How Temperature Affects Battery Fuse and Causes Poor Cranking in Cold Weather

Cold temperatures raise internal resistance and slow ion transport, so your battery delivers less current while fuses respond more sluggishly. You’ll see higher starter draw, slower voltage recovery, and potential voltage sag under load, all contributing to hard starts. In cold, electrolyte viscosity increases and diffusion drops, while impedance grows at low frequency, limiting cranking power. Check battery voltage, clean connections, and inspect fuses for resistance changes. If problems persist, you’ll uncover deeper causes as you explore further.

The Science Behind Cold Battery Chemistry

Cold temperatures slow battery reactions by increasing internal resistance and reducing ion mobility, which lowers available capacity and peak power. In this section, you’ll examine the core mechanisms shaping cold battery chemistry. You measure how electrolyte viscosity rises with tripled solvent stiffness, hindering ion transport and elevating activation energy for charge transfer. You quantify diffusion coefficients dropping by orders of magnitude, and you map how electrode kinetics shift from fast pseudocapacitance to diffusion-limited behavior as temperatures fall. You assess how grain boundaries and solid electrolyte interphase stability influence reaction pathways under cold reactions, noting that impedance grows where lithium intercalation faces sluggish kinetics. You track temperature-dependent entropy changes that alter reaction free energy, and you correlate these with measurable voltage depression and capacity loss. You emphasize reproducible methods, instrumentation calibration, and control of moisture and parasitic reactions to isolate intrinsic battery chemistry effects, delivering a concise, empirical understanding suitable for freedom-oriented engineering.

How Temperature Influences Battery Voltage and Capacity

Temperature affects both the voltage you observe and the usable capacity of a battery, primarily by altering reaction kinetics, internal resistance, and ion transport as temperature shifts. You’ll notice a higher voltage at elevated temperatures, but capacity gains from chemistry aren’t limitless; self-discharge and loss pathways still grow with time. As temperature falls, reaction rates slow, reducing electron transfer efficiency and manifesting as a voltage drop under load. This drop lowers apparent battery performance even before chemical limits bite. Narrow operating margins mean usable capacity contracts because chemical species mobilities decline and diffusion becomes rate-limiting, so you reach cutoffs sooner in cold conditions. The net effect is a steeper voltage sag during discharge, followed by quicker depth-of-discharge exposure. For accurate assessments, you should normalize measurements to a standard temperature or report temperature-compensated data. Understanding this relationship helps you anticipate performance losses and select appropriate charging strategies for varying ambient conditions.

Internal Resistance and Its Role in Cold Starts

Internal resistance dominates cold-start performance because ion transport and interfacial kinetics become rate-limiting as temperature falls. You observe higher voltage drops, slower current rise, and sharper decline in available peak power during cranking. In cold startups, internal resistance comprises electrode polarization, electrolyte viscosity effects, and contact resistances at terminals, all amplifying with lower temperatures. You quantify this by noting impedance growth at low frequency and increased charge-transfer resistance, which limit the instantaneous current the starter can draw. As ions struggle to migrate, the effective conductance of the electrolyte decreases, reducing the usable energy delivered within the few-second cranking window. You must distinguish true chemical resistance from wiring and connection losses, but the dominant factor remains internal resistance within the cell. Consequently, cold starts exhibit longer cranking times and greater starter current requirements. Understanding this role helps you target temperature management, electrolyte formulation, and material interfaces to mitigate poor cranking without conflating fuse behavior.

Why Fuses React Differently in Low Temperatures

Fuses don’t behave the same way in cold conditions because material and electrochemical processes slow down, shifting the balance of thermal and electrical effects that determine a fuse’s response. In low temperatures, conductor resistance rises, increasing heat generation thresholds needed for actuation, which can delay or suppress fuse triggering. You’ll observe altered fuse performance as current surges encounter higher cold resistance, forcing you to reassess protective margins and acceptable fault currents. The electrolyte impedance in polymeric or gel-based fuses stiffens, reducing ionic mobility and slowing reaction rates that normally drive rapid clearing. Packaging materials also contract differently, affecting contact pressure and thermal coupling to the ambient environment, which can create uneven heating and localized hotspots. Overall, low temperatures shift the equilibrium between self-heating and ambient cooling, changing timing, current at blow, and reliability. You should account for these shifts in spec sheets and safety margins to preserve consistent fuse performance under cold weather conditions.

Impact of Cold on Cranking Power and Starter Draw

Cold weather reduces chemical reaction rates and increases electrolyte viscosity in automotive starting systems, which directly lowers cranking power and raises starter current draw. You’ll observe a measurable drop in cranking efficiency as cold reduces available chemical energy per crank and slows electrode kinetics. Battery voltage under load collapses earlier, so the starter draws higher current to overcome friction and engine internals, yet delivers fewer impulses per second. The net effect is slower rotor acceleration and extended cranking times, often signaling marginal capacity or sulfation already present pre-winter. Starter performance becomes sensitive to state-of-charge, temperature, and internal resistance; even small temperature drops amplify resistance losses in cables, connectors, and the starter solenoid. In practice, you quantify effects by comparing cold-start current to warm-start baselines and monitor cranking speed at representative temps. Maintaining adequate cold-cranking amps, clean connections, and proper electrolyte balance supports cranking efficiency and sustains starter performance under cold conditions.

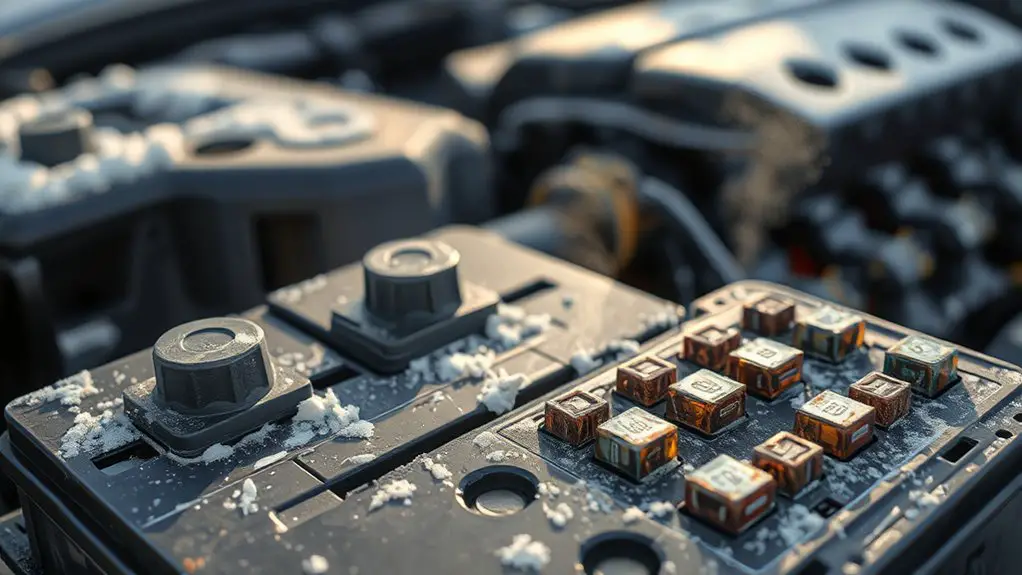

Common Symptoms of Cold-Related Battery Fuse Problems

As temperatures drop, battery fuse problems often surface through observable electrical symptoms rather than outright failures, so you’ll want to assess protection devices alongside the battery itself. In cold conditions, you may notice dimmer interior lights, slower accessory response, and intermittent gauges that spike or drop with cycle timing. A common signal is delayed starter engagement or a sluggish crank, even when the battery seems charged. Fuse-related issues often present as abrupt resets of radios or displays, or a faint click without full engine rotation. You might observe blown fuse indicators or a blown fuse warning precede a no-crank condition, especially after cold soak. Cold symptoms include increased resistance in fuse links, sounding a faint electrical chatter when systems try to draw current. If you detect repeated fuse failure during cold starts, inspect fuse blocks for corrosion, loose terminals, and heat-induced drift, and verify correct fuse ratings for the protection scheme.

Diagnosing Battery and Fuse Issues in Winter

Winter complicates diagnosis of battery and fuse issues, so start with a systematic checklist: verify battery voltage and cranking current at cold soak, inspect battery terminals for corrosion and tightness, and confirm fuse blocks are clean and properly seated.

In winter diagnosis, you focus on objective signals: voltage sag under load, parasitic drain, and fuse integrity. Document readings, compare to spec, and isolate stages: battery, connectors, and fuses. This approach emphasizes battery diagnosis and fuse troubleshooting as separate but linked tasks.

| Condition | Expected Reading | Action |

|---|---|---|

| Cold soak voltage | >12.4 V | Proceed to load test |

| Cranking current | >= 400 A (group size dependent) | Verify cable integrity |

| Terminal condition | Clean, tight | Reclean if needed |

| Fuse block | No corrosion | Replace if contact resistance high |

| Load test result | >9.6 V at start | Advance to system check |

This method preserves empirical rigor, enabling confident winter fault isolation and safe power delivery.

Practical Steps to Prevent Cold-Weather Problems

To minimize cold-weather battery issues, you should implement preventive battery care, including regular inspection, clean terminals, and proper charge maintenance. Employ warm-start techniques by preheating or planning starts to reduce peak load and aging, and store/operate the battery within recommended temperature ranges whenever possible. This discussion will outline practical steps for cold-weather maintenance, focusing on reliable charging practices, thermal management, and routine readiness checks.

Preventive Battery Care

Cold-weather battery performance hinges on proactive care; you can mitigate problems by implementing practical, proven steps. You’ll adopt disciplined battery maintenance routines: clean terminals, guarantee solid cable connections, and remove corrosion sources that impede current. Regular voltage checks reveal aging cells before failure; track cranking voltage and resting state to detect decline. Apply preventative measures like insulating the battery from extreme cold, mounting in a climate-controlled area when possible, and using a compatible, high-quality battery charger suited for low temperatures. Schedule periodic load tests and electrolyte level confirmations if you have a serviceable unit. Avoid short cycling and deep discharges; keep a refreshed spare on standby. Document procedures and results to optimize readiness, guaranteeing reliable starting performance across winter conditions.

Warm-Start Techniques

Even in frigid conditions, starting reliability hinges on practical warm-start steps that minimize internal resistance and electrolyte stratification. You implement targeted warm up strategies that reduce instantaneous current draw and voltage sag, preserving cranking torque. Begin by ensuring battery terminals are clean and snug; corrosion raises resistance, undermining ignition. Use moderate engine rotation after a brief idle to pre-heat the electrolyte without excessive parasitic load. Apply deliberate ignition techniques: quick, controlled cranks with brief rests to avoid coil overheating and fuel misfire, followed by a steady, measured ignition sequence. Monitor key indicators—state of charge, cranking voltage, and starter current—to determine when to extend warm-up. These steps maintain electrical economy, improve reliability, and support stable performance under cold-start stress.

Cold-Weather Maintenance

In cold weather, proactive maintenance minimizes performance degradation by targeting battery health and electrical system reliability. You should schedule regular battery voltage checks, inspect terminals for corrosion, and tighten clamps to minimize resistance. Keep your battery hydrated and clean; replace aging cells before they fail under load. During cold snaps, test cranking amperage and reserve capacity, noting any steep voltage drop. Confirm alternator belts are intact and drive belts aren’t slipping, since charging efficiency matters more when temperatures fall. Maintain appropriate cold-weather battery care by using a battery warmer or locating the vehicle in a sheltered, heated area when possible. Use engine oil with suitable viscosity for low temperatures to reduce startup strain. Document maintenance events and observe patterns to preempt reliability issues.

Mitigation Techniques for Emergency Cold Starts

Emergency cold starts require a structured sequence of actions to minimize battery strain and assure vehicle systems initialize reliably. You should prioritize predictable, repeatable steps that minimize cranking duration and prevent misfires. Verify that fuel, ignition, and electrical systems are configured for cold conditions before attempting start. If you must act, perform an orderly assessment: confirm battery voltage is within safe operating range, assure connections are clean and tight, and clear any frost or ice from essential sensors. In emergency jump starts, place donor and recipient vehicles at a safe distance, attach polarity-correct leads promptly, and avoid prolonged cranking after the first successful ignition. Cold weather preparedness hinges on timing and discipline: limit cranking to short bursts, allow a brief rest between attempts, and monitor electrical load to prevent alternator overload. Document repeatable procedures, train responders, and maintain equipment readiness to minimize failure risk and maximize start reliability under adverse conditions.

Long-Term Tips for Battery Health in Cold Climates

In cold climates, you’ll see Battery Temperature Decline influence both immediate performance and long-term health. You should monitor Charging Efficiency Loss trends and adjust charging strategies to minimize stress on cells. Implement a strict Routine Maintenance Cadence to detect early degradation and preserve capacity over multiple seasons.

Battery Temperature Decline

Cold-weather battery temperature declines over time due to reduced environmental heat input and internal resistance increases; this gradual drop can degrade capacity, reduce voltage stability, and slow reaction kinetics if not managed. You’ll observe lower charge acceptance and muted peak currents, revealing clear temperature effects on battery performance. In practice, temperature decline elevates internal losses, shifts open-circuit voltage, and narrows usable energy at cold states, reinforcing the need for monotonic monitoring rather than reactive fixes. Track core indicators: under-load voltage sag, cold-cranking amp limitations, and state-of-charge hysteresis as proxies for health. Mitigation should prioritize consistent thermal management, insulation quality, and rapid warm-up strategies before high-demand cycles. Emphasize empirical measurements, repeatability, and caution against extrapolating short-term results to long-term battery performance in variable cold environments.

Charging Efficiency Loss

Charging efficiency in cold climates declines as internal resistance rises and electrolyte kinetics slow, leading to higher parasitic losses during charging and lower net energy stored per unit input. You’ll notice charging speed drop with temperature, and energy density per cycle contracts as ions struggle to re-balance the electrode surfaces. To minimize impact, optimize current profiles and avoid aggressive charging when cold. Emphasize thermal management to sustain usable voltage windows and charge acceptance. In practice, small warm-up periods before charging preserve energy throughput and reduce degradation rates. Prioritize charging strategies that balance speed with efficiency, especially for high-demand cycles, to maintain usable capacity across cold seasons.

- Optimize charging profiles to balance charging speed and efficiency

- Maintain moderate electrolyte temperature to preserve energy density

- Time charging to leverage warmer periods and reduce parasitic losses

Routine Maintenance Cadence

Routine maintenance cadence matters because cold temperatures accelerate degradation pathways, so a disciplined, seasonal schedule helps preserve capacity and extend life. You implement routine inspections to catch corrosion, loose connections, and electrolyte imbalance before they impact cranking. Establish maintenance schedules that align with ambient lows, biasing checks at peak cold and during thaw shifts. Document voltages, cold-cranking amps, and parasitic draws, then compare against baseline measurements to reveal drift. Prioritize battery health with preventive actions: clean terminals, tighten fasteners, and verify alternator charging behavior under load. Use a concise log to trigger proactive replacements before failure risk rises. This disciplined cadence balances reliability with freedom, enabling you to maintain peak readiness without sacrificing autonomy. Regular cadence fosters data-driven decisions and minimizes unexpected cold-weather interruptions.

Frequently Asked Questions

How Do Fuses Differ From Batteries in Cold Starts?

A fuse isn’t a power source; in cold starts it protects circuits while you rely on the battery for juice. Fuses accommodate surges and prevent damage, but fuse functionality doesn’t supply cranking current. Battery performance governs cold-start ability, delivering amperage the starter requires. You might worry about protection limiting power, yet a healthy fuse remains intact as the battery falters. When temperatures drop, guarantee adequate battery capacity and monitor fuse integrity for reliable, precise starting.

Do Cold Temps Affect Fuse Types Differently Than Battery Capacity?

Cold temps can affect fuse types differently than battery capacity, but the impact is less about chemistry and more about design tolerances; cold fuse performance tends to be stable unless ratings approach their limits. Battery chemistry changes with temperature directly degrade capacity. You’ll see greater capacity loss in cold than fuse degradation, so fuses generally outlive ideal performance. In short, cold fuse performance is dependable, while battery chemistry changes drive cranking drops and reliability issues.

Can a Weak Battery Trigger Fuse Protection Prematurely?

Yes, a weak battery can trigger fuse protection prematurely. When battery health declines, internal resistance rises, causing higher current spikes and voltage dips that may trip protection thresholds. You’ll notice cranking struggles and potential fuse activation during peak loads. To minimize this, monitor battery health, reduce parasitic drains, and guarantee proper fuse sizing. Regular testing helps maintain reliable operation, especially in cold conditions where performance margins shrink and fuse protection engages earlier.

What Role Does Ambient Temperature Play in Starter Draw?

Ambient temperature directly influences starter draw: as temps drop, cold resistance rises, demanding higher current for the same torque. You’ll see reduced starter performance, slower cranking, and potentially premature fuse protection if the battery isn’t robust. In warmer conditions, resistance falls, easing draw. To optimize, guarantee strong battery health, clean connections, and consider heat-conditioning. Monitor ambient shifts, because even small temp changes can meaningfully alter starter performance and cold resistance.

Are Aftermarket Fuses Safer for Cold-Weather Cranking?

Aftermarket fuses can be safer for cold-weather cranking, but only if they’re quality-certified and properly rated. You’ll want aftermarket reliability that matches your system’s amperage and peak surge needs, plus fuse performance that remains stable as temps drop. In practice, choose weather-rated, automotive-grade fuses, verify OEM compatibility, and inspect connections. You’ll reduce misfires and unintended outages, while maintaining predictable current protection and quick response under cold-start stress.