Tool Guide: Using a Mechanic’s Stethoscope to Diagnose Loss of Power

To diagnose power loss using a mechanic’s stethoscope, start by identifying common symptoms like sluggish acceleration and unusual noises. Place the probe on suspected components to amplify sound, ensuring you listen for anomalies. Use proper listening techniques to differentiate between normal and failing sounds, such as high-pitched whines or deep rumbles. Combining this with additional diagnostic tools will enhance your assessment. There’s much more to uncover about effective power loss diagnosis and the signals your vehicle provides.

Understanding the Mechanic’s Stethoscope

A mechanic’s stethoscope is an essential tool for diagnosing mechanical issues in vehicles. Understanding the mechanic’s stethoscope basics will enhance your ability to pinpoint problems effectively. This tool utilizes sound amplification techniques to capture and magnify noises from various engine components.

When you place the stethoscope’s probe against parts like the engine block, transmission, or wheel bearings, it enables you to hear subtle sounds that could indicate wear or failure. For instance, a tapping noise might suggest a loose component, while a grinding sound could signify something more serious.

Using the stethoscope not only aids in diagnosing current issues but also helps you prevent future failures by recognizing early warning signs. Familiarizing yourself with the different sounds can empower you to take action before minor issues escalate, ensuring your vehicle remains reliable and freeing you from unexpected breakdowns.

Identifying Common Symptoms of Power Loss

When you notice a decrease in your vehicle’s performance, it’s vital to identify the common symptoms of power loss to address potential issues promptly. Start with a symptom checklist to help pinpoint the problem. Common indicators include sluggish acceleration, unusual engine noises, and a drop in fuel efficiency. You might also experience vibrations or shaking while driving, which can signal deeper mechanical issues.

Pay attention to warning lights on your dashboard, as these can indicate malfunctions in the engine or transmission systems. Additionally, note any changes in exhaust emissions, such as excessive smoke or a strong smell of fuel. By recognizing these symptoms early, you can take action before the problem escalates, ensuring your vehicle maintains ideal performance and freedom on the road. Identifying power loss symptoms is vital for effective troubleshooting and repair.

How to Use a Mechanic’s Stethoscope

To effectively diagnose mechanical issues, knowing how to use a mechanic’s stethoscope can be invaluable. Start by ensuring proper stethoscope maintenance; check for any damage or wear on the diaphragm and tubing. Once you’re ready, identify the area of concern on your vehicle. Place the stethoscope’s probe directly against the component you suspect, such as the engine or transmission.

Listen carefully to the sounds produced. Each component emits unique sound frequencies, which can indicate different problems. A consistent tapping might suggest a loose part, while grinding sounds could signal wear or damage. Adjust the volume on your stethoscope if necessary to capture subtle variations in sound. Remember, using this tool effectively requires practice; familiarizing yourself with normal sounds will help you distinguish anomalies. With time, you’ll gain the confidence to diagnose issues swiftly, giving you the freedom to maintain your vehicle efficiently.

Listening Techniques for Effective Diagnosis

To diagnose effectively, you need to master proper stethoscope placement, as this guarantees you capture the most relevant sounds. Identifying unusual sounds and analyzing their patterns can reveal critical information about mechanical issues. With practice, you’ll enhance your listening skills, leading to more accurate diagnostics.

Proper Stethoscope Placement

Proper placement of a mechanic’s stethoscope is essential for accurate diagnosis, as even a slight misalignment can lead to missed or misleading sounds. Start by ensuring the stethoscope’s diaphragm is firmly against the component you’re examining. For engine diagnostics, focus on areas like the cylinder head or timing belt cover, as these spots yield significant sound amplification. Adjust the stethoscope positioning to explore different angles, and don’t hesitate to move it around to capture varying sounds. Maintain a steady hand to minimize external noise interference. Remember, the objective is to isolate specific sounds, so be patient and attentive. Each component may emit unique frequencies, and proper stethoscope placement is key to deciphering these vital auditory signals.

Identifying Unusual Sounds

While diagnosing mechanical issues, recognizing unusual sounds is essential for pinpointing problems effectively. When you use a mechanic’s stethoscope, pay close attention to any unusual vibrations or noises that deviate from the norm. These sounds often signal underlying engine anomalies, such as worn bearings or failing components. Listen for knocking, rattling, or hissing, as they can indicate specific issues like a loose part or vacuum leak. Position the stethoscope at various points on the engine to isolate the source of the sound, allowing you to differentiate between normal operational noise and problematic vibrations. By honing your listening skills, you’ll enhance your diagnostic capabilities and address issues before they escalate, ultimately preserving the engine’s performance.

Analyzing Sound Patterns

Analyzing sound patterns is essential for effective diagnosis when using a mechanic’s stethoscope. Start by focusing on sound frequency; different issues produce distinct frequencies. For instance, a high-pitched whine might indicate a bearing failure, while a low rumble could suggest engine troubles. Pay attention to noise characteristics, such as volume and rhythm. Consistent clicking can signal a problem in the valve train, while irregular sounds might point to misfiring. Utilize the stethoscope to isolate sounds from various components, moving it close to the source for clarity. With practice, you’ll learn to differentiate between normal and abnormal sounds. This keen listening will empower you to diagnose issues more accurately and efficiently, ultimately restoring your vehicle’s performance.

Interpreting the Sounds: What They Mean

When you listen to engine sounds through a mechanic’s stethoscope, identifying unusual noises is essential for diagnosis. You’ll need to distinguish between normal engine sounds and those that indicate potential issues with components. Understanding these auditory cues can help you pinpoint specific problems effectively.

Identifying Unusual Noises

Identifying unusual noises in a vehicle can be essential for diagnosing potential issues, and a mechanic’s stethoscope is an invaluable tool in this process. By listening for sound frequency variations, you can pinpoint the source of the problem. Unusual vibrations often accompany these sounds, indicating wear or malfunction in components like bearings or belts.

| Noise Type | Possible Issue |

|---|---|

| Clicking | Loose or damaged parts |

| Hissing | Exhaust leak or vacuum issue |

| Grinding | Worn-out gears or brakes |

| Whining | Power steering or transmission |

| Knocking | Engine or suspension issue |

Using this table, you can effectively correlate what you hear with potential mechanical issues, enabling you to take action sooner.

Distinguishing Engine Sounds

To effectively distinguish engine sounds, you need to listen closely for specific characteristics that indicate the condition of various components. Pay attention to engine noise variations; different components produce unique sounds at specific sound frequencies. For instance, a high-pitched whine might signal a problem with the alternator or belt, while a low rumble could indicate exhaust issues. Knocking or tapping sounds often suggest internal wear or misalignment. By utilizing a mechanic’s stethoscope, you can isolate these frequencies, allowing you to pinpoint the source of the sound more accurately. Remember, understanding these nuances can empower you to diagnose potential issues before they escalate, giving you greater control over your vehicle’s performance and longevity.

Diagnosing Component Issues

Understanding the sounds your engine makes is key to diagnosing component issues effectively. By using a mechanic’s stethoscope, you can pinpoint areas of concern, especially concerning component wear. Listen closely to the sound frequency; for instance, a high-pitched whine may indicate a failing bearing, while a deep rumble could suggest problems with the crankshaft. Each sound carries information about the engine’s health. If you notice inconsistencies, such as a sudden change in frequency, it’s a signal to investigate further. Regularly evaluating these sounds can help you catch issues before they escalate, allowing you to maintain freedom from costly repairs and guarantee your engine runs smoothly. Trust your ears; they’re your first line of defense in diagnosis.

Additional Tools to Complement Your Diagnosis

While a mechanic’s stethoscope is an invaluable tool for pinpointing engine issues, several additional instruments can enhance your diagnostic capabilities. Diagnostic software is essential for accessing error codes and monitoring real-time data from your vehicle’s onboard computer. By connecting your vehicle to a scanner, you can quickly identify underlying issues that may not be audible through a stethoscope alone.

Mechanical gauges, such as pressure and temperature gauges, provide critical insights into engine performance. Monitoring oil pressure, coolant temperature, and fuel pressure can reveal discrepancies that lead to power loss. These gauges allow you to visualize performance metrics, making it easier to isolate problems.

Together, these tools create a thorough diagnostic approach. By integrating the auditory feedback from your stethoscope with the data from diagnostic software and mechanical gauges, you can develop a clearer understanding of your vehicle’s condition and effectively tackle performance issues.

When to Seek Professional Help

Even if you’ve equipped yourself with the right tools and knowledge, there are times when seeking professional help becomes necessary. If you notice signs of urgency—such as unusual noises, significant power loss, or warning lights on your dashboard—it’s vital to consult a professional mechanic. These indicators often signify underlying issues that could lead to further damage if left unaddressed.

You should also seek help when you’ve exhausted your diagnostic efforts without a clear resolution. Sometimes, problems require specialized expertise or equipment that’s beyond your reach. An experienced technician can provide a thorough assessment and may identify problems you might overlook.

Don’t hesitate to reach out when your vehicle’s performance deteriorates, as timely intervention can save you from costly repairs down the line. Remember, your safety and the longevity of your vehicle depend on knowing when to consult with a professional.

Frequently Asked Questions

Can a Mechanic’s Stethoscope Help With Non-Engine Related Issues?

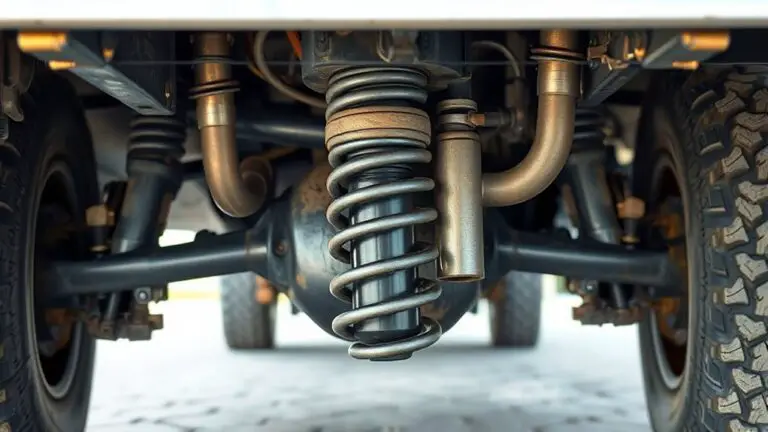

Yes, a mechanic’s stethoscope can definitely help with non-engine related issues. When you’re dealing with brake noise, placing the stethoscope near the brake components can pinpoint where the sound originates. Similarly, if you suspect suspension issues, it can assist in identifying abnormal sounds from struts or shocks. This tool empowers you to diagnose problems more accurately, ensuring you can address any concerns with precision and confidence.

How Do I Maintain My Mechanic’s Stethoscope?

To maintain your mechanic’s stethoscope, start with regular cleaning techniques. Wipe the earpieces and chest piece with disinfectant wipes after each use to prevent contamination. Store it in a protective case to avoid damage and keep it free from dust. Avoid extreme temperatures and moisture during storage, as these can affect its performance. Following these simple steps guarantees your stethoscope remains reliable and effective for diagnosing various issues.

Are There Any Alternatives to a Mechanic’s Stethoscope?

Consider your engine as a symphony, where every sound tells a story. If you’re looking for alternatives to a mechanic’s stethoscope, electronic listening devices can amplify engine sounds, revealing hidden issues. Vibration analysis tools also provide insights by detecting irregular vibrations, pinpointing potential problems. These options offer a different approach to diagnostics, giving you the freedom to choose the tool that best suits your needs in uncovering the truth behind your vehicle’s performance.

What Is the Cost Range for a Mechanic’s Stethoscope?

A mechanic’s stethoscope typically costs between $10 to $50, depending on the brand and features. For budget options, you can find basic models that perform well without breaking the bank. When considering a cost comparison, higher-end stethoscopes may offer additional features like adjustable sensitivity. It’s important to balance your needs with your budget, ensuring you get a reliable tool without overspending. With the right choice, you’ll diagnose issues efficiently and effectively.

Can I Use a Mechanic’s Stethoscope on All Vehicle Types?

You can generally use a mechanic’s stethoscope on various vehicle types, but there are some limitations. It’s crucial to take into account vehicle compatibility, as some systems may have noise levels or access points that make it challenging to get accurate readings. For example, electric vehicles might not produce sounds that a traditional stethoscope can detect. Always verify you’re familiar with the specific components of the vehicle you’re diagnosing to maximize your stethoscope’s effectiveness.