How Load and Towing Lead to Bouncy Ride and How to Fix Them

When you tow or carry a heavy load, weight shifts and suspension loading cause bounce, dive, and sway, dulling steering and raising tire wear. You fix it by balancing tongue weight, keeping front axle loaded appropriately, and using proper hitch height and ball size. Check tire pressures cold, match them to load, and upgrade suspension components if needed. Verify dampers and springs suit the load, and consider sway control or load-leveling gear. More specifics ahead.

Understanding Why Load and Towing Cause a Bouncy Ride

When you tow or load a vehicle, the combination’s dynamic behavior changes because weight distribution and moment effects alter suspension action and tire contact with the road. You’ll notice a bouncy ride when the load shifts or the tongue weight isn’t balanced, because springs and dampers must absorb more vertical and yaw forces than designed. This isn’t mystery physics; it’s practical load management. Too much rear weight lightens the front axle, reducing steering feel, while excessive front load can compress the wrong springs, increasing squat and rebound. On long pulls, suspension fatigue can amplify oscillations, so you feel every rut and ripple rather than steady stability. Ascertain hitch alignment, distribute weight evenly, and verify axle load ratings. Set up correct dampening by matching tire pressures to payload and using appropriate stabilizers if needed. In short, control weight placement, maintain suspension limits, and monitor how normal road irregularities become a persistent, controllable vibration.

How Weight Distribution Affects Suspension Performance

Weight distribution directly governs how suspension components share loads and respond to road inputs. When weight shifts during acceleration, braking, and cornering, you feel how the springs, dampers, and anti-sway systems react. Proper balance minimizes squat, dive, and body roll, improving grip and control. You’ll notice that weight transfer affects how effectively suspension tuning achieves consistent tire contact patches and predictable handling. Misbalanced loads raise peak forces on one axle, increasing wear and compromising ride quality. Tuning focuses on aligning spring rates, damping coefficients, and anti-roll behavior with typical load scenarios, so you maintain desired ride height and control authority.

- Monitor load paths and adjust spring/damper settings to counteract weight transfer during dynamic maneuvers.

- Fine-tune suspension geometry and anti-roll stiffness to preserve tire contact and minimize pitch and roll, especially under towing loads.

- Validate through controlled testing to verify consistent feel, traction, and ride stability across road conditions.

The Role of Trailer Hitch Setup and Towing Dynamics

Trailer hitch setup and towing dynamics directly influence load transfer, stability, and control during movement. You’ll discover how hitch height, ball size, and weight distribution affect trailer sway and braking feel, and why precise trailer hitch adjustment matters for safe, predictable performance. Proper coupling minimizes hitch load oscillation, improves tire loading, and preserves steering response under varying speeds and road conditions. Towing capacity isn’t just a number—it’s the ceiling for safe acceleration, braking, and maneuvering with a given trailer. Use ballast, spring bars, or sway control as needed, but confirm compatibility with your vehicle’s rated capacity and hitch class. Fine-tuning at the drawbar and ensuring correct pin and clip installation reduces bounce and enhances control.

| Benefit | Quick Action |

|---|---|

| Stability | Check hitch height and ball fit |

| Load transfer | Balance tongue weight within specs |

| Control | Verify wiring and sway control |

| Safety margin | Respect towing capacity |

| Responsiveness | Test light-to-mreaverse handling |

Note: Adjustments should stay within manufacturer specs.

Signs Your Vehicle Is Being Overwhelmed by Load

You’ll notice signs that your vehicle is carrying too much load, including excessive load symptoms that alter braking response and acceleration. Deteriorated handling cues—like sluggish steering and increased body roll—signal your suspension and chassis are under strain. Suspected suspension strain signs, such as uneven tire wear or bottoming out over bumps, warrant immediate load reassessment and safe driving adjustments.

Excessive Load Symptoms

Excessive load can push your vehicle beyond its practical limits, making handling and braking feel sluggish and unpredictable. When you’re overloaded, you’ll notice reduced steering response, longer stopping distances, and a feel of float or bounce over uneven pavement. You may also hear unusual tire, chassis, or suspension noises as components strain to cope with the extra mass. These signs point to excessive load and potential handling issues that demand action before a loss of control.

- Reduced steering precision and delayed input response

- Longer stopping distances and grabby or sinking brakes

- Unusual vehicle pitch, tire wear patterns, or suspension bottoming

Address the load, verify ballast, and restore balanced weight distribution to reclaim stable handling.

Deteriorated Handling Cues

When load is out of balance or excessive, handling cues become noticeably harsher and less predictable. You’ll notice steadiness fading: steering feels heavier, input lag grows, and midcorner corrections require more effort. Deteriorated handling shows up as micro-instabilities—front end push, rear squat, or nose-diving under braking—signaling the vehicle is overwhelmed. You may sense uneven braking pull or wandering lane position during gusts or lane shifts. These symptoms aren’t random; they reflect improper load distribution and degraded load management. To regain control, verify weight distribution, secure perimeters, and guarantee ballast is within manufacturer recommendations. Regularly check tire contact and inflation, as mismatch compounds handling loss. Addressing deteriorated handling promptly preserves safety margins and improves ride quality, aligning performance with freedom to drive confidently.

Suspension Strain Signs

Suspension strain shows up as the system struggles to absorb load via its springs, dampers, and mounts. When you’re carrying or towing heavier than designed, you’ll notice warning cues in ride quality and handling that point to limited component performance. This isn’t just bounciness—it’s a sign of suspension wear and imbalanced load distribution stressing the chassis. You want to preserve steering feel, tire contact, and overall safety, so watch for early strains rather than late failures. Addressing load balance at the source reduces long-term wear and keeps the system resilient.

- Uneven sag or nose-dive when braking, indicating poor load distribution.

- Excess body roll, creaks, or mounting shifts that signal mounting wear and mounting point stress.

- Persistent roughness or bouncing after minor road impacts, reflecting dampers overworked.

How Tire Pressure Relates to Stability Under Load

Correct tire pressure directly influences load stability, as under- or over-inflation changes contact patch shape and handling feel. You’ll see the load stability link through consistent inflation and adherence to the vehicle’s proper inflation guidelines. Start with the manufacturer’s specs, then verify tire pressure under load to maintain predictable performance.

Tire Pressure Effects

Tire pressure directly affects stability under load: underinflation causes the tire to deform more at the contact patch, increasing sidewall flex and heat buildup, while overinflation reduces the footprint and can worsen handling and ride harshness. You’ll notice how pressure choices influence tire wear and load balance over long pulls and rough roads.

- Maintain recommended PSI to preserve even tire wear and predictable load balance across axles.

- Monitor seasonal changes; temperature shifts alter effective pressure and ride stiffness.

- Check pressure when tires are cold and before towing; small changes impact stability, steering feel, and control.

In practice, precise pressure supports predictable handling, reduces pull, and keeps tires from developing hot spots under load.

Load Stability Link

Under load, tire pressure directly shapes contact patch behavior and, consequently, stability: when pressure is too low, the tire deforms more, increasing slip potential and sidewall flex; when too high, the footprint narrows, reducing grip and making steering less predictable. The link between load and stability hinges on maintaining a consistent footprint that matches load expectations. Proper pressure keeps tread contact uniform across the tire’s width, improving traction and steering feel when towing. In practice, you’ll fine‑tune load management by accounting for cargo weight, distribution, and hitch dynamics, then adjust tire pressures accordingly. For towing techniques, verify pressures before departure and during long runs; small tweaks at each stop help sustain stability, reduce sway, and preserve control without sacrificing efficiency.

Proper Inflation Guidelines

To keep stability under load, you must match tire pressures to both cargo weight and trailering demands. Proper inflation guidelines balance grip, heat, and wear, reducing bounce and unpredictable handling. You’ll rely on accurate tire pressure, not casual guesses, and adjust with load changes, speed, and trailer setup in mind. Stay within manufacturer charts, verify cold readings, and recalibrate after loading or detaching. Inflation tips that save you effort include checking tires when cold, using a reliable gauge, and accounting for seasonal variations. Consistency matters: keep all tires within the recommended range, including spares.

- Check cold tire pressure before a trip and after loading.

- Use a quality gauge and verify readings with multi-point checks.

- Reassess pressure after long climbs, hot days, or changing cargo.

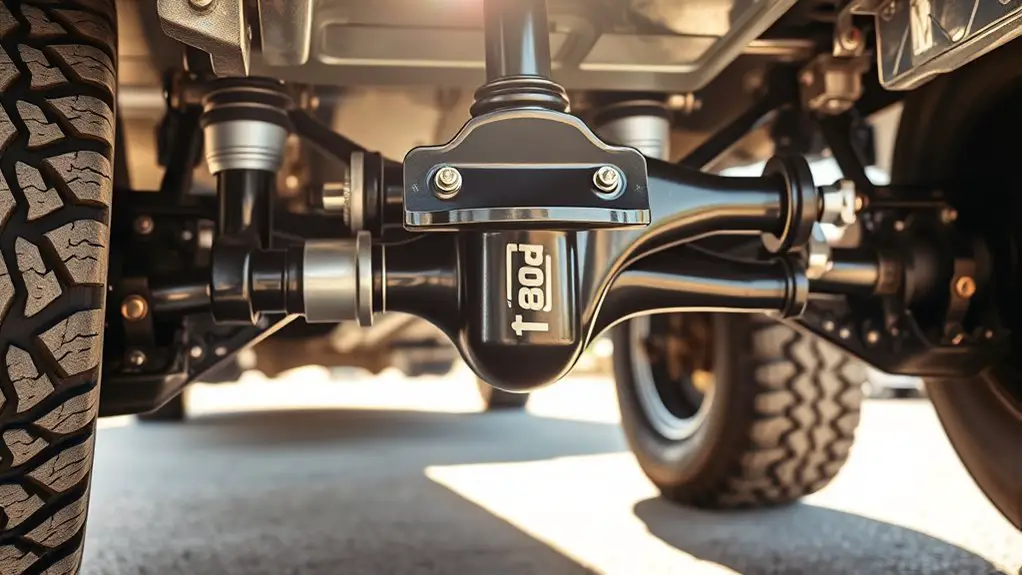

Suspension Components That Take the Brunt of Extra Weight

Suspension components bear the brunt when you tow or load heavily, so you’ll want to understand which parts endure the most stress and how they behave under extra weight. Your primary load-bearing areas are shocks, springs, and mounting hardware. Shock absorbers control dynamic motion, dampen oscillations, and prevent tire hop; under heavy load, they work harder and can overheat or lose rebound control. Coil springs support axle weight, keep ride height consistent, and absorb vertical energy; overloaded springs squat, worsen pitch, and can cause tire rubbing. Leaf springs, control arms, and bushings also take strain, affecting alignment and steering feel. Regular shock absorbers maintenance helps spot leaks, worn bushings, and reduced damping early. If you’re exploring performance tweaks, coil spring upgrades can restore proper ride height and stiffness without compromising safety. Stay mindful of alignment and tire compatibility, and balance load with appropriate spring and damper choices for predictable handling.

Techniques for Achieving Proper Weight Distribution

Achieving proper weight distribution starts with a measured balance of axle loads and hitch/tow vehicle mass. You’ll pursue even load sharing across axles and a stable hitch, then adjust dynamically as you load or unload. Use precise measurements, then implement proven weight balancing techniques to reduce sway and bounce. Consider how your setup handles tongue weight, rear axle load, and front-end lift, and pick options that maintain control at highway speeds. Weight distribution isn’t static; choose adaptable tools that suit timber, cargo, or watercraft without compromising overall balance. When selecting load leveling options, prioritize predictable response, ease of use, and compatibility with your vehicle and trailer geometry.

- 1) Weight balancing techniques: measure, compare, and rebalance to keep axle loads within spec.

- 2) Load leveling options: choose adjustable or automatic solutions that respond to road conditions and payload shifts.

- 3) Tongue and hitch setup: verify tongue weight, hitch height, and clearances for consistent performance.

Practical Adjustments to Improve Ride Quality

Practical adjustments to improve ride quality build on solid weight distribution and adaptive load handling by fine-tuning how the setup responds to road conditions. You’ll focus on predictable behavior, not magic. Suspension tuning is your primary tool: dial spring rates, damping, and anti-squat to match your vehicle’s handling envelope with towing or cargo. Use progressive springs where possible to soften lows and stiffen under higher loads, reducing pitch and bounce without harsh impacts. Load leveling helps maintain a constant ride height, preserving tire contact and steering feel as weight shifts. Fine-tune the hitch position and ballast to keep the center of gravity low and centered, minimizing squat and dive. Verify alignment and tire pressures for the loaded state, then validate comfort at highway speeds and on rough surfaces. Document changes, recheck stability under braking, and avoid overcorrection that creates new wandering or tramlining.

When to Consider Upgrades for Enhanced Stability

Upgrading for stability makes sense when your current setup no longer keeps pace with payload changes, road conditions, or handling targets. You’ll assess whether your tow vehicle and trailer combination can consistently maintain control, steering feel, and consistent tire contact under load. If instability, excessive sway, or abrupt pitch persist after tuning, consider targeted upgrades that preserve ride comfort while boosting predictability.

Upgrading for stability suits evolving payloads, road conditions, and handling targets for safer, more predictable towing.

1) upgraded shocks and weight distribution: optimize damping and load balance to reduce squat, dive, and trailer sway, improving overall stability and ride feel.

2) suspension kits and towing equipment: align axle geometry, springs, and hitch components to support heavier loads without compromising handling.

3) weight distribution and stability enhancements: install properly matched components to maintain tire load, reduce hitch-induced destabilization, and enhance steering response.

Choose a focused package that preserves ride quality while delivering predictable handling and safer towing performance.

Frequently Asked Questions

How Does Tongue Weight Affect Ride Stability?

Tongue weight is essential: too little or too much disrupts ride stability. About 10–15% of trailer weight is ideal for most setups, improving tracking and reducing sway. You’ll want balanced load distribution to keep the trailer tugging evenly behind you. With proper tongue weight, ride stability improves, dampening bounce and curbing excess rider fatigue. Check hitch load with a scale, adjust ballast, and test tow response to maintain consistent stability on curves and hills.

Can Factory Shocks Handle Towing Weight Safely?

Factory shock performance: generally not advisable to rely on stock shocks for towing near or beyond capacity. If you’re near towing capacity limits, factory shocks may fade, ride become unstable, and control suffer. For safer handling, upgrade to higher-rated shocks or a proper suspension upgrade designed for towing. Check your vehicle’s towing limits, ballast distribution, and sway control. You deserve a calmer, more controlled ride with components rated for the load you’re pulling.

Do Sway Bars Improve Ride With Heavy Loads?

Yes, sway bars can improve ride with a heavy load. They increase roll control, boosting heavy load stability and reducing bounce during cornering and braking. Sway bar effectiveness depends on bar stiffness, mounting points, and proper end-link alignment. For best results, choose bars designed for your vehicle’s suspension and guarantee correct torque and clearance. If you tow often, verify compatibility with your hitch setup and consider proportional damping in shocks for balanced, confident handling.

Does Vehicle Aerodynamics Influence Bouncing With a Trailer?

Yes, vehicle aerodynamics influence bouncing with a trailer. You’ll reduce it by minimizing aerodynamic drag and optimizing trailer design. Focus on smooth underbody airflow, proper hitch height, and stabilizing spoilers or fairings where appropriate. Keep drag down to lessen crosswind effects and pitch oscillations. In practice, align trailer design with your tow vehicle, balance loads for stable rebound, and test adjustments at speed to find the sweet spot that preserves ride quality.

How Quickly Do Shocks Wear With Constant Towing Use?

Shocks wear gradually, not instantly, and constant towing accelerates that process. Expect shock absorber lifespan to shorten with higher towing frequency impact, especially under heavy loads or rough roads. If you tow regularly, anticipate quicker damping decline and plan inspections every 6,000–10,000 miles. You’ll notice reduced control and more bounce as seals age. Regularly check for leaks, performance loss, and rebound behavior to keep your rig feeling capable and within safe, practical limits.