehicle capacity. This keeps lighting reliable, safe, and compliant for demanding off‑road use.

How Do Temperature Changes Affect Bar Performance and Clearance?

Temperature changes affect bar performance primarily through thermal expansion and contraction, altering clearance to wheels and mounting brackets. You’ll see a measurable temperature impact on bar housing, mounts, and through-bolts; design should accommodate this with proper tolerances and standoff tolerances. Consider thermal expansion coefficients of materials, venting, and torque specs to maintain safe clearance. Use impact-rated, vibration-damped mounts and verify in varied ambient temps to guarantee consistent performance and safety under load.

Are There Legal Height or LED Compliance Limits for Tow Rigs?

No, you don’t get to ignore legal regulations—there are height restrictions and LED compliance rules you must follow. You should verify local, state, and federal transit and vehicle codes, plus tow rig-specific standards. Check highway authority markings, passenger-vehicle lighting rules, and bumper/beam specs. You’ll need certified components, proper mounting, and maintenance logs. Adhere to legal regulations to avoid fines, guarantee safety, and keep your rig within permitted height and illumination limits.

What Maintenance Schedules Minimize Corrosion on Mounting Brackets?

You should implement a maintenance schedule that prioritizes corrosion prevention and monitoring of bracket materials, inspecting for pitting, galvanic reactions, and fastener integrity every 90 days or after exposure to salt. Clean and dry all mounting surfaces, apply corrosion-inhibiting coatings, and replace degraded brackets promptly. Tighten to spec, use anti-seize on critical threads, and document all service intervals. This safety-focused routine protects structural performance while preserving freedom to operate.

Can Aftermarket Bars Void Towing Equipment Warranties or Insurance?

Impact begins the moment you install aftermarket bars: warranty implications and insurance considerations hinge on manufacturer terms and proper installation. You won’t automatically void every warranty, but improper mounting, non-OEM components, or bypassing harness safeties can trigger coverage gaps. If you follow certified kits, maintain documentation, and comply with towing specs, your risk stays controlled. Verify with the OEM and your insurer; keep install receipts, torque specs, and fault codes for clear evidence of compliant practice.