How to Trace Intermittent Loss of Power While Driving Using a Heat Shrink Kit

To trace intermittent power loss while driving, start by inspecting all electrical connections using a heat shrink kit. Look for loose or damaged connectors, slide the heat shrink tubing over them, and apply heat to secure a tight seal. Test wiring for continuity with a multimeter, addressing any frayed insulation or corroded connectors. Regular inspections of connections enhance vehicle performance. There’s more to uncover about preventing future issues and ensuring reliability.

Understanding Intermittent Power Loss

When you’re driving and experience intermittent power loss, it can be frustrating and concerning, especially since it may indicate underlying issues with your vehicle’s systems. Intermittent power loss refers to a temporary reduction in engine performance, which can affect acceleration and overall drivability. This issue may arise from various components, including fuel delivery systems, electrical systems, or sensors.

To address intermittent power loss effectively, conducting thorough vehicle diagnostics is vital. Start by scanning your vehicle’s onboard computer for any diagnostic trouble codes (DTCs). These codes can pinpoint specific areas needing attention, allowing for a targeted approach to troubleshooting. Pay close attention to patterns in power loss, such as when it occurs—during acceleration, deceleration, or idling, as this can guide you to the root cause. By systematically analyzing the data, you can regain control over your vehicle’s performance and guarantee a safer driving experience.

Common Causes of Power Loss in Vehicles

Intermittent power loss in vehicles can stem from several common causes, each requiring careful examination to guarantee reliability. One significant factor is the fuel system; issues like clogged fuel filters or failing fuel pumps can restrict fuel flow, disrupting engine performance. If you’re experiencing power loss, inspect the fuel injectors and verify they’re functioning correctly, as they play a crucial role in delivering the right amount of fuel for combustion.

Another critical aspect is the ignition system. Faulty spark plugs, ignition coils, or wiring can lead to incomplete combustion, resulting in a noticeable drop in power. It’s important to check these components for wear and proper connections.

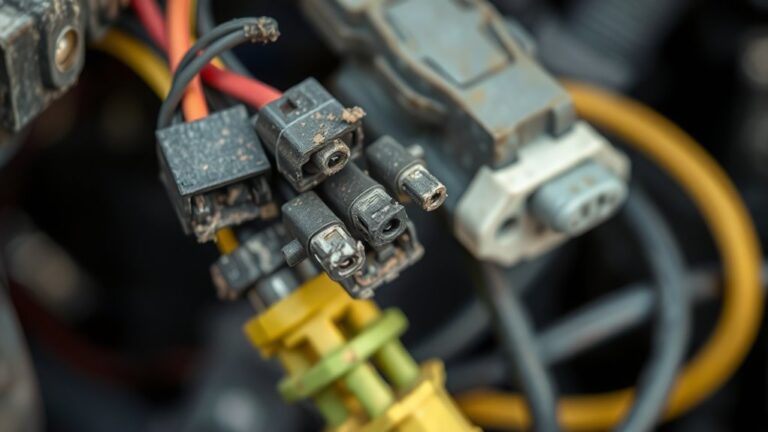

The Role of Electrical Connections in Vehicle Performance

Electrical connections greatly influence vehicle performance, often serving as the backbone of various systems within the car. When you drive, these connections guarantee that power flows efficiently, affecting everything from the ignition system to the fuel injectors. High electrical resistance can compromise this flow, leading to power loss or erratic behavior. You might notice that a faulty connection results in poor acceleration or stalling.

Maintaining connection integrity is vital; even a small corrosion or a loose wire can create significant issues. Regularly inspecting your vehicle’s electrical connections can help you identify potential problems before they escalate. Pay attention to the quality of the connectors and the condition of the wiring, as these factors directly impact your vehicle’s reliability and performance. By guaranteeing robust electrical connections, you not only enhance your driving experience but also maintain the freedom that comes with a well-functioning vehicle.

What Is a Heat Shrink Kit?

A heat shrink kit consists of various tubing sizes, adhesives, and application tools designed for effective electrical insulation and protection. Understanding the components and benefits of these kits is essential for maintaining reliable connections in your vehicle’s electrical system. Next, we’ll explore the application techniques to guarantee peak performance.

Components of Heat Shrink

Heat shrink kits are vital tools for anyone working with wiring and connections. These kits typically include various heat shrink types, such as standard, dual-wall, and adhesive-lined options. Each type serves specific heat shrink applications, ensuring maximum protection and insulation for your wiring. Standard heat shrink offers basic insulation, while dual-wall provides added moisture resistance, making it suitable for outdoor use. Adhesive-lined heat shrink, on the other hand, creates a waterproof seal, ideal for important connections exposed to harsh environments. Additionally, most kits contain a heat gun or other heating tools, allowing you to shrink the tubing uniformly. Understanding these components is significant for effectively addressing intermittent power loss in your vehicle’s electrical system.

Benefits of Using Kits

Using a heat shrink kit offers numerous advantages for anyone addressing wiring issues, especially in vehicle electrical systems. The kit advantages include efficient insulation, protection against moisture, and enhanced durability of connections. Here are some key benefits:

- Repair Convenience: Heat shrink tubing simplifies the repair process, allowing you to quickly seal connections without soldering.

- Temperature Resistance: These kits withstand high temperatures, ensuring your repairs remain intact under varying conditions.

- Professional Finish: Using a heat shrink kit provides a clean, polished look to your repairs, which can enhance reliability.

Application Techniques Explained

While addressing wiring issues in your vehicle, understanding what a heat shrink kit entails is crucial for effective application. Heat shrink kits provide a reliable solution to protect and insulate wires, guaranteeing they perform at their best. Here are key application methods and heat shrink techniques to keep in mind:

| Application Method | Description |

|---|---|

| Clean the Surface | Verify wires are free of dirt and grease. |

| Cut to Length | Measure and cut heat shrink tubing accordingly. |

| Heat Application | Use a heat gun to evenly shrink the tubing. |

| Cool Down | Allow the tubing to cool for a secure fit. |

Mastering these techniques can enhance your vehicle’s electrical integrity, offering you the freedom to drive without power interruptions.

Preparing for Your Investigation

Before you start your investigation, gather the necessary tools, such as a multimeter, wire strippers, and heat shrink tubing. Next, inspect all electrical connections for signs of wear or corrosion that could contribute to power loss. This methodical preparation will facilitate a thorough examination of the issue at hand.

Gather Necessary Tools

To effectively diagnose intermittent loss of power while driving, you’ll need to gather a specific set of tools that will aid in your investigation. Confirming you have the right equipment is vital for both safety and accuracy. Here’s a list of essential items:

- Multimeter: For checking voltage and continuity in electrical circuits.

- Heat Shrink Kit: To secure and insulate any repaired connections effectively.

- Safety Equipment: Such as gloves and goggles to protect yourself during the process.

Having these tools ready will empower you to plunge into your investigation with confidence. Remember, a well-prepared approach not only enhances your troubleshooting capabilities but also guarantees you’re working safely and efficiently.

Inspect Electrical Connections

Electrical connections in your vehicle are essential for ideal performance, and inspecting them is a key step in diagnosing intermittent power loss. Start with a thorough visual inspection of all wiring and connectors. Look for signs of wear, corrosion, or loose connections that could compromise connection integrity. Pay attention to areas where wires may rub against metal surfaces, as this can lead to insulation damage. Use your tools to gently wiggle connectors and check for any movement that may indicate a weak link. Document any findings meticulously, as this will guide your next steps. Ensuring every connection is secure and free from damage can restore your vehicle’s power and enhance your freedom on the road.

Using a Heat Shrink Kit to Inspect Connections

One effective method for inspecting connections in your vehicle’s electrical system is by using a heat shrink kit. This kit helps guarantee that your electrical connections are well-insulated and protected from environmental factors that can cause intermittent power loss.

To effectively use a heat shrink kit, follow these steps:

- Identify the connections: Locate any loose or damaged connectors that may be causing issues.

- Apply heat shrink tubing: Slide the tubing over the connection and use a heat source to shrink it, providing robust electrical insulation.

- Inspect for integrity: Once cooled, check the shrink tubing for a tight seal, guaranteeing no moisture or dirt can compromise the connection.

Testing for Faulty Wiring and Connections

Testing for faulty wiring and connections is essential in diagnosing intermittent power loss while driving. Start by inspecting all visible wiring for damage. Look for frayed wire insulation or signs of corrosion on faulty connectors. Use a multimeter to check for continuity; if you find breaks, it’s time to replace the damaged sections. Conduct a visual inspection under the hood and in the cabin, focusing on areas prone to wear and tear.

| Issue | Symptoms | Action Required |

|---|---|---|

| Frayed Wire Insulation | Flickering lights, power loss | Replace affected wires |

| Corroded Connectors | Intermittent failures | Clean or replace connectors |

| Loose Connections | Engine stalling, erratic power | Tighten or re-solder |

Tips for Preventing Future Power Loss Issues

To guarantee you don’t encounter power loss issues in the future, it’s essential to adopt preventive measures that address potential problems before they escalate. Implementing a routine of preventive maintenance and regular inspections can greatly enhance your vehicle’s reliability.

- Conduct regular inspections: Check wiring, connections, and battery terminals for corrosion or wear.

- Maintain proper fluid levels: Verify all fluids, especially fuel and oil, meet manufacturer specifications.

- Stay updated on software: Regularly update your vehicle’s software to fix bugs that may affect performance.

Frequently Asked Questions

Can I Use a Heat Shrink Kit on Any Vehicle?

Yes, you can use a heat shrink kit on most vehicles, but vehicle compatibility is essential. Make sure the heat shrink tubing you choose matches the wire gauge and insulation type of your vehicle’s electrical system. It’s also important to take into account the operating temperature and environment. Always check the manufacturer’s specifications to guarantee proper application, as using incompatible materials may lead to electrical failures or safety hazards down the line.

How Often Should I Inspect My Vehicle’s Electrical Connections?

You should inspect your vehicle’s electrical connections regularly, ideally every few months or before long trips. Just like a ship needs a steady helm to navigate stormy seas, your vehicle relies on robust connection maintenance to function smoothly. Regular inspections can help catch any potential issues early, preventing costly repairs or dangerous breakdowns. Always prioritize checking for corrosion, loose wires, and wear, ensuring your ride remains reliable and your freedom on the road intact.

What Tools Are Needed Besides a Heat Shrink Kit?

Besides a heat shrink kit, you’ll need wire strippers, multimeter, electrical tape, and a soldering iron for effective troubleshooting techniques. Don’t forget safety precautions—always disconnect the battery before working on electrical systems to prevent shocks. A good set of pliers and a wrench may also come in handy for securing connections. Having these tools on hand will guarantee you’re prepared for resolving any intermittent power loss issues while enjoying your driving freedom.

Is It Safe to Drive With Intermittent Power Loss?

It’s not safe to drive with intermittent power loss. Imagine cruising down the highway, only to feel your engine stutter—a jarring experience that raises serious safety concerns. The driving risks are significant; you could lose control, especially in vital situations. It’s essential to diagnose the issue promptly. Ignoring this problem could lead to more severe consequences, not just for you but for others on the road. Prioritize safety and address the power loss immediately.

How Can I Tell if the Problem Is Electrical or Mechanical?

To determine if the problem’s electrical or mechanical, start with electrical diagnostics. Check for loose connections, blown fuses, or faulty wiring. If the issue persists, inspect mechanical components like the fuel system or engine parts. Pay attention to symptoms—if it’s a sudden loss of power with no warning lights, it’s likely mechanical. However, if you notice electrical fluctuations, it’s probably electrical. Methodically eliminate each possibility to pinpoint the root cause.