Preventive Care to Stop Body Panel Buzz on the Bodywork

To prevent body panel buzz, start by securing all fasteners and mounting points, then isolate vibration sources like brackets and clips. Conduct regular exterior inspections for chips, gaps, and loose seals, logging findings with dates. Use appropriate seals and torque specs, replace worn components on schedule, and apply damping or lubrication where metal-to-metal contact occurs. Finish with a protective coating plan to reduce wear and vibrations. Stay vigilant; more steps await that can keep buzz from returning.

Identifying Common Causes of Body Panel Buzz

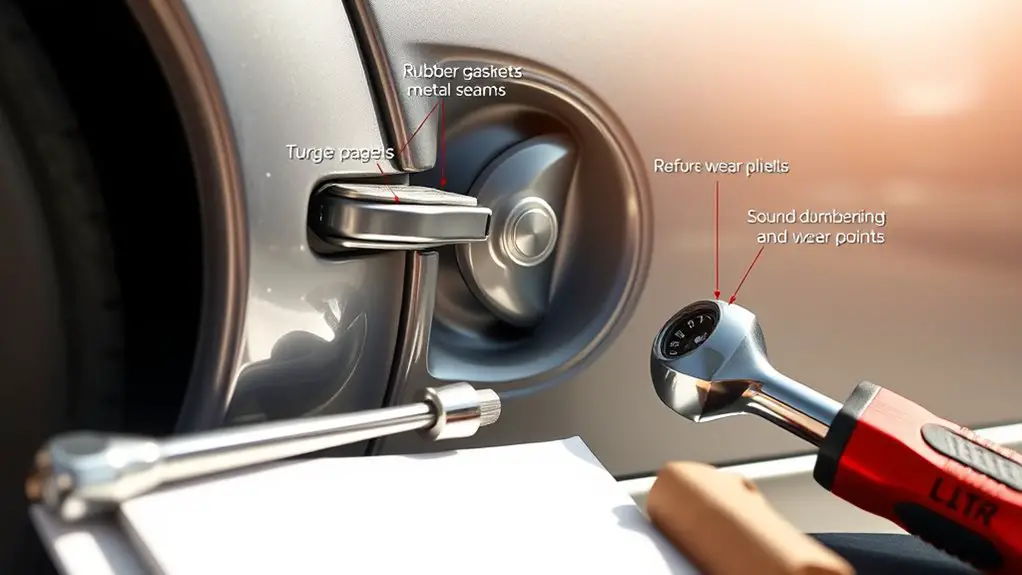

Common causes of body panel buzz fall intoa few predictable categories. You’ll notice panel vibration when panels aren’t securely fastened or when mounting points loosen over time, creating low-frequency rattle that travels behind the surface. Noise sources often originate from part-to-part contact, such as brackets, clips, or stabilizers that vibrate at engine or road frequencies. You’ll also encounter resonance when panels share cavities with vibrating components, turning a slight tremor into a audible buzz. Misaligned gaps amplify the effect, letting air and engine vibrations couple into the sheet metal. Material differences matter too: thinner or inconsistent coatings can flex more easily, amplifying tiny movements into louder tones. Environmental factors like temperature shifts and moisture can alter fit, influencing variability in noise. By tracking these categories—loose hardware, contact points, resonance, alignment, and materials—you establish a precise map for targeted fixes.

Regular Inspection Routines for Exterior Panels

Regular exterior checks establish a baseline for your panels and help you catch issues early. By following a timely inspection cadence, you can spot hidden hazards before they worsen and affect structural integrity. Use a simple, data-driven checklist to track findings and inform maintenance decisions.

Routine Exterior Checks

Routine exterior checks involve quick, systematic inspections of exterior panels to spot damage, wear, or corrosion before it worsens. You’ll build a simple cadence: weekly visual inspections, note any chips, scratches, or loose seals, and track changes over time. This routine maintenance mindset keeps panels pristine and reduces costly surprises. Data shows consistent checks cut repair costs and downtime by providing early warnings. You’ll rely on clear, repeatable steps to stay in control of your bodywork’s health. Embrace a calm, proactive approach to maintenance, so you preserve freedom of expression and trust in your ride.

- Inspect for surface irregularities, rust, and gaps

- Verify fasteners and seals are secure

- Log findings and schedule timely touch-ups and paint protection

Hidden Panel Hazards

Hidden panel hazards can lurk behind seemingly inconspicuous gaps or misaligned trim, making regular exterior inspections essential. You’ll want a simple checklist: secure fasteners, uniform gaps, and consistent sealant wear. Over time, hidden hazards emerge as paint microcracks or corrosion travels, often silent until a panel vibrates at highway speed. Regular palpation of joints helps you detect looseness before noise or leakage begins. Record findings with date stamps and note any changes in panel alignment or creak frequency, then address root causes like mounting stress or frame movement. This approach reduces surprises, protects ballast, and preserves resale value. By staying proactive, you reclaim a sense of control and freedom—knowing you’ve minimized panel vibrations through disciplined, data‑driven checks.

Timely Inspection Cadence

Keeping an eye on exterior panels isn’t a one-off task—it benefits from a steady cadence that catches issues before they become costly. Timely inspection cadence gives you predictable maintenance and reduces surprises. By establishing clear inspection intervals, you can map when sounds, gaps, or rust might appear and act fast. Use maintenance reminders to stay on track, not scramble to recall parts later. Regular checks help you compare current condition with prior data, highlighting trends and wear rates. This data-driven approach supports freedom to plan, budget, and avoid major repairs.

- Set inspection intervals based on exposure, mileage, and climate

- Use reminders for follow-ups and filter out overdue tasks

- Document findings to track improvements or deteriorations over time

Safe Fastener and Seal Maintenance Practices

While regular checks are essential, safe fastener and seal maintenance starts with understanding correct torque specifications, seal types, and replacement intervals to prevent leaks and component failures.

You’ll prioritize fastener types appropriate for each joint, choosing materials with compatible thermal expansion and corrosion resistance. Pair these with seal materials that match fluid compatibility and service temperature. Record torque values, inspection intervals, and seal life estimates to minimize over-tightening, galling, or fatigue.

Table: Visual Guide

| Topic | Action | Outcome |

|---|---|---|

| Fastener types | Select per loading | Reliable clamping |

| Seal materials | Match fluid/ temp | Leak prevention |

| Torque specs | Use proper torque | Consistent preload |

| Replacement intervals | Schedule timely changes | Preventive reliability |

| Documentation | Log readings | Traceable maintenance |

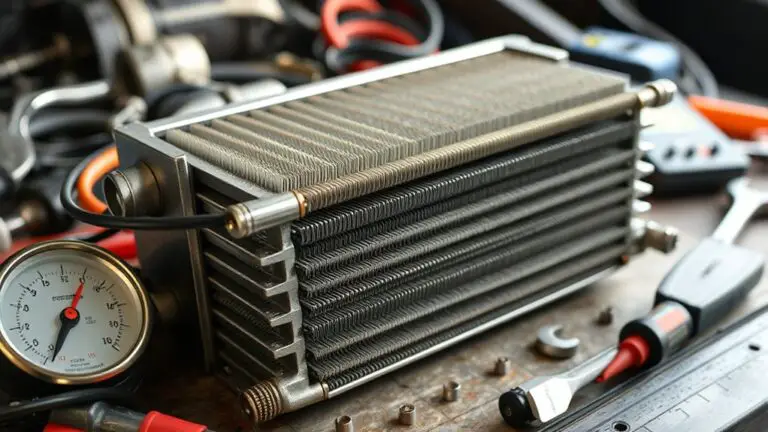

Lubrication and Damping Options for Noise Reduction

Lubrication and damping choices directly impact noise, wear, and long-term reliability after setting proper fastener torque and seal strategies. You’ll select lubrication techniques that reduce metal-to-metal contact and minimize stick-slip, while considering operating temperature, load, and compatibility with materials. Damping materials should be chosen for effective vibration attenuation without deadening response or adding excessive mass. In practice, you’ll balance viscosity, film thickness, and application method to form a stable, durable barrier that shields sheet metal joints from chatter. Combine with targeted dampers or compliant bushings where misalignment or resonance is likely. Test under real-world conditions to verify gains in quietness and endurance, then document service intervals and reapplication needs. Your goal is predictable, repeatable performance that supports a feeling of freedom in use and ownership.

- Use lubrication techniques that suit load, temperature, and substrate.

- Pair with damping materials aligned to expected vibration modes.

- Validate performance through field testing and maintenance records.

Protective Coatings and Paint Care to Prevent Fatigue

Protective coatings and paint care help shield your bodywork from fatigue by reducing micro-damage and preserving finish integrity. A durable finish minimizes wear from environmental exposure and daily use, while best-practice maintenance supports long-term protectant performance. We’ll explore how shielding strategies, consistent care routines, and product choices interact to extend longevity and reduce fatigue risk.

Shielding Against Fatigue

Shielding Against Fatigue: protective coatings and paint care play a key role in extending a bodywork’s lifespan by reducing surface wear, corrosion, and micro-damage that accumulate with use. You’ll benefit from predictable maintenance, fewer touch-ups, and better energy efficiency as wear is slowed. By choosing coatings with proven fatigue resistance, you support fatigue management and energy conservation on the road. Regular inspection and timely reapplication minimize micro-etching that can escalate stress without dramatic costs. Use proper washing, gentle cleaners, and controlled curing to preserve coating integrity. This approach keeps your panels resilient and your workflow efficient, helping you stay ahead of corrosion-driven fatigue while preserving the look you value.

- Inspect and recoat per schedule

- Select high-durability, fatigue-resistant finishes

- Maintain clean surfaces to reduce micro-damage

Durable Finish Practices

Durable Finish Practices: Protective coatings and paint care are essential for preventing fatigue in bodywork. You’ll benefit from selecting durable coatings proven to resist UV degradation and chemical exposure, then applying them with consistent prep and curing. Data show that properly prepped surfaces and controlled bake or cure cycles extend finish longevity by reducing micro-matches and micro-cracks that trap moisture. You should establish a routine: clean, decontaminate, and light-scuff the panel, followed by a high-build primer if needed, then a topcoat with a protective layer. Use appropriate sealants and recoat intervals recommended by manufacturers to sustain gloss and hardness. Track performance, noting any chipping or fading, and adjust techniques to maintain finish longevity and user freedom in maintenance decisions.

Prolonged Protectant Care

Prolonged Protectant Care builds on durable finishes by focusing on how protective coatings resist fatigue over time. You’ll see that proper application and maintenance reduce micro-scratches,UV wear, and chemical breakdown, extending gloss and integrity. This approach emphasizes data-driven schedules, material compatibility, and real-world fatigue resistance, so you can act with confidence. By integrating prolonged detailing and periodic washing into a routine, you minimize buildup that accelerates wear and preserve aesthetic value. You’ll track performance metrics like gloss retention and contaminant resistance to guide reapplication timelines. Embrace a practical, freedom-minded mindset: fewer surprises, more predictable outcomes.

- Use prolonged detailing to extend coating life and measure fatigue resistance over cycles

- Schedule periodic washing to prevent grime-induced abrasion and chemistry damage

- Align reapplication with product data and real-world wear indicators

Scheduling Timely Replacements Before Wear Issues Grow

Scheduling timely replacements before wear issues grow is essential for maintaining effective bodywork. You’ll approach maintenance with a data-driven mindset, tracking wear indicators and aligning replacements to concrete thresholds rather than estimates. By defining objective timelines and criteria, you minimize downtime and maximize longevity. Preventive maintenance isn’t guesswork; it’s a planned sequence driven by measurable signals, inspection intervals, and component-specific life cycles. You’ll monitor performance data, compare it against manufacturer specifications, and schedule substitutions before failure modes appear. Prioritizing timely replacements reduces the risk of cascading damage and costly repairs, preserving panel integrity and overall aesthetics. This approach also supports autonomy: you control upkeep, so you stay ahead rather than react. Documented intervals and clear wear indicators provide a reliable roadmap for decisions. Keep communication open with your team or service partner, ensuring everyone understands the timing, rationale, and anticipated benefits of each planned replacement.

Signs That Buzz Is Returning and What to Do Next

If you’ve been tracking wear indicators to prevent failures, you might notice buzz returning as components loosen or loosened tolerances reemerge. Recognize this as a warning signal, not a surprise. You’ll want to verify with objective checks: compare current sounds to baseline, note frequency shifts, and track accessory looseness. Use buzz detection techniques to isolate the source, then map it to likely culprits such as mounting brackets, fasteners, or panel edges. Pair this with sound frequency analysis to distinguish harmonic buzz from brief transient chatter. If the pattern persists, schedule targeted inspection before a panel begins to flex or fail. Document changes so you can detect gradual progression over time. Take corrective steps promptly—retorque fasteners, reseal joints, or replace worn components.

Monitor baseline shifts with buzz detection; act before panels fail.

- Monitor baseline shifts with buzz detection techniques

- Apply sound frequency analysis to identify sources

- Act on persistent patterns before failures occur

Frequently Asked Questions

Can Engine Vibrations Cause Panel Buzz Beyond Exterior Panels?

Yes, engine vibrations can cause panel buzz beyond exterior panels. You’ll see it if engine mounts wear or motor mounts loosen, transferring vibration into the chassis. Effective vibration dampening relies on solid mounts and proper isolation. You should inspect mounts and inspect related fasteners, then upgrade or replace as needed. With good vibration dampening, you reduce buzz, preserve ride feel, and keep interior panels quiet while you pursue freedom in driving.

Do Aftermarket Parts Affect Panel Noise Differently Than OEM?

Yes, aftermarket parts can affect panel noise differently than OEM, depending on fit, material, and tolerances. You’ll see variability in vibration paths, so your noise reduction may improve or worsen. Look for aftermarket materials designed for reduced resonance and tighter tolerances, and verify claims with data or test results. You’ll want precise installation, plus isolation bushings or dampers where needed, to maintain consistent interior acoustics and preserve your freedom to enjoy driving without buzz.

How Do Temperature Changes Influence Buzz Frequency Over Time?

Temperature fluctuations can shift buzz frequency as panels expand and contract, nudging sound frequencies over time. You’ll see frequency drift when ambient temps rise or fall, especially with uneven panel stiffness or fasteners. Track changes with simple measurements: note buzz onset times, record temps, and compare where it quiets. Over months, gradual shifts reflect material aging and mounting load. You’ll optimize by tightening, adding isolation, and selecting stiffer trims to stabilize frequencies.

Can DIY Fixes Worsen Panel Fatigue or Cause New Buzzes?

Yes, DIY repairs can worsen panel fatigue or create new buzzes if you skip proper measurement, use improper fasteners, or over-torture panels. You’ll reduce noise and improve vibration management only when you assess bolts, clips, and bonding, test with controlled loads, and document changes. Focus on noise reduction techniques, guarantee even torque, and don’t neglect fatigue-prone areas. When in doubt, seek professional guidance to avoid compromising structural integrity.

Are There Warranty Implications for Noise-Related Panel Issues?

Yes, there can be warranty implications for noise-related panel issues. If the noise stems from a manufacturing defect or a covered component, it may fall under warranty coverage. Document your noise complaints with dates, locations, and demonstrations, and have the dealer inspect. Keep records of repairs and modifications. If a repair is deemed non-covered, you may still pursue goodwill adjustments or coverage under consumer protection, depending on your market.