Troubleshooting Manual Transmission Won’t Go Into Gear in a Manual Sedan

If your manual sedan won’t go into gear, start by checking the clutch system. Confirm the clutch pedal fully engages and releases to allow smooth gear changes. Inspect the transmission fluid; it should be bright red and free of debris. Examine the shift linkage for wear or misalignment. Look for hydraulic issues with the clutch master and slave cylinders. Finally, assess the gear synchronizers for wear. There’s more to explore about each component to narrow down the problem.

Understanding the Clutch System

When you press the clutch pedal, you’re engaging a critical component of the manual transmission system that allows for smooth gear changes. The clutch engagement is essential for disconnecting the engine’s power from the wheels, enabling you to shift gears without grinding. When you fully depress the clutch pedal, the pressure plate releases tension on the clutch disc, allowing it to spin freely. This action permits gear selection while the engine is still running.

If you experience difficulty shifting gears, it could indicate issues with the clutch system, such as worn components or hydraulic problems. You might notice a spongy or unresponsive clutch pedal, which could signal low fluid levels or air in the hydraulic lines. Maintaining the best clutch engagement guarantees that you retain control and freedom in your driving experience. Regular checks can help you identify issues before they escalate, preserving the efficiency of your manual transmission.

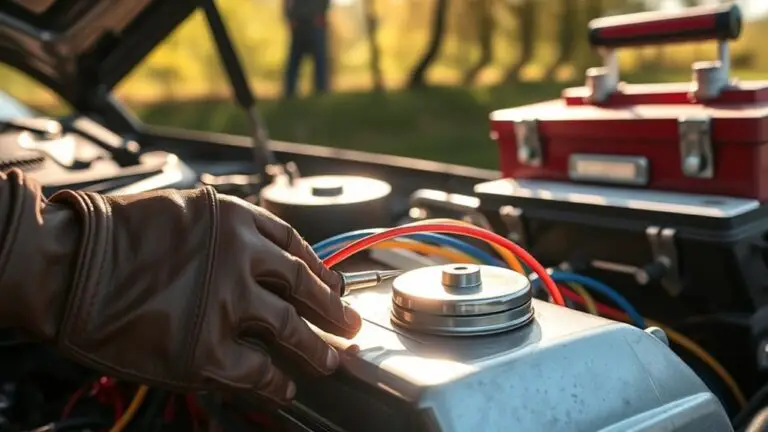

Checking the Transmission Fluid

Proper clutch function relies not only on the components within the clutch system but also on the overall health of the transmission fluid. To guarantee your manual transmission operates smoothly, start by checking the transmission fluid. Begin with the engine off and the vehicle on a level surface. Locate the dipstick or fill plug, typically found on the transmission body. Remove it and inspect the fluid’s color and consistency. Healthy transmission fluid is usually a bright red and free of debris; if it appears dark or smells burnt, it needs replacing.

Next, check the fluid level. Insert the dipstick back, remove it again, and observe the markings. The fluid level should be within the recommended range. If it’s low, add the appropriate transmission fluid until it reaches the correct level. Regularly monitoring your transmission fluid can prevent many issues, guaranteeing your driving freedom remains uninterrupted.

Inspecting the Shift Linkage

Inspecting the shift linkage is essential for guaranteeing smooth gear engagement and overall transmission performance. Start by checking for any visible signs of linkage wear, such as frayed cables or bent rods. These can hinder your ability to shift effectively. Next, verify that the shift linkage adjustments are correctly set. Misalignment can lead to difficulties in engaging gears.

If you notice excessive play in the linkage, it’s a sign that wear has occurred, and you may need to replace worn components. Also, confirm that all connections are secure and free of debris. Lubricate pivot points as necessary to reduce friction and improve responsiveness.

Lastly, if everything appears intact but the issue persists, consider further diagnostics. A well-maintained shift linkage system contributes considerably to your driving freedom and enjoyment. Regular inspections can prevent costly repairs down the line.

Diagnosing Clutch Master and Slave Cylinders

As you troubleshoot clutch issues, diagnosing the clutch master and slave cylinders is essential, since these components play an important role in your vehicle’s ability to engage and disengage the clutch smoothly. Start by checking the clutch pedal adjustment; if it’s too high or low, it may prevent proper fluid movement. Next, inspect for any signs of a hydraulic fluid leak around the master and slave cylinders. A leak can greatly reduce pressure, resulting in difficulty shifting gears.

To test the master cylinder, press the clutch pedal and observe its response. If it feels spongy or sinks to the floor, it might be failing. For the slave cylinder, look for fluid around it and listen for any unusual noises. If you notice any abnormalities, it’s time to replace the affected component. Addressing these issues promptly can restore your driving freedom and guarantee a smooth shifting experience.

Identifying Gear Synchronizer Issues

After confirming that the clutch master and slave cylinders are functioning correctly, attention should shift to the gear synchronizers. These components play an essential role in facilitating smooth gear engagement. If you notice grinding noises or difficulty shifting into gear, it’s likely that your synchronizers are worn or damaged.

To identify issues, start by inspecting the transmission fluid for debris or discoloration, which can indicate internal wear. Next, observe the behavior during gear shifts; if the engagement feels notchy or obstructed, this points to synchronizer failure.

In some cases, you may need to perform a synchronizer replacement to restore proper function. This process involves disassembling the transmission, so confirm you have the necessary tools and expertise. Addressing gear synchronizer issues promptly not only enhances driving freedom but also prevents further damage to your transmission system.

Frequently Asked Questions

Can I Drive My Car if It Won’t Go Into Gear?

No, you can’t drive your car if it won’t go into gear. Attempting to do so poses significant safety concerns, both for you and others on the road. In emergency situations, the inability to control your vehicle can lead to serious accidents. It’s essential to address the issue immediately. You should consider having a professional diagnose the problem to guarantee your freedom on the road is restored safely and effectively.

What Are Common Signs of a Worn-Out Clutch?

Did you know that nearly 70% of manual transmission issues stem from clutch problems? If you’re noticing a soft or spongy clutch pedal, it might indicate wear. A slipping clutch, where your engine revs but your speed doesn’t match, is another sign. Additionally, difficulty shifting gears or unusual noises when engaging the clutch can signal impending failure. Addressing these symptoms early can help you maintain your driving freedom and avoid costly repairs.

How Often Should I Check My Transmission Fluid?

You should check your transmission fluid at least every 30,000 miles or during routine maintenance. Regular transmission inspection is essential for ensuring peak performance and longevity. If you notice any signs of fluid leaks or changes in shifting behavior, it’s wise to inspect more frequently. Proper fluid maintenance helps prevent costly repairs and keeps your vehicle running smoothly, giving you the freedom to enjoy the drive without worry.

Are There Specific Tools Needed for Manual Transmission Troubleshooting?

Imagine a skilled knight, armed with the right tools, ready to conquer the challenges of a manual transmission. For your endeavor, you’ll need essential diagnostic tools like a pressure gauge to measure fluid pressure and possibly a multimeter for electrical checks. Wrenches and screwdrivers will aid in accessing components. With these instruments, you can dissect the intricacies of your transmission, seeking the freedom that comes from understanding and resolving its issues.

Can Weather Conditions Affect My Manual Transmission Performance?

Yes, weather conditions can affect your manual transmission performance. In cold temperatures, transmission fluid thickens, which can hinder shifting and responsiveness. Additionally, high humidity can lead to moisture accumulation in the transmission, potentially causing rust or fluid contamination. These factors can create resistance within the system, making it harder for you to engage gears smoothly. Regular maintenance and monitoring of fluid quality can mitigate these weather-related issues, ensuring your freedom on the road.