Top Causes of Water Pump Failure and Long-Term Fixes

You’ll reduce downtime and extend pump life by targeting seven core failure drivers: bearing and impeller wear, debris ingress, air leaks and cavitation, overheating, electrical/control faults, poor system design, and inadequate maintenance. Inspect bearings, align impellers, and monitor lubrication and temperature. Filter inlets to prevent particulates, seal lines against air intrusion, and verify NPSH margins to curb cavitation. Ascertain proper cooling, robust electrical controls, and disciplined maintenance with contamination controls. If you continue, you’ll uncover long‑term fixes that compound reliability.

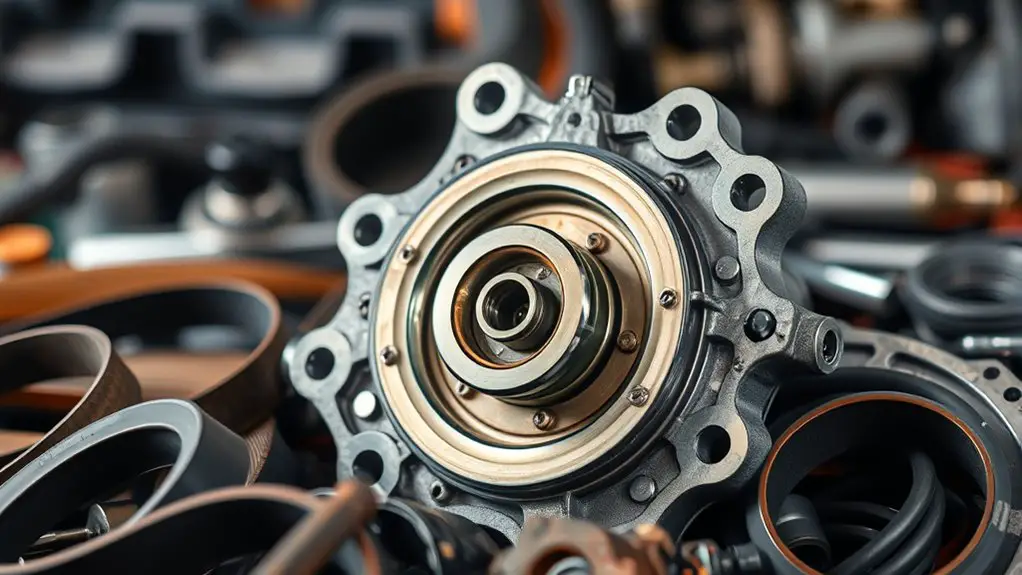

Wear and Tear on Bearings and Impellers

Wear and tear on bearings and impellers is a common root of pump failure, as friction, load, and fluid conditions gradually degrade rotating components. You’ll inspect bearing lubrication integrity and check for lubricant contamination, filter erosion, and scheduled intervals that match duty cycles. Misalignment or improper mounting stresses the bearing race and shaft, accelerating wear and inducing vibration signals you can measure with a handheld tachometer or vibration meter. Pay attention to bearing preload, clearances, and hydraulic loading, since mismatches increase heat and degrade lubricants. You’ll verify impeller alignment to guarantee the flow path remains coaxial, minimizing imbalance that raises shaft bending and seal wear. Monitor temperature rise across the bearing housing, noting deviations from baseline that indicate lubrication breakdown or lubrication starvation. When you restore lubrication quality and correct alignment, you extend service life, reduce resonant effects, and preserve hydraulic efficiency without introducing unnecessary complexity. Maintain clear records to guide proactive maintenance planning and avoid cascading failures.

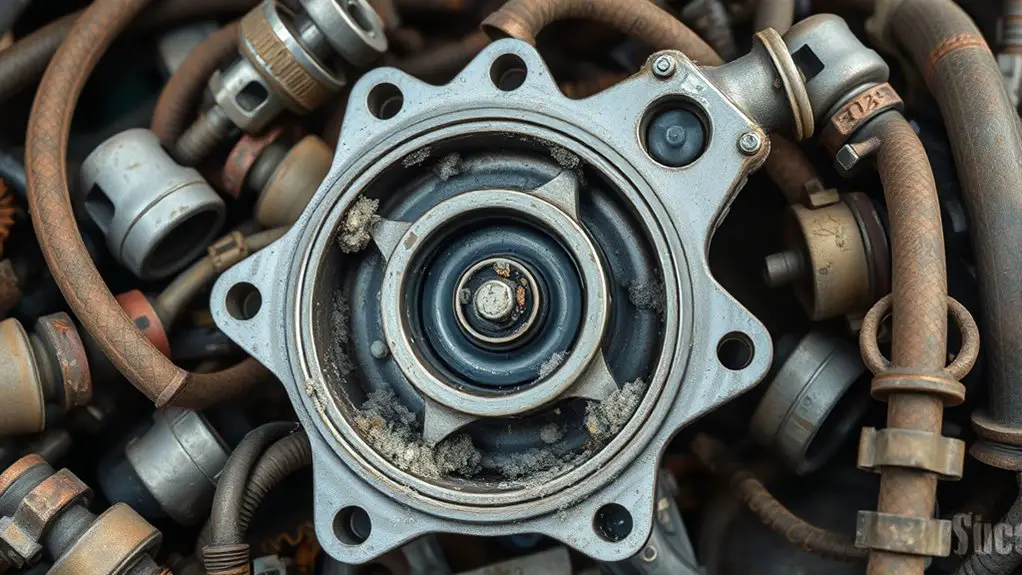

Sediment and Debris Ingress

Sediment and debris ingress introduces particulates that can obstruct flow, abrade internal surfaces, and accelerate wear in pumps. You should assess debris influx sources and the resulting sediment accumulation to gauge filtration needs and maintenance intervals. This checks the balance between intake cleanliness, system pressures, and the risk of particulate-induced failures.

Debris Influx Effects

Debris influx, including sediment and debris ingress, can disrupt pump performance by clogging intakes, reducing flow, and accelerating wear on impellers and seals. You’ll notice fluctuating pressure, uneven discharge, and higher energy consumption as passages constrict. The root cause is uncontrolled particulate entry; the remedy hinges on proactive debris management and robust exclusion methods. Implement filtration systems at entry points to capture oversized matter before it reaches the pump, and schedule routine inspection of strainers and screens. Combine mechanical barriers with best practices for intake placement to minimize turbulence and suction draw of debris. Monitor differential pressure across filtration elements to detect clogging early. Maintain clean, accessible housings and document flow trends. These steps preserve efficiency, extend component life, and sustain reliable operation under variable conditions.

Sediment Accumulation Risks

Sediment accumulation poses a distinct risk to pumps by gradually reducing flow areas and altering hydraulic characteristics, which can elevate suction losses and induce cavitation under certain operating conditions. You’ll see performance degrade as particulates build a bottleneck, forcing the system to work harder and shortening component life. To mitigate, implement sediment filtration upstream and monitor debris levels during each maintenance window. A disciplined maintenance schedule keeps impellers, intakes, and strainers clear, preserving flow paths and preventing unexpected outages. Efficiency hinges on timely cleanouts and filtration replacement, not reactive fixes. Table below highlights key factors and actions for rapid reference.

| Factor | Risk | Action |

|---|---|---|

| Sediment load | Increased suction loss | Install sediment filtration; schedule frequent inspections |

| Maintenance cadence | Downtime risk | Establish a maintenance schedule; track filter life |

| Debris ingress | Cavitation potential | Pre-screen intakes; clean channels regularly |

Air Leaks and Cavitation

Air leaks and cavitation are common culprits in pump inefficiency and failure. You’ll assess suction lines, seals, and fittings for traceable gaps, since even minor air intrusion reduces effective head and raises motor load. Air pressure differentials at the intake create unstable flow, causing pressure pulsations that degrade performance and promote cavitation effects in the impeller eye. When cavitation occurs, vapor pockets collapse violently, eroding surfaces and increasing vibration, noise, and wear rates downstream. You’ll monitor pump curves to detect shifts in operational point that indicate cavitation risk, then verify NPSH availability and air-free suction. Corrective actions include tightening or replacing gaskets, purging trapped air, ensuring proper orientation, and maintaining fluid viscosity within design specs. Do not overlook system losses from minor leaks, as they compound inefficiency over time. Implement preventive checks and timely resealing to sustain reliability, reduce maintenance frequency, and protect long-term pump life.

Overheating and Insufficient Cooling

Overheating signals elevated bearing and seal stress, increasing the risk of pump failure if heat buildup isn’t controlled. You should verify that the cooling system maintains adequate flow and temperature, since insufficient cooling directly compounds heat buildup risks. Begin with targeted cooling-system checks and heat-management measures to quantify and mitigate heat-related failure modes.

Heat Buildup Risks

Heat buildup in a well-functioning water pump can occur when the motor and bearings dissipate more energy than the cooling system can remove, leading to rising temperatures that degrade performance and shorten life. You’ll assess heat pathways and identify where losses outpace removal. Key drivers include motor current, bearing friction, and environmental load. Focus on heat dissipation methods that move energy away from hot surfaces efficiently, such as conduction through housings, convection to ambient air, and targeted cooling fins. Evaluate insulation quality to prevent unnecessary internal heat retention, then balance insulation with accessible maintenance. Maintain precise tolerances, verify bearing lubrication, and monitor temperature trends to detect early anomalies. Prioritize design choices and operating practices that sustain stable temperatures and prolong pump reliability.

Cooling System Checks

Cooling system checks focus on diagnosing insufficient cooling and overheating symptoms by tracing heat paths from the motor to the environment and verifying that all cooling interfaces function as specified. You assess coolant flow, identify bottlenecks, and confirm that heat exchangers, seals, and radiators meet design targets. Pinpointing where temperature rises occur lets you distinguish external airflow limitations from internal blockages. You perform systematic measurements of coolant temperatures, flow rates, and pressure margins to guarantee consistent heat removal under load. Pay close attention to coolant levels and pressure checks, verifying that fill levels align with manufacturer guidance and that pressure readings remain within recommended ranges under operating conditions. Document deviations, isolate causes, and implement targeted fixes to restore reliable cooling and protect the pump from thermal stress.

Electrical Failures and Control Issues

Electrical failures and control issues can halt a pump’s operation even when mechanical components appear sound. You’ll focus on how control systems and electrical troubleshooting determine reliability, not just raw power. When faults arise, you’ll systematically verify connections, sensors, and logic sequences to isolate the root cause.

1) Inspect wiring integrity and protection devices, confirming bends, corrosion, and correct fuse sizing.

2) Validate control signals, relay contacts, and interlocks, ensuring proper sequencing and safety overrides.

3) Diagnose sensor feedback and motor drive parameters, checking for drift, scaling errors, and fault codes.

A disciplined approach reduces downtime and extends life. You’ll document observed anomalies, correlate them with operating conditions, and apply targeted fixes rather than broad modifications. Emphasize redundancy where feasible, but avoid overengineering. Embrace clear naming, modular testing, and traceable results. Your goal is robust operation through precise electrical troubleshooting and solid control-system practices, maintaining freedom to adjust parameters while preserving safety, efficiency, and controllability of the pumping system.

Poor System Design and Improper Sizing

Poor system design and improper sizing undermine reliability from the outset, making pumps operate outside safe or efficient boundaries. You must recognize how misjudged head, flow, and duty cycle distort performance, shorten life, and raise energy costs. A disciplined approach centers on system evaluation and precise pump specifications, aligning pump curves with actual demand and downstream losses. When design gaps appear, you’ll see excessive vibrations, cavitation risk, and unstable pressures that propagate faults through controls and instrumentation. To avoid this, map system requirements, verify NPSH availability, and select dynamic pumps with appropriate margins. Below is a concise reference to keep you on track.

| Criterion | Parameter | Action |

|---|---|---|

| System evaluation | Duty cycle, flow, head | Validate with site data and simulations |

| Pump specifications | Model, efficiency, NPSH | Match to verified requirements |

| Installation considerations | Piping, valves | Minimize losses, validate proper sizing |

| Reliability targets | MTBF, vibration | Specify tolerances and monitoring |

Inadequate Maintenance and Contamination Control

Inadequate maintenance and contamination control directly undermine the reliability gains achieved through proper design and sizing. You’ll lose performance as neglect allows wear, clogging, and unexpected shutdowns to escalate. Focused discipline reduces risk, extends life, and preserves efficiency. Below, a concise framework follows.

- Schedule and perform routine inspections to catch wear, corrosion, and alignment issues before they cascade into failures.

- Identify contamination sources, implement filtration and sealing strategies, and verify cleanliness of fluids and intermediate components.

- Establish a disciplined maintenance cadence, track metrics, and update procedures to reflect changing operating conditions and component wear.

Why it matters: neglect accelerates degradation, muda-free operation becomes improbable, and energy costs rise. By aligning inspections, contamination controls, and maintenance rigor, you reclaim reliability gains and sustain performance. You retain freedom to operate with confidence, knowing your pump system remains within design intent and lifecycle expectations.

Frequently Asked Questions

How Long Is a Typical Bearing Lifespan Under Varying Loads?

A typical bearing lifespan under varying loads ranges from thousands to tens of thousands of hours, depending on load intensity and duty cycle. You’ll find that higher bearing load accelerates wear, reducing life, while variable or alternating loads can induce fatigue sooner. Lifespan factors include lubrication quality, material hardness, misalignment, and temperature. You’ll want to quantify load spectra, monitor vibration, and maintain lubrication to optimize bearing life and sustain performance under demanding conditions.

Can Pump Failure Be Predicted Before Warning Signs Appear?

Yes, you can predict pump failure before warning signs appear. By applying pump diagnostics and predictive maintenance, you detect subtle deviations in vibration, temperature, and flow patterns early. You’ll quantify risk, schedule interventions, and minimize downtime. Continuous monitoring enables trend analysis, threshold tuning, and proactive parts replacement. Embrace data-driven decisions, document findings, and refine models as operating conditions shift. This approach grants you freedom from reactive fixes and optimizes system reliability.

What Maintenance Interval Balances Cost and Reliability Best?

For balancing cost and reliability, schedule preventive maintenance every 6 to 12 months, tailored to duty cycle and operating conditions. You’ll optimize uptime by aligning inspections, lubricant changes, and seal checks with a formal cost analysis, weighing mean time between failures against downtime costs. This interval minimizes total ownership cost while preserving performance. Reassess after unusual vibration, noise, or efficiency drop. Maintain records to refine the interval as usage patterns evolve, ensuring ongoing reliability.

Do Energy Efficiency Upgrades Reduce Long-Term Pump Wear?

Yes, energy efficiency upgrades can reduce long-term pump wear. By improving motor efficiency and reducing unnecessary load, you lower thermal stress, vibration, and cycling fatigue, which preserves pump longevity. You’ll see energy savings from lower power draw, plus fewer wear-related failures over time. Guarantee proper sizing, high-efficiency motors, and optimized controls. Regular monitoring confirms benefits, and you’ll maintain performance while extending service life, aligning with both cost and reliability goals.

How Do You Verify Proper System Sizing After Installation?

You verify proper system sizing after installation by performing a thorough system evaluation and targeted performance testing. You compare actual flow, head, and pressure against the design specifications, adjust controls, and document deviations. You simulate peak demand and validate pump curves, motor efficiency, and vibration levels. You verify temperature rise, energy use, and runtime to confirm margins. You iterate until results meet commissioning criteria, ensuring reliable operation and measurable, reproducible performance improvements.