How to Prepare Your Car and Tools Before Tackling Complex Electrical Gremlins

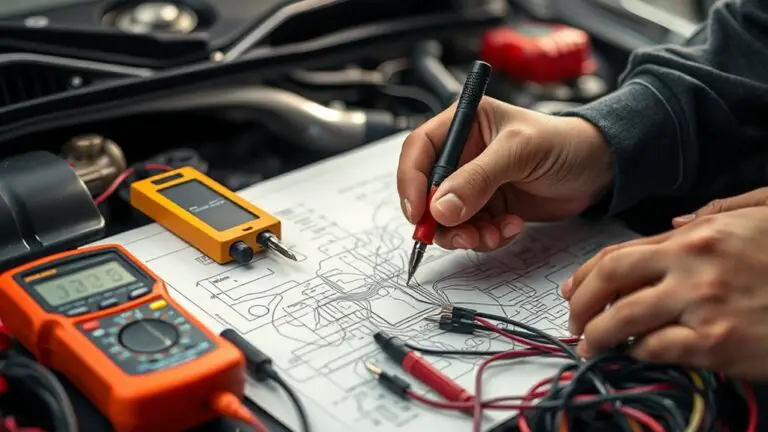

Before you tackle complex electrical gremlins, set a clear safety plan: park or neutral with the parking brake on, disconnect the battery, and wear gloves and eye protection. Organize a stable workspace with good lighting, labeled zones, and a tidy tool zone. Gather diagnostic gear, spare fuses, relays, and a portable power source. Define goals,…