When a Rebuild Is Necessary for Differential

When a rebuild is necessary for your differential, look for signs like grinding noises, fluid leaks, or excessive vibrations while driving. These indicate internal wear or damage that can compromise performance. Overloading and neglecting maintenance can exacerbate issues. If you notice instability or pulling while turning, it’s a strong signal that components may be misaligned or failing. Understanding these signs and causes can help you take timely action. Discover more about maintaining your differential efficiently.

Signs of Differential Wear and Tear

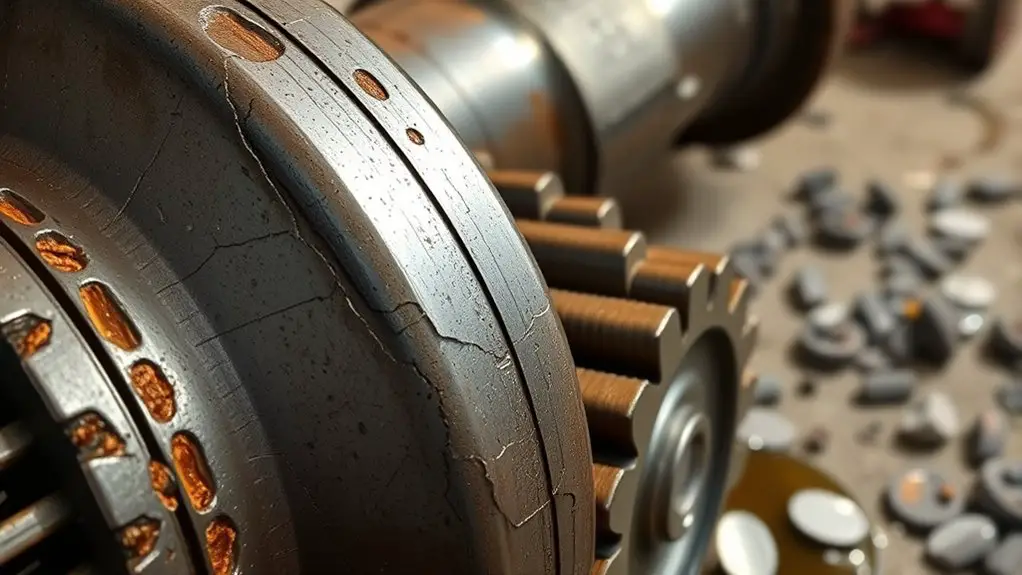

Differential wear and tear can manifest in various ways, signaling potential issues that need attention. One of the most noticeable signs is differential noise. If you hear grinding, whining, or clunking sounds during operation, it’s an indicator that components may be failing or misaligned. These noises often suggest that the gears or bearings are experiencing excessive friction, which can lead to further damage if ignored.

Fluid leaks are another critical sign of differential wear. If you spot oil pooling under your vehicle or notice a decrease in the differential fluid level, it’s essential to investigate. Leaks can compromise lubrication, leading to overheating and accelerated wear on internal components.

Common Causes of Differential Damage

When operating a vehicle, understanding the common causes of differential damage can help you prevent costly repairs. Differential failure often stems from various factors that contribute to excessive wear. Here are four key causes to keep in mind:

- Insufficient Lubrication: Low or contaminated fluid can lead to inadequate lubrication, increasing friction and wear.

- Overloading: Exceeding the vehicle’s load capacity puts excessive stress on the differential components, accelerating wear and potential failure.

- Improper Alignment: Misalignment can cause uneven wear on gears and bearings, leading to premature differential failure.

- Neglecting Maintenance: Failing to perform regular inspections and fluid changes can result in unnoticed wear and eventual breakdown.

The Importance of Regular Differential Maintenance

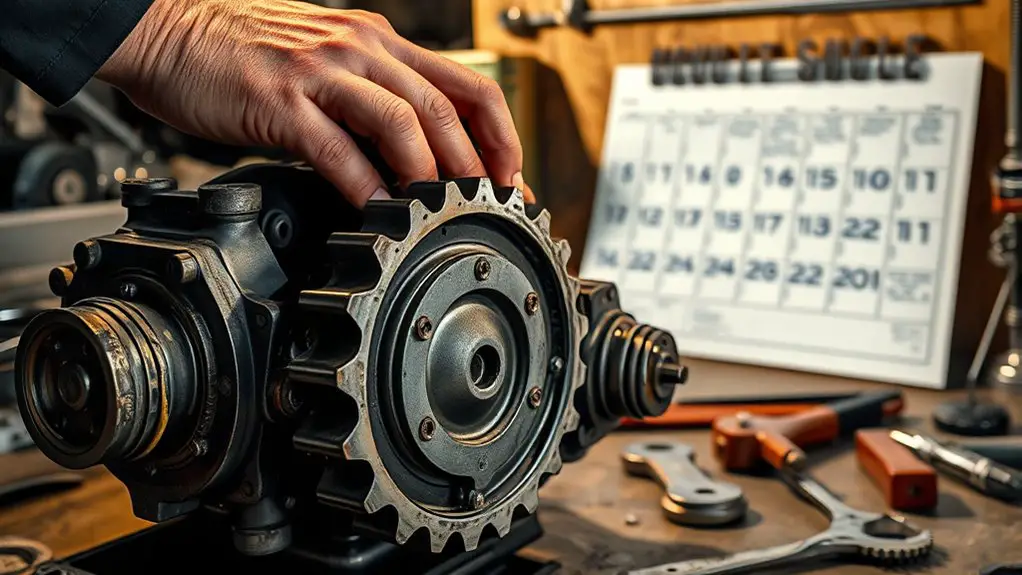

Regular maintenance is essential to ensuring your vehicle’s differential operates efficiently and lasts longer. Adhering to a strict maintenance schedule allows you to monitor and maintain ideal differential lubrication, which is critical for reducing friction and wear. Over time, the lubricant can degrade, leading to increased heat and potential damage. By routinely checking the differential fluid levels and replacing it as recommended, you minimize the risk of costly repairs down the line.

Incorporating regular inspections also enables you to identify any early signs of wear or damage, ensuring that your differential remains in peak condition. You gain peace of mind knowing you’re taking proactive steps to protect your vehicle’s performance. Whether you’re traversing city streets or off-road trails, ensuring your differential is well-maintained empowers you to drive with confidence, knowing you’re maximizing your vehicle’s potential. Prioritize your differential maintenance to enjoy the freedom of the open road without worry.

Symptoms Indicating a Need for Rebuild

Although your vehicle may seem to be operating smoothly, several symptoms can indicate that your differential requires rebuilding. Ignoring these signs can lead to more severe issues down the line, compromising your freedom on the road.

- Differential Noises: Unusual sounds, such as grinding or whining, often suggest internal wear or damage.

- Fluid Leaks: If you notice any fluid pooling under your vehicle, it might point to a failing seal or gasket, leading to insufficient lubrication.

- Vibration: Excessive vibrations while driving, especially during turns, can indicate misalignment or worn components within the differential.

- Handling Issues: If your vehicle feels unstable or pulls to one side while driving, it may signal differential problems affecting traction and control.

Stay vigilant for these symptoms to guarantee your vehicle remains reliable and ready for your adventures.

Steps Involved in a Differential Rebuild

Before diving into a differential rebuild, it’s essential to understand the systematic steps involved in the process to guarantee the best results. First, gather your tool requirements, including a torque wrench, socket set, and a dial indicator. Next, safely lift the vehicle and remove the differential cover to access the internals. Once exposed, inspect components for wear or damage, documenting findings.

Now, drain the fluid and remove the old gears, paying attention to the shim placements for reassembly. As you proceed with the rebuild process, clean all components thoroughly and replace worn parts. Install new bearings and gears, confirming proper alignment and torque specifications are met. Finally, reinstall the differential cover, refill with fresh fluid, and perform a test drive to check for functionality. Following these steps methodically guarantees your differential operates smoothly and efficiently, granting you the freedom to enjoy your vehicle without concerns.

Frequently Asked Questions

How Much Does a Differential Rebuild Typically Cost?

A differential rebuild typically costs between $800 and $2,500, depending on your vehicle and the complexity of the issue. If you’re experiencing differential symptoms like whining noises or uneven tire wear, addressing them promptly can save you from more extensive repairs later. The rebuild benefits include improved performance and extended lifespan of your differential, ensuring you maintain the freedom and reliability you need on the road.

How Long Does a Differential Rebuild Take?

A differential rebuild typically takes anywhere from a few hours to a couple of days, depending on the specific differential symptoms you’ve noticed and the complexity of the rebuild process. If you’re facing issues like whining noises or uneven tire wear, these can extend repair time. Technicians need to thoroughly inspect and replace worn components, ensuring everything’s functioning efficiently. So, it’s best to plan for some downtime while they get your differential back in shape.

Can I Perform a Differential Rebuild Myself?

Yes, you can perform a differential rebuild yourself, but it requires a solid understanding of differential maintenance and rebuild techniques. You’ll need specialized tools and a detailed service manual for your specific vehicle. Take your time to study the disassembly and reassembly processes carefully. If you’re mechanically inclined and patient, it can be a rewarding project, giving you the freedom to customize and enhance your vehicle’s performance in the process.

What Tools Are Needed for a Differential Rebuild?

For a differential rebuild, you’ll need specific differential tools to guarantee precision throughout the rebuild process. Essential tools include a torque wrench, socket set, pry bars, and a dial indicator for measuring gear backlash. You might also require a bearing puller and a seal installer. Having a clean workspace and a good repair manual can make the process smoother, giving you the freedom to tackle the rebuild confidently and efficiently.

Is a Differential Rebuild Covered Under Warranty?

A differential rebuild isn’t always covered under warranty, especially if the issues stem from wear and tear or lack of maintenance. Picture a finely tuned machine, each part working in harmony; neglect can disrupt that balance. If the differential’s problems are rooted in manufacturing defects, you might find warranty coverage applicable. Always check your warranty details, as they can vary, leaving you to navigate potential costs and guarantee your vehicle’s freedom on the road.