Why the Blower Resistor Causes Temperature Uneven Across Vents and How to Fix It

The blower resistor controls each fan speed, and when it’s failing, airflow to vents becomes uneven, making some spots cooler or hotter than others. A weak or intermittent resistor can’t deliver consistent current to the blower motor, so higher speeds may still push air through certain ducts while others lag. To fix it, inspect for heat damage or corrosion, test speeds, and replace the resistor pack if needed, ensuring proper wiring. You’ll uncover more steps and tips as you proceed.

Understanding the Role of the Blower Resistor in Your HVAC System

A blower resistor controls the current to the blower motor, shaping how fast the fan runs and, consequently, the airflow and temperature distribution inside the HVAC system. You’ll understand that this component modulates speed via discrete resistance steps, aligning motor torque with demand. In practice, the blower resistor directly influences the HVAC function by altering air volume without changing heater output. When you select higher speeds, you enable greater duct flow, reducing temperature stratification and shortening warm or cold spots. Conversely, low-speed operation minimizes noise and throttles flow, which can intensify unevenness if other factors are present. Diagnostics focus on continuity, coil integrity, and connector condition, since a degraded resistor increases current draw, alters duty cycles, and risks overheating. With proper replacement or cleaning, you restore predictable performance, maintain energy efficiency, and preserve occupant comfort. You gain reliable control over climate delivery while keeping system operation aligned with your freedom of movement and preferences.

What Causes Uneven Airflow Across Vents

Uneven airflow across vents results from a combination of system design, component performance, and installation factors that disrupt uniform distribution. You’ll see how small variances amplify through the ductwork, creating pockets of low and high velocity that feel like hot or cold spots. Key drivers include airflow imbalance, duct sizing, and connector integrity, which determine how much air actually reaches each vent. Poorly sealed plenum paths or restrictive filters can compound the effect, while fan speed and motor wear shift the balance over time. Obstructions in the vent path, such as debris or partial blockages, force air to redirect and lose pressure. Installation quirks—like improper register placement or inadequate return paths—can bias flow away from certain rooms. Addressing these factors requires a methodical check of routing, sealing, and vent condition to regain tolerance and uniform comfort. Maintaining clear, open vents is essential for consistent performance and freedom in your climate control.

Uneven airflow stems from design, installation, and component performance disrupting uniform distribution.

- airflow imbalance

- vent obstruction

- duct sizing and sealing

- return path adequacy

Diagnosing a Faulty Blower Resistor Without Specialized Tools

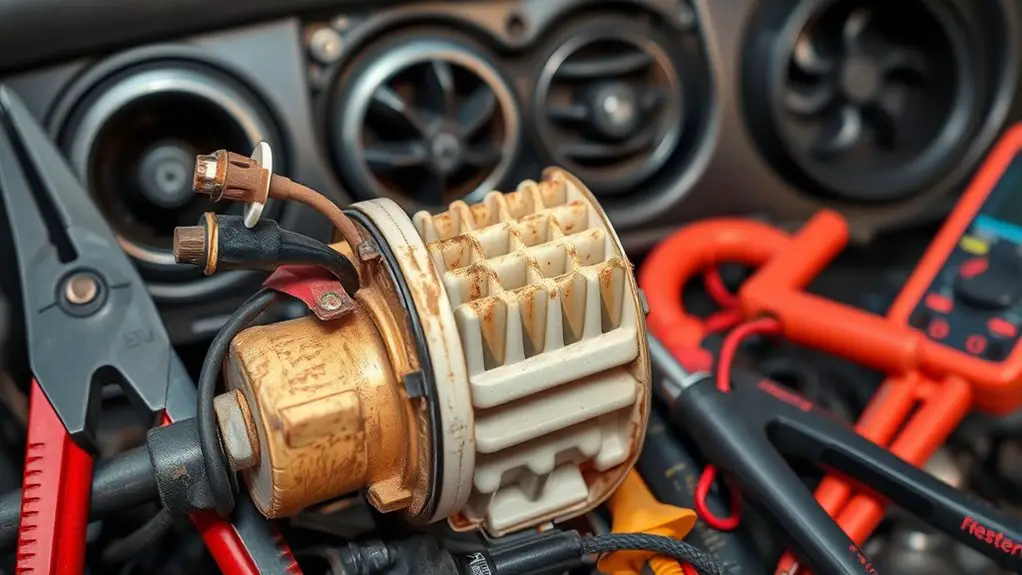

Diagnosing a Faulty Blower Resistor Without Specialized Tools picks up from how airflow can vary across vents, but now we focus on a component-level issue you can assess without advanced equipment. You’ll inspect the blower resistor assembly’s accessibility and junctions for signs of heat damage, corrosion, or loose connectors. Start by verifying that the blower motor speeds respond predictably to seating of the control dial or climate settings, noting any abrupt changes or stalls at mid-range. With the system off, examine the resistor’s wiring for frayed insulation or darkened, blistered surfaces that indicate overheating. Resistance changes often manifest as uneven blower performance across speeds, so compare perceived airflow while the unit cycles through high, medium, and low settings, listening for intermittent hums or clicks. Use basic airflow diagnostics by feeling for consistent intake through the heater core pickup and ensuring no clogging in the duct paths. If abnormalities persist, targeted component testing may be warranted.

Symptoms That Point to a Resistor Problem Vs Other Issues

When should you suspect a resistor problem rather than another fault? You notice consistent uneven airflow despite setting the same fan speed, and you hear no abnormal noises from the blower. This points to a resistor fault rather than a motor issue. If airflow is strong at some speeds but weak or absent at others, the culprit is often the blower resistor assembly rather than ducting. Look for intermittent operation or complete loss of a single speed step, which aligns with resistor failure. Temperature readings that don’t follow input commands, or a mismatch between commanded fan speed and actual vent temperature, also indicate a resistor problem rather than a heat exchanger or sensor fault. Recurrent, localized electrical resistive heating can foreshadow failure and should be considered when diagnosing airflow issues.

Inconsistent airflow and a missing or weak single speed often point to a blower resistor failure.

- Inconsistent velocity across speeds suggests resistor failure

- Sudden loss of a single speed with normal other speeds

- Vent temperature lag or mismatch relative to control input

- Recurrent heating within the resistor assembly signals imminent failure

Safe Steps to Replace or Repair the Blower Resistor

If you’re replacing or repairing the blower resistor, start by disconnecting power at the source and verifying zero voltage with a multimeter to prevent shock or shorts. Locate the blower location on your vehicle or appliance, then remove the cover to access the resistor pack. Identify the resistor types present—carbon film, metal oxide, or a brushless unit—as wiring and terminals vary. Document wire colors and connector orientation before detaching any harness, and label fasteners for accurate reassembly. Inspect the circuit board or blower motor connector for corrosion or lifted pads; clean with isopropyl alcohol if needed. When installing, make certain of proper seating and torque on mounting screws to avoid vibration. Replace any damaged connectors or damaged insulation, and verify inline fuses or relays are intact. Reconnect harnesses in the original orientation, restore power, and check for smooth operation at multiple fan speeds without audible arcing or intermittent contacts.

Post-Repair Testing and Tips for Preventing Recurrence

Post-repair testing should start with a controlled power-up to verify the blower runs smoothly across all speeds, listening for any arcing, buzzing, or intermittent contacts. You’ll validate that the airflow remains consistent and that no new vibrations or abnormal noise appear as you cycle through speeds. Document readings from a simple airflow monitor to establish a baseline for post repair maintenance. If any irregularity shows, halt tests and recheck connections, resistors, and the hub to prevent recurrence.

- Verify even air velocity across vents with a basic airflow meter during mid-range and high-speed settings

- Record voltage and current at each speed to detect drift or load inconsistencies

- Inspect wiring, spade connectors, and the resistor pack for signs of overheating

- Schedule short, repeatability tests over several days to guarantee lasting reliability and stable airflow monitoring

Frequently Asked Questions

Can Resistor Failures Affect Cabin Temperature if Only One Vent Is Hot or Cold?

Yes, resistor failures can affect cabin temperature even if only one vent is hot or cold. A malfunctioning blower resistor may create uneven current to the heater core or blend door, causing uneven airflow and temperature distribution. You’ll notice resistor malfunction symptoms like one vent delivering markedly different temps. This is a classic uneven temperature causes issue, and diagnosing the blower pack and control circuitry is essential for precise, reliable climate control.

Do Dashboard Indicators Reliably Diagnose Resistor Issues Without Tests?

Dashboard indicators aren’t perfectly reliable for diagnosing resistor issues without tests. You should treat them as initial clues, not definitive proof. If you notice inconsistent vent temps, unusual blower speeds, or intermittent operation, consider tests for resistor value and airflow control. Be aware of resistor issue symptoms, such as persistent cold/hot bias and flickering gauges. Rely on precise measurements, not dashboard whimsy, and, if in doubt, test to confirm before replacing components.

How Often Should Blower Resistors Be Inspected for Early Signs?

You should inspect blower resistors every 6 to 12 months as part of routine maintenance. Check for signs of wear, unusual noises, heat discoloration, and airflow inconsistencies that hint at marginal blower lifespan. Establish a baseline, then monitor trends; if resistance values drift or airflow drops, schedule a more thorough test. Regular checks give you proactive control over performance, extending blower lifespan while maintaining system reliability and your freedom to troubleshoot confidently.

Can Other HVAC Components Mimic Resistor-Related Uneven Airflow?

Yes, several HVAC components can mimic resistor-related uneven airflow, affecting fan speed and airflow balance. You’ll see issues from duct leaks, faulty blend doors, or a failing blower motor, all altering static pressure and distribution. Impaired actuators or control modules may bias airflow to certain zones. Regular diagnostics guarantee balanced delivery; inspect for obstructions, test blower speed scaling, and verify temperature sensing aligns with vent outputs for consistent comfort.

Are Aftermarket Resistors More Prone to Uneven Performance Than OEM Parts?

Irony aside, yes—you’ll likely see aftermarket resistors more prone to uneven performance than OEMs. You’re choosing aftermarket quality, so resistor longevity tends to be shorter and variability greater, especially under load or heat cycling. If you push for freedom in specs, expect wider tolerances and quicker drift. You’ll want to verify compatibility, ratings, and thermal protection, because consistent airflow matters. In short: OEMs usually win for reliability; aftermarket may compromise longevity and steadiness.