Preventive Checks to Stop Starter Motor Failure in Their Tracks

To stop starter motor failure in its tracks, focus on preventive checks. Regularly maintain your battery by cleaning terminals and testing voltage levels. Inspect electrical connections for tightness and corrosion, and routinely test the ignition switch for proper functionality. Monitor the starter relay to guarantee it connects the battery effectively. Keeping your starter motor clean and scheduling professional inspections will enhance reliability. There’s more to explore in optimizing your vehicle’s performance.

Understanding the Starter Motor’s Role in Your Vehicle

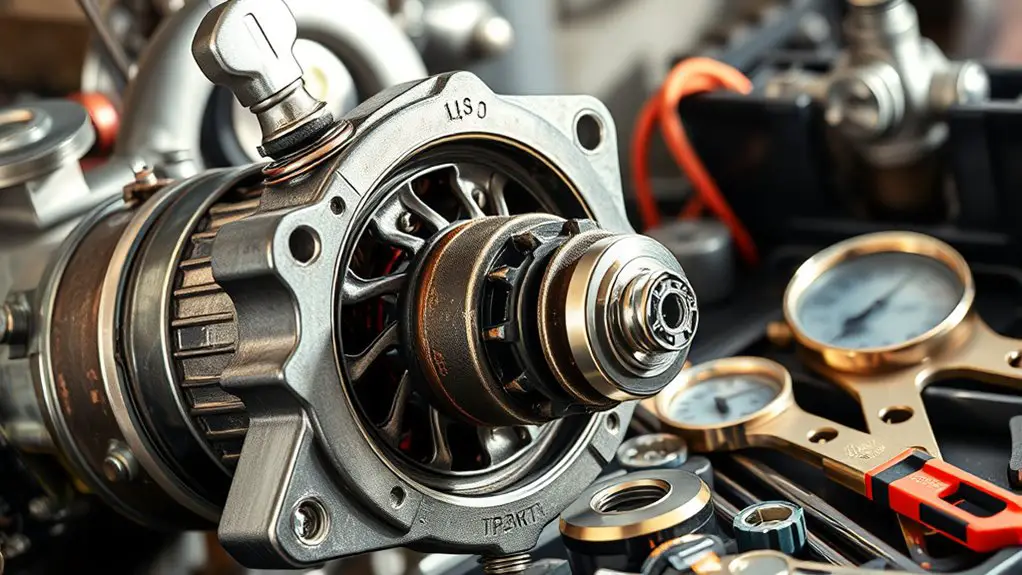

Although you might not think about it often, the starter motor plays an important role in your vehicle’s operation. It’s responsible for initiating the engine’s function, ensuring that your journey begins smoothly. The primary starter motor components include the armature, solenoid, and pinion gear, all working in unison to engage the engine.

When you turn the ignition key, the solenoid activates, pushing the pinion gear into the flywheel, which allows the armature to spin. This action generates the necessary torque to start the engine. If any of these components fail, you’ll face difficulties, leading to potential breakdowns. Understanding the starter motor function is vital for maintaining your vehicle’s reliability and freedom on the road. By recognizing signs of wear or malfunction, you can take preventive measures, ensuring your starter motor remains in optimal condition and your travels remain uninterrupted.

Regular Battery Maintenance

To guarantee ideal starter motor performance, regular battery maintenance is essential. Start by cleaning battery terminals to prevent corrosion, which can hinder electrical flow. Additionally, implement a routine for voltage testing to confirm your battery’s health and avoid unexpected failures.

Battery Terminal Cleaning

Maintaining clean battery terminals is essential for ensuring the ideal performance of your vehicle’s starter motor. Battery corrosion can hinder electrical flow, leading to starting issues and potential failure. To prevent this, regularly inspect your terminals for any signs of corrosion buildup. If you spot any, disconnect the battery, and use a mixture of baking soda and water to clean the terminals thoroughly. A wire brush can help remove stubborn deposits, but be gentle to avoid damaging the terminals. After cleaning, apply a protective coating, such as petroleum jelly or a commercial terminal protector, to prevent future corrosion. This simple maintenance step can greatly enhance your starter motor’s reliability and prolong the life of your battery.

Voltage Testing Routine

Since a well-functioning starter motor relies on sufficient voltage from the battery, implementing a regular voltage testing routine is crucial for ideal performance. Start by using reliable testing equipment, such as a digital multimeter, to measure the battery voltage. Ideally, you want readings above 12.6 volts when the engine is off. Monitor for any voltage fluctuations that could indicate issues with the battery or connections. Conduct these tests monthly, especially before long trips or during extreme weather conditions. If you notice voltages dropping considerably or fluctuating, it could signal a failing battery, necessitating immediate attention. Regular voltage testing not only extends battery life but also guarantees your starter motor operates smoothly, giving you the freedom to drive without worry.

Inspecting Electrical Connections

To guarantee your starter motor functions reliably, you need to inspect the electrical connections regularly. Start by checking the battery connections for corrosion or looseness, then move on to the wiring harness for any signs of wear or damage. Finally, testing the ground points is critical, as poor grounding can lead to performance issues.

Check Battery Connections

One essential step in preventing starter motor failure is ensuring that battery connections are secure and free from corrosion. Check the terminals for any built-up grime or oxidation, as these can hinder connection integrity. A strong connection is crucial for peak battery health, ensuring that your starter motor receives the necessary power. Use a wire brush to clean any corrosion and tighten the connections if they’re loose. It’s also wise to inspect the battery cables for any signs of wear or damage. Regular maintenance of these electrical connections not only enhances performance but also extends the lifespan of your starter motor. By prioritizing this check, you empower yourself to maintain your vehicle’s reliability and efficiency.

Inspect Wiring Harness

After securing battery connections, the next critical step involves inspecting the wiring harness. Start by examining the wiring insulation for any cracks, fraying, or discoloration. These signs can indicate potential harness wear that may lead to electrical failures. Confirm all connectors are tight and free from corrosion, as loose or corroded connections can disrupt the flow of electricity to the starter motor. Pay special attention to areas where the harness bends or rubs against other components, as these spots are prone to wear. If you notice any damage, it’s essential to replace the affected sections immediately. By diligently inspecting the wiring harness, you can prevent unexpected starter motor failures and maintain your vehicle’s reliability.

Test Ground Points

When inspecting electrical connections, testing ground points is essential for guaranteeing the starter motor functions properly. Ground continuity issues can lead to significant starting problems. Using a multimeter for testing can help you identify these faults quickly.

- Verify all ground connections are clean and secure.

- Measure resistance between the ground point and the battery negative terminal.

- Guarantee connections are free from corrosion or damage.

- Check for loose or frayed wires that may disrupt the circuit.

Testing the Ignition Switch

Since the ignition switch plays a crucial role in starting your vehicle, testing it should be among your first steps when diagnosing starter motor issues. To start, verify the battery is charged and connected properly. Then, use a multimeter to check for voltage at the ignition switch. Set the multimeter to the appropriate setting, and probe the switch terminals while turning the key to the ‘on’ position. You should see a voltage reading if the switch is functioning correctly.

Next, consider performing a continuity test. Disconnect the ignition switch and connect the multimeter leads to the terminals. When you toggle the switch, the multimeter should indicate continuity. If it doesn’t, the ignition switch may be faulty.

Employing these testing methods can quickly identify ignition switch issues, helping you prevent starter motor failure and keep your vehicle running smoothly.

Monitoring Starter Relay Functionality

To guarantee reliable operation of your starter motor, monitoring the functionality of the starter relay is essential. The starter relay acts as a switch that connects the battery to the starter motor. If it malfunctions, you’ll face starting issues. Regular checks can prevent unexpected breakdowns and costly repairs.

- Understand different relay types to choose the right one for your vehicle.

- Test your relay periodically to verify it’s functioning properly.

- Replace any faulty relay immediately to maintain engine performance.

- Keep an eye on the relay’s wiring connections for corrosion or damage.

Keeping the Starter Motor Clean

Keeping your starter motor clean is vital for peak performance, as dirt and grime can hinder its functionality. Regular attention to starter cleanliness guarantees that the motor operates smoothly, reducing the risk of failure. Here’s a quick overview of effective debris removal techniques:

| Method | Benefits | Frequency |

|---|---|---|

| Visual Inspection | Identifies buildup quickly | Monthly |

| Compressed Air | Removes loose debris | Bi-monthly |

| Cleaning Solution | Breaks down stubborn grime | As needed |

| Soft Brush Cleaning | Prevents damage to components | Monthly |

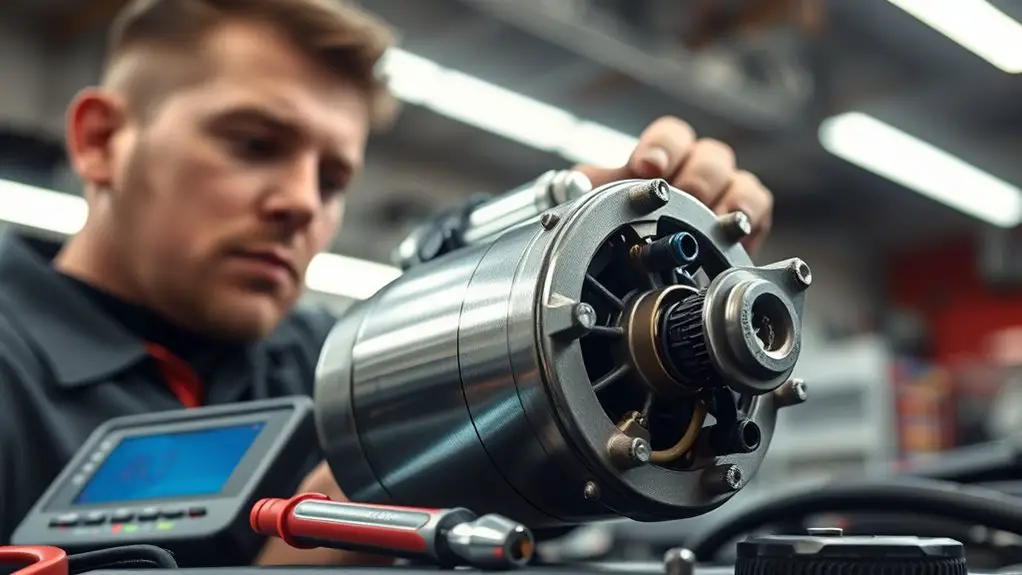

Scheduling Routine Professional Inspections

Scheduling routine professional inspections is essential for maintaining your starter motor’s reliability and performance. Regular checks can help identify potential issues before they escalate into costly repairs or leave you stranded. By adhering to a routine scheduling plan, you guarantee that your starter motor remains in peak condition.

- Early Detection: Catch minor problems before they become major failures.

- Expertise: Benefit from the specialized knowledge of trained technicians.

- Longevity: Extend the life of your starter motor through preventive care.

- Peace of Mind: Enjoy confidence in your vehicle’s performance and reliability.

Incorporating these inspections into your vehicle maintenance routine allows you to stay ahead of potential failures. Don’t wait until you experience issues; proactive care is the key to freedom on the road. Make professional inspections a priority to keep your starter motor functioning smoothly and efficiently.

Frequently Asked Questions

How Do I Know if My Starter Motor Is Failing?

If your starter motor’s failing, you might notice that about 25% of cars experience starting issues at least once a year. Look for starter symptoms like clicking sounds, slow cranking, or the engine not turning over. It’s wise to run diagnostic tests to pinpoint the problem. If you’re experiencing these signs, don’t ignore them—addressing a failing starter can save you time and hassle, ensuring your freedom on the road remains intact.

Can Extreme Temperatures Affect Starter Motor Performance?

Yes, temperature extremes can markedly affect your starter motor’s performance. In cold weather, grease can thicken, making it harder for the motor to turn over. Conversely, extreme heat can lead to overheating, damaging electrical components and leading to performance issues. Regular checks in varying temperatures can help you identify potential problems early. Keeping your battery and starter motor in good condition is essential for maintaining reliable performance in all weather conditions.

What Are Common Signs of a Weak Battery?

Common signs of a weak battery include slow engine cranking, dim headlights, and electrical issues like flickering dashboard lights. If you notice any of these symptoms, it’s essential to prioritize battery maintenance to extend its lifespan. Regularly checking connections and ensuring the battery is fully charged can prevent unexpected failures. Don’t ignore these indicators; addressing them promptly can save you from inconvenient breakdowns and enhance your vehicle’s overall performance.

How Often Should I Replace My Starter Motor?

You should consider replacing your starter motor every 100,000 miles or so, depending on the vehicle and usage. The starter lifespan can vary; some may last longer, while others might fail sooner. Regular inspection during maintenance can help identify issues early. If you notice signs like a slow cranking engine or unusual noises, it might be time for a replacement, even if you haven’t hit that interval yet. Stay proactive for freedom on the road!

Is It Safe to Jump-Start a Car With a Faulty Starter?

Jump-starting a car with a faulty starter isn’t safe. While it might temporarily get you going, a faulty starter can lead to electrical issues or even damage your vehicle’s battery. Furthermore, jump start safety is compromised if the starter’s condition is unknown. It’s best to diagnose and fix the faulty starter before attempting to jump-start. You’ll avoid potential hazards and guarantee your vehicle runs smoothly and reliably.