Top Causes of Corroded Terminals and Quick Fixes

Moisture and humidity can accelerate terminal corrosion, so guarantee proper sealing and coatings. Poor connections due to dirt or corrosion lead to performance issues; regular inspections and tightening are key. Watch out for chemical exposure from harsh substances, and use protective barriers when possible. Vibration and movement can loosen connections, so secure terminals with brackets and use vibration dampening solutions. Finally, age and wear increase susceptibility, making routine maintenance essential. Discover more effective prevention strategies as you go further.

Moisture and Humidity

Moisture and humidity can greatly contribute to the corrosion of terminals, especially in environments where water exposure is frequent. Water accumulation on terminals creates an ideal environment for corrosion to thrive. Environmental factors such as temperature fluctuations can exacerbate this issue, as they often lead to condensation on surfaces. When moisture interacts with metal components, it forms electrolytic solutions that accelerate the corrosion process.

To mitigate corrosion risks, it’s essential to address water accumulation promptly. You should consider using protective coatings or sealing techniques that can shield terminals from moisture. Regular inspections can help you identify signs of corrosion early, allowing for timely intervention. Additionally, ensuring proper drainage in areas where terminals are installed can help reduce the chances of water pooling. By understanding these influences, you can take proactive measures to protect your terminals and maintain their efficiency.

Poor Connections

Poor connections can lead to significant performance issues in electrical systems, often resulting from corrosion, dirt, or improper installation. You may encounter bad wiring and loose fittings that compromise the integrity of your connections. These issues can cause intermittent failures, increased resistance, and eventually, complete system failure.

To address poor connections, start by inspecting your terminals and wiring. Identify any signs of corrosion or dirt buildup and clean them thoroughly with a suitable contact cleaner. Check for loose fittings—tighten any that are not secure. If you spot any damaged wires, replace them to guarantee a reliable connection.

Regular maintenance can prevent future issues, so consider performing routine checks to verify everything’s in prime shape. By staying proactive, you can maintain peak performance and extend the lifespan of your electrical systems, allowing you the freedom to operate without disruption.

Chemical Exposure

When terminals are exposed to harsh chemicals, they can corrode rapidly, leading to compromised connections and unreliable performance. Chemical reactions between the terminals and substances like acids, bases, or solvents can initiate corrosion, making it essential to address this issue promptly. Here are some effective corrosion prevention strategies:

- Use Protective Coatings: Apply a suitable coating to terminals to create a barrier against chemical exposure.

- Regular Inspection: Frequently check terminals for any signs of chemical contact and corrosion. Early detection is key.

- Environment Management: Keep terminals in a controlled environment, minimizing exposure to harmful substances.

Vibration and Movement

Although vibrations and movement are often unavoidable in many applications, they can greatly contribute to terminal wear and degradation. Over time, these forces can loosen connections, leading to increased resistance and potential failure. To combat this, proper terminal maintenance is essential. Regularly checking and tightening connections will help maintain integrity and performance.

Implementing vibration dampening solutions can also greatly reduce the impact of movement on terminals. Consider using rubber mounts or pads to absorb vibrations, preventing them from transferring to critical components. Additionally, securing terminals in place with brackets or adhesive solutions can minimize displacement and wear.

Age and Wear

Vibrations and movement can exacerbate the effects of age and wear on terminals, leading to increased susceptibility to corrosion and connection failures. As terminals age, their lifespan diminishes, making regular maintenance practices essential. Here are three key considerations to prolong terminal life:

- Routine Inspections: Regularly check terminals for signs of wear or corrosion. Early detection can prevent further damage.

- Proper Cleaning: Use a suitable cleaning solution to remove corrosion and dirt. This helps maintain peak conductivity and prevents deterioration.

- Secure Connections: Verify terminals are tightly connected. Loose connections can cause friction, leading to increased wear and eventual failure.

Frequently Asked Questions

How Can I Prevent Corrosion on Battery Terminals?

To prevent corrosion on battery terminals, you should implement preventive measures like regularly cleaning the terminals with a mixture of baking soda and water. Make sure you apply a protective grease or anti-corrosion spray after cleaning. Regular terminal maintenance is key; check for tight connections and inspect for any signs of wear or damage. Additionally, you might want to keep the battery and terminals dry, as moisture accelerates corrosion considerably.

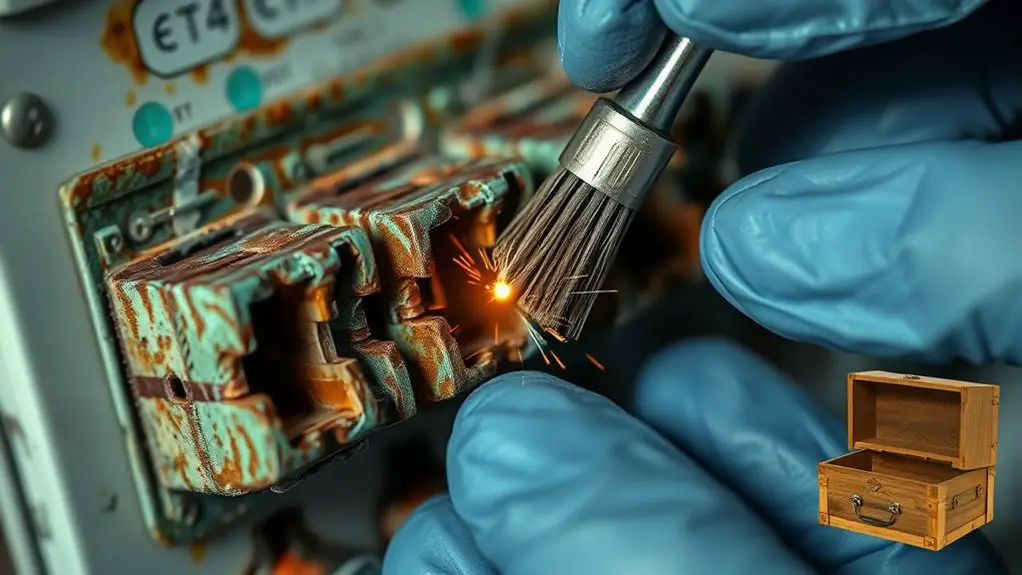

What Tools Are Needed for Terminal Cleaning?

For terminal cleaning, you’ll need a few essential tools: a wire brush or battery terminal cleaner, baking soda, water, and protective gloves. These items help effectively remove corrosion and promote corrosion prevention. When cleaning, mix the baking soda and water to create a paste, apply it to the terminals, and scrub with the wire brush. Always wear gloves for safety, ensuring your hands stay protected during the process.

Can Corrosion Affect Electronic Device Performance?

Oh, sure, corrosion’s just a little party crasher in your electronic device’s performance! When corrosion sets in, it wreaks havoc on electronic reliability, leading to poor connections and erratic behavior. You might find your gadgets acting like temperamental divas, refusing to cooperate. In short, corrosion effects can greatly diminish the effectiveness of your devices, making them less reliable and potentially shortening their lifespan. So, let’s keep those terminals clean and happy!

How Often Should I Check My Terminals?

You should check your terminals during regular battery maintenance, ideally every 1-3 months. This terminal inspection helps catch corrosion early, preventing performance issues. If you notice any buildup, clean it promptly to guarantee the best connection. Keeping a consistent schedule not only extends battery life but also enhances the reliability of your devices. By staying proactive, you’ll enjoy uninterrupted freedom in your electronic use, avoiding unexpected failures.

Is Corrosion Repairable or Do I Need Replacements?

Yes, corrosion is often repairable, and you don’t necessarily need replacements. You can clean corroded terminals using a mixture of baking soda and water, then applying a protective coating afterward to enhance terminal longevity. However, if corrosion is extensive and compromises the terminal’s integrity, replacement might be your best option. Always consider repair options first, as maintaining terminals can save you money and extend the life of your electrical connections.