Diagnosing Loud Exhaust Noise: What the Catalytic Converter Symptoms Mean

A noisy exhaust often marks changes in backpressure and flow, so start by listening for where the sound comes from and whether it changes with RPM. A deteriorated or blocked catalytic converter can shift tone toward harsh, loud notes or hiss, and may trigger a power drop or check engine light. Rattles point to loose components, while popping can signal leaks or rich fuel. If symptoms persist, you’ll uncover more precise diagnostic steps as you continue.

Understanding Catalytic Converters and Why They Affect Noise

Catalytic converters, essential for reducing harmful emissions, also influence exhaust tone and volume through their internal honeycomb catalyst matrix and the overall exhaust flow path. You’ll notice that the converter’s function hinges on guiding exhaust through coated substrates, promoting chemical reactions that reduce pollutants without obstructing flow excessively. When flow remains smooth and evenly filtered, exhaust noise stays within predictable bounds. Conversely, a degraded or damaged matrix can alter backpressure, subtly shifting tone and perceived volume. The catalytic converter function intersects with exhaust emission reduction in a way that preserves engine efficiency while limiting hydrocarbons, carbon monoxide, and nitrogen oxides. Materials choice and substrate geometry determine how heat is managed and how quickly reactions occur, influencing subtle timing and resonance within the exhaust system. In practical terms, you’re balancing effective emission control with maintaining a controlled acoustic profile, ensuring regulatory compliance without sacrificing performance or responsiveness.

Common Loud Exhaust Symptoms to Recognize

You may notice a sudden exhaust noise that starts without warning, signaling a possible leak or component failure. Rattling or popping sounds can indicate loose heat shields, broken manifolds, or damaged exhaust piping. Increased engine strain often accompanies these symptoms, suggesting restricted flow or misalignment that warrants prompt inspection.

Sudden Exhaust Noise

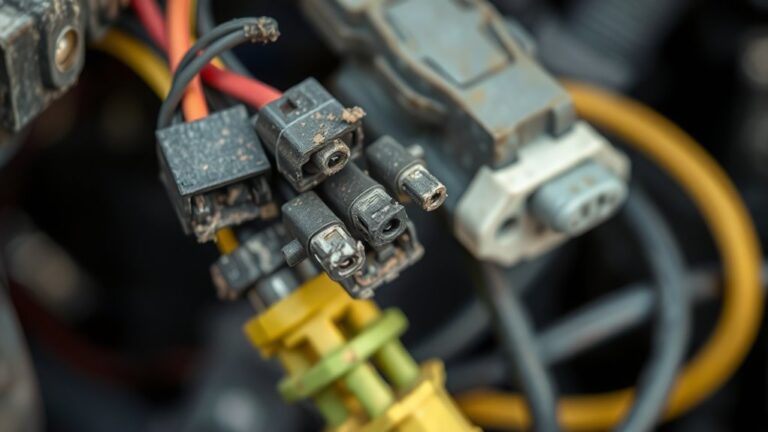

Sudden exhaust noise is typically a rapid, unexpected increase in sound level, indicating a leak or obstruction in the exhaust path or a failure in the muffler, catalytic converter, or manifold. You’ll want to pinpoint whether the surge originates upstream or downstream of the sensor, as this informs diagnosis and repair strategy. The causes of noise often involve structural damage, loose hangers, or worn gaskets, all of which can elevate sound without immediate power loss. You may notice a minor torque change or delayed response, signaling an impact on performance. Quick assessment prevents further damage and guarantees emissions integrity.

- Structural damage and leaks

- Loose hangers or clamps

- Worn gaskets or seals

- Downstream component obstruction

Rattling or Popping

Rattling or popping noises often indicate a loose or damaged component in the exhaust path, such as a broken heat shield, loose hangers, or a fractured pipe, which allow metal to vibrate at engine RPM or exhaust flow changes. When you hear rattling sounds, inspect mounting points and shields for looseness and obvious cracks. Popping noises typically arise from backfire or unsteady flow, signaling leaks or improper resonance within the exhaust manifold or catalytic system. You should confirm that clamps and gaskets seal properly and that flexible sections aren’t collapsing under load. Note the location and timing of the sounds relative to RPM and gear, as these details narrow the fault to a specific segment. If symptoms persist, proceed with noninvasive pressure checks to avoid further damage.

Increased Engine Strain

Increased engine strain manifests as louder exhaust under load and at higher RPM, signaling restricted flow or a misfiring condition that forces the engine to work harder.

- You may notice reduced acceleration response and a need to downshift to maintain speed

- Engine feels surging or stuttering under load, indicating inconsistent combustion

- Exhaust sounds louder or more metallic during acceleration

- Hot under-hood components and higher operating temperatures point to decreased exhaust efficiency

This symptom highlights compromised engine performance and exhaust efficiency. Diagnose by checking for intake leaks, faulty spark, or clogged catalytic converter. Monitor fuel trim and misfire codes, and verify oxy sensor readings. Address root causes promptly to restore power, improve throttle response, and maintain efficiency. Continuous strain risks component damage and degraded overall performance.

Rumbling Engine Noise: What It Signals About the Converter

A rumbling engine noise can indicate issues with the exhaust converter, guiding you to inspect its condition and function. You’ll notice a low-frequency roar that changes with RPM, suggesting abnormal flow or substrate restriction. In catalytic converter performance terms, the catalyst may be overheating, aging, or clogged, reducing conversion efficiency and raising backpressure. This manifests as sustained exhaust resonance rather than intermittent ticking or popping. Conduct exhaust noise analysis by correlating sound characteristics with engine load, speed, and temperature; a steady rumble at light throttle points to converter-related restriction, while a louder, broader rumble at high RPM implicates thermal or substrate damage. Check for external leaks that amplify sound, but distinguish them from internal flow faults. Monitor fuel trim stability and oxygen sensor signals; persistent lean or rich conditions can aggravate catalyst stress. If the rumble persists after addressing leaks and engine health, schedule a diagnostic with proper backpressure testing to verify substrate integrity and convert efficiency.

Rattling and Loose Components: Diagnostic Clues to Check

Rattling and loose components can produce distinct, metallic exhaust noises that vary with engine RPM. Start by checking for loose heat shields, clamps, hangers, bolts, and exhaust system joints, noting any movement or contact with nearby parts. This overview covers common rattling causes and a focused loose-parts checklist to guide inspection.

Rattling Causes Overview

Rattling noises in an exhaust system typically point to loose or damaged parts that resonate at operating speeds. In this overview, you’ll identify common sources that generate rattles without delving into loose parts checks. Focus on how rattling noises align with exhaust flow and mounting integrity, and how converter vibrations can amplify symptoms. Your aim is to distinguish between transient thermal expansion sounds and persistent metal-on-metal contact, guiding diagnostic decisions with measured observations.

- Loose heat shields and hanger straps that flutter at higher rpm

- Debris or broken baffles within the muffler contributing to resonance

- Converter vibrations transferring into the exhaust piping

- Damaged or shifted mounting studs causing asymmetric vibration paths

Loose Parts Check

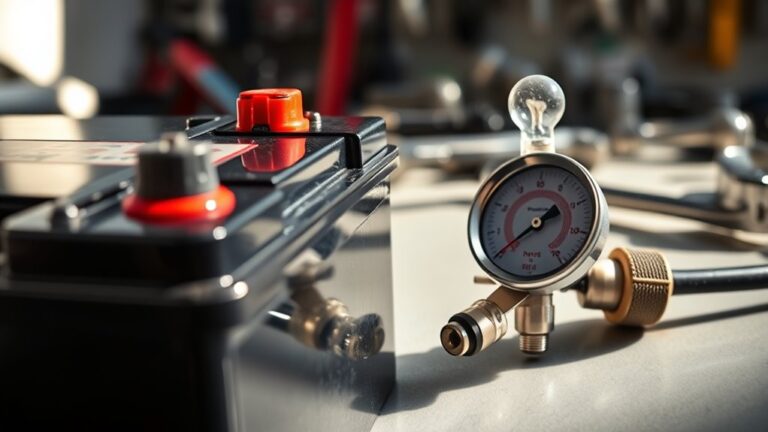

Loose parts can produce distinctive rattles when the exhaust system is under load, so you should listen for timing with RPM and note whether sounds change with engine deceleration or throttle position. You’ll verify suspected loose components by careful palpation and vibration checks, then confirm with diagnostic tools. Inspect hangers, heat shields, clamps, and reducers for looseness or missing fasteners; movement indicates a culprit. Distinguish between exhaust leaks and loose parts by locating exact noise sources and comparing to engine RPM. Use a bore scope or stethoscope to isolate rattles, and test-fit suspect parts off the system when safe. Gather data with exhaust system pressure tests to corroborate findings.

| Component | Symptoms/Checks |

|---|---|

| Hangers | Visual plus light movement under load |

| Shields | Rattle during deceleration |

| Clamps | Loose or missing fasteners |

| Mating joints | Audible movement, verify seating |

Roaring or Popping: Exhaust System Failures You Might Be Hearing

A roaring or popping exhaust is often a sign of a leak or restriction in the exhaust path, which can alter backpressure and create abnormal sound characteristics.

- You may hear sharp pops when the engine decelerates, stemming from unburned fuel igniting in the exhaust stream, altering sound frequency and tone.

- A consistent roar often signals a hole or failed joint, allowing exhaust gas to escape before reaching the muffler, increasing overall noise output.

- A rasp or metallic clatter can indicate loose or damaged hangers, brackets, or heat shields that change resonance without changing engine timing.

- Popping under acceleration can reflect a rich fuel condition or intake/exhaust coupling issue, producing higher-pitched sound elements at specific RPM ranges.

These clues emphasize exhaust leaks, backpressure changes, and the importance of inspecting for leaks at joints, gaskets, and the piping path to prevent further system damage.

Distinguishing Converter Issues From Other Exhaust Problems

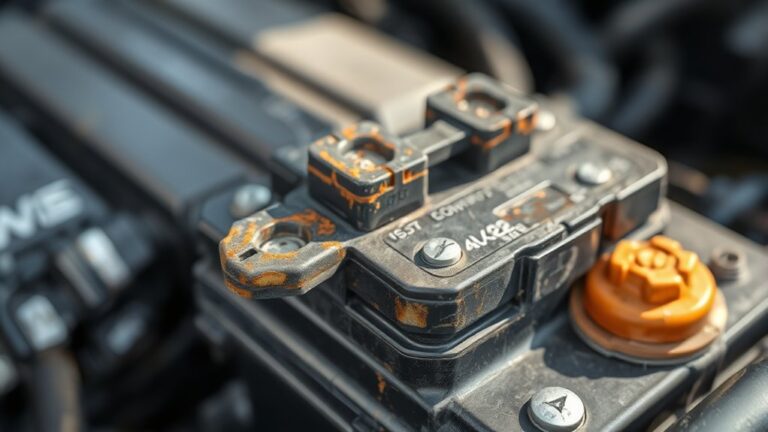

Distinguishing converter issues from other exhaust problems requires isolating symptoms tied specifically to the catalytic converter, rather than to leaks, rattles, or muffler wear. You’ll look for behavior tied to backpressure, catalyst temperature, and downstream exhaust flow, not generic noise or loose components. Key signals include sudden loss of power with a forced, engine-management light, and unusually high backpressure readings suggesting converter blockage, or a harsh, metallic exhaust note that doesn’t change with rpm. Exhaust leaks often produce hissing or odor at joints, while rattles point to hardware rather than catalytic function. Use diagnostic codes and a pressure test to separate converter problems from leaks or muffler wear. If a blockage exists, the upstream side will heat rapidly while the downstream side remains cooler. Table illustrates relationships and action steps.

| Symptom | Likely cause | Recommended check |

|---|---|---|

| Power loss | Converter restriction | Measure backpressure |

| Audible change | Leaks | Inspect joints |

| Temperature anomaly | Blockage vs. failure | Compare upstream/downstream temps |

Safe, Step-by-Step DIY Diagnosis Techniques

Safe, step-by-step DIY diagnosis involves a structured approach that prioritizes accuracy and personal safety. You’ll perform a controlled assessment of the exhaust system, focusing on consistent methods and measurable cues. Approach each check methodically to isolate abnormal sounds, leaks, or heat signatures without guesswork. You’ll document observations, compare against baseline conditions, and use standard diagnostic parameters to avoid misinterpretation.

Safe, step-by-step DIY diagnosis prioritizes accuracy and safety while methodically assessing the exhaust system and documenting measurable observations.

- DIY diagnostics: establish a repeatable procedure, log each finding, and verify by cross-checking symptoms with multiple tests

- Exhaust inspection: inspect joints, clamps, hangers, and the catalytic converter housing for signs of leakage, corrosion, or damage

- Sound profiling: record vibration frequencies, changes in tone, and decibel levels to differentiate rattles, hisses, and drone

- Safety controls: disconnect power, wear eye protection, and secure the vehicle on level ground with wheels chocked

Follow these steps to build a trustworthy symptom map, then determine if further evaluation is needed.

When to See a Professional for Exhaust and Converter Repair

When should you call a pro for exhaust and converter repairs? Mechanical issues can escalate quickly, so you should seek a professional assessment when symptoms persist or worsen after initial checks. If you notice persistent loud exhaust, rattling, or hissing under acceleration, schedule an exhaust evaluation to identify leaks, broken hangers, or damaged components. Pay attention to decreased fuel efficiency, unusual smells, or dashboard codes related to emissions, as these signals often indicate catalytic converter or O2 sensor problems. If you hear exhaust popping, experience heavy smoke, or the engine misfires, don’t delay—delays can damage the catalytic converter and downstream systems. For safety and compliance, have any suspected exhaust leaks inspected promptly to prevent harmful emissions or fire risks. A professional assessment should include a visual inspection, pressure testing, and, when needed, a diagnostic scan to confirm converter health and screen for upstream or downstream faults. Trust the data from an exhaust evaluation to guide necessary repairs or replacements.

Frequently Asked Questions

Can a Clogged Catalytic Converter Cause Fuel Economy Drop?

Yes, a clogged catalytic converter can reduce fuel economy. When exhaust flow is restricted, your engine works harder, lowering fuel efficiency and increasing backpressure. This exhaust blockage disrupts ideal air-fuel mixing and exhaust scavenging, causing misfires, reduced power, and higher throttle input. You may notice slower acceleration and more frequent fuel consumption. If you suspect a blockage, inspect for heat, smell, or rattling, and consult a technician to prevent downstream damage and restore efficiency.

Do Exhaust Leaks Trigger Check Engine Light Immediately?

Yes, an exhaust leak can trigger a check engine light, but not always immediately. When your exhaust system has a leak, you may introduce unmetered air or abnormal backpressure that the engine control unit detects as a fault. If the leak is severe or affects O2 sensor readings, the check engine illumination often follows promptly. However, minor leaks might take longer to register. Inspect the exhaust leak areas and monitor for codes.

How Long Do Converters Typically Last Under Heavy Use?

A catalytic converter typically lasts about 70,000 to 100,000 miles under normal conditions, but heavy usage can shorten that lifespan. When you push the engine hard, heat cycles and unburned fuel increase, accelerating converter aging. If you regularly tow, drive uphill, or hot-start frequently, expect converter lifespan to decline, possibly under 50,000 miles. Monitor for reduced performance, odor, or codes, and plan inspections accordingly to preserve efficiency during heavy usage.

Can Aftermarket Parts Invalidate Converter Warranties?

Yes, aftermarket parts can invalidate converter warranties. About 40% of manufacturers void coverage when non-OEM parts affect emissions systems, so you’d risk losing warranty protection if a trip-detecting failure occurs. You should assess converter performance with OEM-compliant replacements first. If you opt for aftermarket, document part numbers and installation details, and weigh the potential warranty impact against cost savings. Know that some warranties remain intact under specific criteria and approved parts.

Are Catalytic Converter Diagnostics Safe for DIY Beginners?

Yes, catalytic converter diagnostics can be safe for DIY beginners if you proceed carefully with proper knowledge and precautions. You’ll learn catalytic converter basics and use diagnostic tools to interpret readings without tampering with the system. Stay within manufacturer guidelines, avoid hot exhaust components, and disconnect power when needed. Approach methodically, document results, and don’t force components. If unsure, consult a pro.