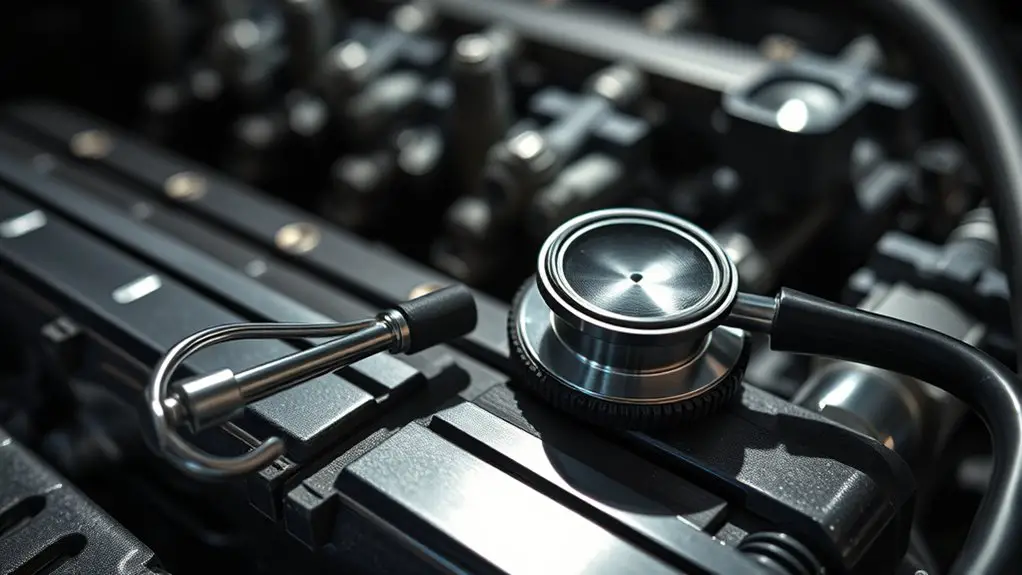

How to Use an Mechanic’s Stethoscope to Confirm an Engine Misfire Causing Emissions

To confirm an engine misfire with a mechanic’s stethoscope, start by safely setting up the tool and inspecting the probe, tubing, and ear pieces, then source a stable engine base at idle or a steady rpm. Listen near spark plugs to catch individual cylinder timing, near fuel injectors for discrete ticks, and along the exhaust for irregular pulse patterns. Compare findings to a baseline, link irregularities to specific cylinders, and correlate with emissions data; more detail awaits.

Assessing When a Stethoscope Is the Right Tool for Misfire Diagnosis

A stethoscope is a valuable first-step tool for misfire diagnosis when you need immediate, focused auditory information about engine-cylinder activity. In this situation, you assess whether listening will yield actionable clues before committing to more involved testing. You’ll consider engine behavior patterns, such as irregular cadence, dead cylinders, or unexpected transients, and judge if acoustic cues align with known misfire signatures. Diagnostic tools beyond sound—like spark, fuel, and compression checks—remain in reserve unless acoustic indicators clearly point to a specific cylinder. Your decision rests on the consistency of the audible events with the suspected fault and on ruling out benign noises from accessory drives or exhaust leaks. If the sounds correlate with misfire models and you can isolate a cylinder, the stethoscope supports a focused, data-driven approach rather than broad guesswork. When uncertainty persists, pivot to complementary diagnostic tools to confirm findings.

Safe Handling and Setup of a Mechanic’s Stethoscope

To guarantee accurate, safe use, start by selecting a clean, undamaged stethoscope and inspecting the probe tip, tubing, and ear pieces for wear or residue; replace or sanitize any compromised parts before use. You’ll set the device on a stable surface, avoid kinks in the tubing, and keep the headset aligned with your ears for a tight seal. Confirm battery or pneumatic function if your model relies on it, and test a short, low-noise click to verify response. Wear eye protection if working near the engine, and route cables away from heat sources, moving parts, and fluids. Maintain proper storage—keep components in their sheath or case when not in use. Document any calibration dates and perform routine tool maintenance after sessions to sustain accuracy. Emphasize proper usage and routine upkeep to minimize drift. Your goal: reliable feedback, repeatable results, safe handling throughout the diagnostic workflow.

Listening Techniques: Plugs, Injectors, and Exhaust Components

Listening for diagnostics starts with a structured approach to plugs, injectors, and exhaust components. You’ll locate the spark plug region and sample each cylinder’s ignition path by listening for crisp, individual timing cues rather than blended chatter. Focus on the spark plug for consistent ignition sound, noting any intermittent clicks that diverge from a steady rhythm. When probing fuel delivery, target the fuel injector area; a healthy injector produces a brief, sharp tick that aligns with the injector firing sequence. Compare multiple cylinders to establish a baseline, then identify deviations that suggest misfire potential. Exhale toward the exhaust manifold to hear muffled pulses and rhythm changes; a clean exhaust profile supports proper combustion. Maintain a calm, repeatable probe pattern, marking anomalies with time and location. Use the stethoscope’s bell for detail and the diaphragm for broader flow sounds, documenting findings for diagnostic correlation.

Interpreting Sounds to Identify Sustained Vs Intermittent Misfires

Interpreting sounds to identify sustained versus intermittent misfires requires a disciplined ear and a consistent reference baseline. You’ll train your stethoscope to isolate the exhaust note, spark events, and valve chatter, then compare each cylinder’s cadence against a stable, known good signature. Listen for a continuous, uniform irregularity that persists across multiple engine cycles—this indicates a sustained misfire. In contrast, transient disturbances that appear and vanish within a few firing events point to an intermittent misfire. Use a controlled idle and a steady rpm to establish baseline timbres, then elevate rpm to reveal cadence changes without fuel or ignition input changes. Document timing, duration, and the number of affected cylinders, noting whether the anomaly aligns with a single cylinder or shifts between banks. Focus on repeatability: true sustained misfires reproduce consistently under the same conditions, while intermittent misfires show irregularity. Your goal: precise identification without overinterpretation. sustained misfire, intermittent misfire.

Connecting Misfire Diagnosis to Emissions Readings and Catalyst Health

Connecting misfire diagnosis to emissions readings and catalyst health requires linking observed combustion irregularities to downstream effects. You’ll compare misfire timing, duration, and frequency with raw emissions data, noting spikes in hydrocarbons, carbon monoxide, and oxides of nitrogen that align with misfire events. Use your stethoscope findings to map which cylinders contribute most and correlate with slow responses on OBD data, then translate that into plausible catalyst loading scenarios. Track emission standards compliance by evaluating whether observed misfire-caused emissions exceed regulatory thresholds during test cycles, not just steady-state runs. Assess catalyst efficiency by considering how unburned fuel introduced during misfires can heat, saturate, or damage the substrate over time, reducing light-off performance and overall conversion efficiency. Document trends, repeatability, and any improvements when misfire is remedied. Preserve a methodical record to support diagnostic confidence and informed maintenance decisions.

Frequently Asked Questions

Can a Stethoscope Locate Misfires on Overhead Cam Engines?

Yes, you can use a stethoscope to help with overhead cam engines, but it’s not a guaranteed locator. You’ll listen for irregular tapping from misfire-adjacent cylinders and correlate with timing marks, fuel trims, and misfire detection data. Proceed methodically: verify cylinder balance, then sweep each valve train area while running. Don’t rely on it alone; combine mechanical listening with diagnostic codes and compression checks for accurate emissions-driven diagnosis.

How to Distinguish Bearing Noise From Ignition Misfire Sounds?

You can distinguish bearing noise from ignition misfire sounds by listening for continuous, rhythmic low-frequency knocks versus irregular, snapping ignition pops. Use bearing identification techniques like checking oil pressure, bearing play, and surface wear, and note that misfire sound characteristics are intermittent with RPM coupling. Isolate cylinders, observe harmonics, and compare with engine mapping. Maintain precise timing and stance, documenting deviations as you proceed, so you confidently identify the true source of the noise and your diagnostics stay lawful.

Do Stethoscope Readings Vary With Engine Load and RPM?

Yes, stethoscope readings vary with engine load and rpm. When you increase load or rpm, valve trains and fuel systems respond, shifting sounding patterns. You’ll notice louder, sharper ticks during higher rpm and when load climbs; lighter, subtler sounds at idle. Systematically compare at known loads, note timing of knocks, and correlate with engine speed. Use careful, repeatable measurements, documenting rpm effects and engine load to distinguish misfire-related noises from normal operation.

Can a Stethoscope Diagnose Vacuum Leaks Causing Misfires?

Yes, a stethoscope can aid vacuum leak diagnosis, but it isn’t definitive alone. You’ll listen for a hiss, intake manifold chatter, and abnormal engine rhythms while the engine idles and at steady rpm. Use it as a supplemental tool; verify with smoke tests or flow measurements. Be mindful of stethoscope effectiveness varies with engine design and noise. Document findings precisely, isolate suspected ports, then recheck after each corrective action.

Is There a Risk of Misinterpreting Exhaust-Turbo Noises as Misfires?

Yes, there is a risk of misinterpreting exhaust-turbo noises as misfires. You should distinguish between exhaust sounds from normal turbo operation and actual misfire indications by correlating stethoscope cues with engine RPM, sensor data, and cylinder-specific patterns. Use calm, systematic checks: listen for irregular pops, ping, or missing cycles, and verify with misfire counters. Focus on consistent turbo noise versus irregular exhaust sounds to avoid false conclusions about a misfire.