How to Revive a Car After Long Storage With Minimal Rodent Damage While Parked

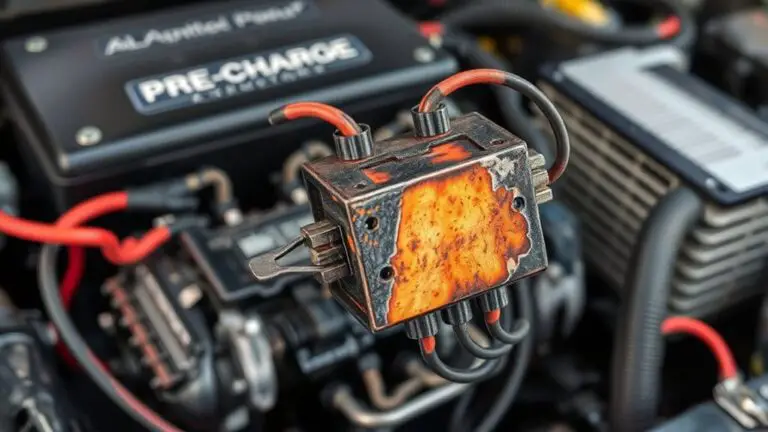

To revive a car after long storage with minimal rodent damage, start with a methodical exterior and interior inspection to identify bite marks, nests, leaks, and corrosion, then clear clutter and sanitize surfaces. Check the fuel system, lines, and tank for sediment or deterioration; replace filters and purge stale fuel. Inspect wiring for gnaw marks,…