Cost and Time Estimate to Fix AC Relay Failure

You’ll get a data-driven cost and timeline for diagnosing, replacing, and testing an AC relay fault. Expect a diagnostic check to identify coil burnout, contact wear, or arcing, followed by parts like coil or relay replacements and OEM components. Labor varies by unit and access, with total repairs typically staying within a narrow range, plus potential extra costs for wiring or delays. You’ll see a step-by-step schedule and risks, and more details soon.

Understanding AC Relay Failures

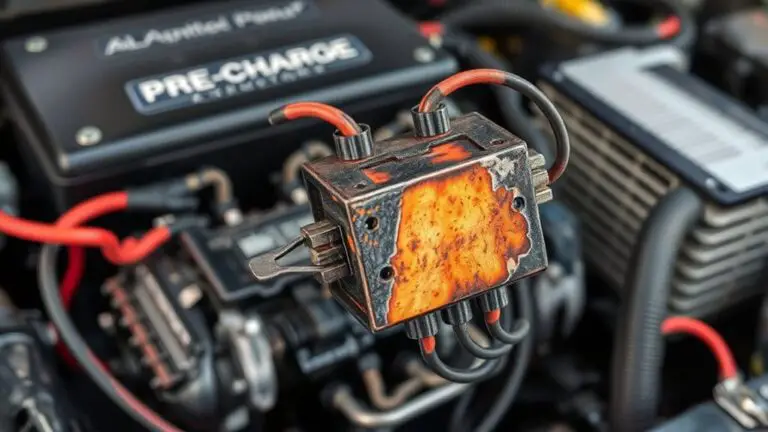

AC relays can fail in several ways, but most issues stem from coil burnout, contact sticking, or arcing at the contacts. In understanding AC relay failures, you focus on how the relay function governs circuit control and safety. Coil burnout reduces or eliminates actuation, making control unreliable and stressing the power path. Contact sticking traps the load in an undesired state, risking overheating and degraded performance. Arcing at the contacts degrades contact surfaces, increases resistance, and shortens life. To diagnose, you map symptoms to potential failure modes, then verify with measured coil resistance, contact continuity, and insulation integrity. Different relay types address distinct needs: electromechanical units offer clear actuation but wear; solid-state relays provide fast switching with no mechanical wear; and hybrids blend traits for specific duty cycles. Your assessment should articulate the expected failure mode relative to duty cycle, load, and environmental stress, guiding targeted maintenance and replacement decisions.

Signs Your Relay Needs Repair

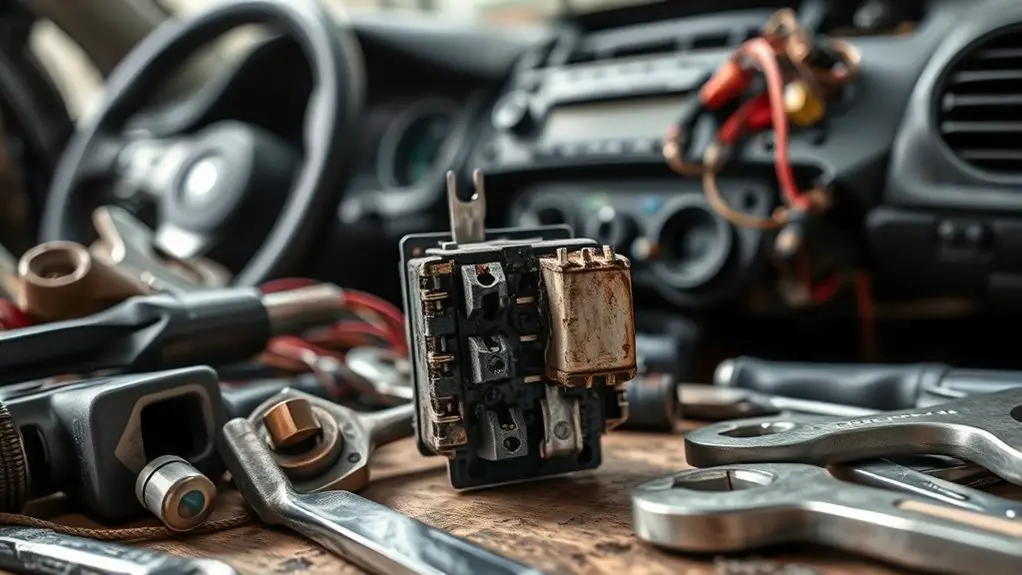

Common symptoms indicate when your relay needs repair, including intermittent or no cooling, clicking sounds, or excessive run times. Understanding the underlying causes—electrical wear, coil damage, or contact pitting—helps you anticipate failures before they escalate. Regular inspections should focus on these signals and align with planned maintenance to minimize downtime and cost.

Symptoms of Failure

There are several clear signs a faulty AC relay is affecting system performance. You’ll notice intermittent cooling, unexpected compressor cycling, or delayed restarting after a shutdown. Relay malfunction indicators include buzzing sounds, chattering, or a relay that sticks in the energized or de-energized state, leading to inconsistent voltage to the compressor. You might also observe voltage fluctuations at the control board or unusually high current draw during startup. Electrical connection issues can manifest as arcing or heat at relay terminals, shimmering contact surfaces, or burned smell near the relay pack. These symptoms point to degraded contact reliability or coil weakness, not external wiring alone. Isolate the relay for testing before blaming other components, and document observed patterns for accurate troubleshooting and service planning.

Common Causes

Worn contacts, coil or magnet degradation, and poor mounting are the primary signs your relay needs repair, often revealing why the system’s switching becomes unreliable.

- 1) Relay overheating signals internal resistance rise and contact wear, reducing actuation precision.

- 2) Electrical surges stress coils, accelerating insulation damage and chatter.

- 3) Mechanical looseness or vibration loosens terminals, causing intermittent openings/closings.

- 4) Contaminants or corrosion create arcing paths, increasing contact resistance and sticking behavior.

These root causes map to symptoms you’ll observe in operation: erratic cycling, delayed responses, or unexpected shutdowns. Addressing them early minimizes wear on drivers and loads. Maintain clean mounting, verify torque specs, and inspect for heat marks. If overheating or surge events recur, you likely need relay replacement or coil rewinding to restore reliable control.

When to Inspect

A good time to inspect is at the first sign of inconsistent switching: listen for chatter, note delayed actuation, or unexpected shutdowns, then verify if contact wear, coil degradation, or mounting looseness could be the cause. When you perform an inspection, focus on functional symptoms that indicate degradation rather than isolated faults. Signs include erratic switching, reluctance to energize, and premature relay chatter under steady load. Use a systematic approach: assess contact wear, coil resistance drift, and mounting integrity, and confirm wiring torque. Establish preventive maintenance triggers rather than relying on ambient age alone. Set an inspection frequency that aligns with load variability and duty cycle, documenting findings and corrective actions. Timely inspection supports reliable operation, safer startup, and a clearer cost/time estimate for fixes.

How Technicians Assess Cause and Scope

You’ll start by identifying the failure cause through targeted testing and symptom correlation. Then, you’ll assess scope by mapping affected components, electrical paths, and potential collateral damage. Finally, you’ll document constraints and uncertainties that influence the cost and time estimates for repair.

Diagnose Failure Cause

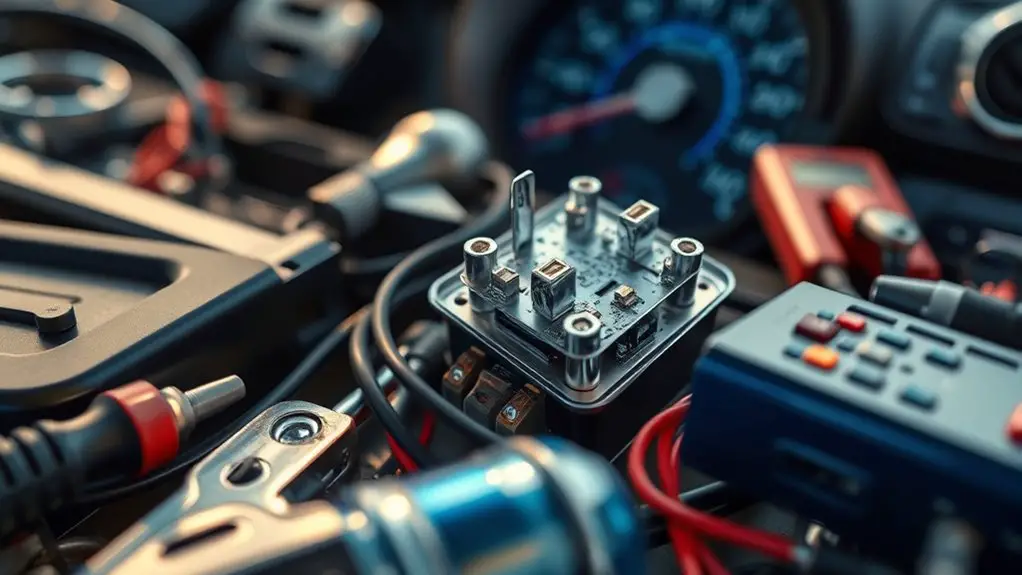

Diagnosing the failure cause starts with a structured, data-driven assessment: identify symptoms, confirm test results, and map them to likely fault modes.

- relay diagnostics: you compare observed behavior to expected electrical profiles, noting anomalies in switch timing and coil response.

- electrical testing: you perform controlled measurements (voltage, resistance, continuity) to validate or refute hypotheses.

- symptoms validation: you correlate on-site signs with laboratory findings to sharpen fault localization.

- fault mapping: you align test outcomes with probable causes, prioritizing root vs. symptomatic issues.

You document findings succinctly, then project impact on repair effort, downtime, and cost, keeping scope intact and decisions data-driven. You stay precise, avoiding irrelevant detail, and preserve a sense of controlled autonomy in your diagnostic flow.

Scope Assessment Factors

Scope assessment factors weigh what, how, and when to repair. You’ll map cause zones, evaluate symptoms, and quantify risk, guiding a precise scope evaluation. This step separates viable repair options from unnecessary work, ensuring you don’t overstep budget or downtime. You consider reliability, safety, and system interdependencies, then translate findings into actionable tasks and timelines. The focus is on evidence, not guesswork, so you compare component condition, fault latency, and accessibility. Your goal: clarity that informs cost and time estimates without ambiguity. Repair options are ranked by feasibility, impact, and return on investment, then documented for decision makers.

| Factor | Evidence Type | Decision Outcome |

|---|---|---|

| Condition | Diagnostics | Prioritized actions |

| Access | Cabinet/space | Scheduling considerations |

| Safety | Compliance | Abort or proceed |

| Priority | Impact | Budget alignment |

Typical Parts and Labor Costs

Typical parts and labor costs for an AC relay failure vary by unit and region, but you can expect a modest parts bill and a straightforward labor charge for a standard residential system. You’ll want clear visibility into pricing drivers and how they affect your total.

1) parts pricing: coil and relay replacements, compatible OEM parts, and occasional accessory fees.

2) labor rates: technician time, diagnostic checks, and safe disconnection and reconnection practices.

3) variation factors: HVAC brand, system age, and accessibility of the panel or compartment.

4) total outlook: most repairs stay within a narrow band when no additional components are involved.

Scheduling, Timelines, and Potential Delays

Scheduling, timelines, and potential delays hinge on availability of parts, crew capacity, and access to the unit. You’ll align repair windows with part delivery, technician routing, and permit constraints, so your project starts without surprises. Scheduling conflicts arise when multiple requests compete for the same technician or crane, impactingCrew-availability buffers and causing cascading shifts in project timelines. To manage this, lock in a realistic window that accounts for diagnostic time, ordering lead times, and on-site constraints like access permissions and electrical isolation requirements. Your timelines should include a contingency for shipping delays, weather interruptions, and concurrent service calls. Track progress against a written baseline, updating stakeholders as milestones shift. If early diagnostics indicate complex wiring or component replacement, expect extended durations and adjust resource loading accordingly. Communicate clearly about risk factors, required access, and acceptable downtime to preserve clarity and minimize disruption to occupants or operations. Maintain flexibility while preserving commitment to the scheduled delivery of service.

Tips to Maximize Value and Prevent Recurrence

Maximizing value and preventing recurrence start with clear, data-driven fixes and a focus on durable outcomes. You’ll protect investment by targeting root causes, validating with measurements, and planning for reliability. Emphasize preventive maintenance to extend life, reduce downtime, and shave energy costs.

Maximize value with data-driven fixes, durable outcomes, and preventive maintenance to extend life and cut downtime.

1) Schedule regular diagnostics and component testing to catch wear before failure, documenting results for traceability.

2) Implement energy-efficient operating practices, calibrating controls for ideal compressor and relay duty while minimizing surges.

3) Use durable parts and proper torque/connection procedures to prevent micro-arcing and loose contacts that trigger repeats.

4) Establish a maintenance calendar with triggers for inspection, cleaning, and coil resistance checks, tying actions to performance metrics and budget.

Frequently Asked Questions

Do Warranties Cover AC Relay Replacements for Cooling Systems?

Yes, warranties can cover AC relay replacements, but it depends on your policy’s warranty terms and coverage limits. You’ll want to verify if the relay failure is classified as a covered component and whether misuse or preexisting conditions voids the claim. Review your warranty terms for exclusions, required service dates, and any deductible. If you qualify, you’ll typically pay only the diagnostic fee, with the rest covered up to the coverage limits.

How Is Labor Cost Determined for Complex Relay Failures?

The labor cost for complex relay failures depends on labor rate factors and technician expertise. You’ll see higher rates if the issue requires advanced diagnostics, board work, or multiple systems. Your total reflects time spent, travel, and any required testing. You’re paying for specialized skills, iterations, and efficiency. Make sure the quote itemizes labor hours by task, plus any overtime or permit fees. You’ll gain clarity when the technician explains how expertise drives accuracy and reduces repeat visits.

Are There Hidden Fees Beyond Parts and Labor?

Yes, there can be hidden costs beyond parts and labor. You’ll want to scrutinize repair estimates for additional fees like diagnostic charges, trip or after-hours rates, disposal, or refrigerant handling. Review every line item, confirm scope, and ask for a written breakdown. If you see vague “miscellaneous” charges, request specifics. Transparent repair estimates help you compare options and avoid surprise hidden costs while preserving your freedom to choose.

Can I DIY a Relay Repair Without Voiding Warranties?

You can’t safely DIY a relay repair without risking warranty implications. Satirical as it sounds, you’ll expose yourself to relay repair risks like improper insulation, overheating, and fire hazards. If your unit is under warranty, do-it-yourself work voids coverage and shifts liability to you. Stick to manufacturer guidelines or certified service to preserve protections; your freedom to tinker ends where warranties or safety concerns begin.

How Soon Can Urgent Repairs Be Scheduled?

You can schedule urgent repairs as soon as today, depending on your location and availability. An emergency service can typically arrive within a few hours and begin diagnostics immediately. The repair timeline varies with parts and access, but you’ll usually have a clear ETA after triage. You’ll want proactive coordination, concise updates, and transparent costs to preserve your freedom while you regain reliable cooling.