Cost and Labor to Fix EGR Valve Problems Involving Exhaust Heat Shield

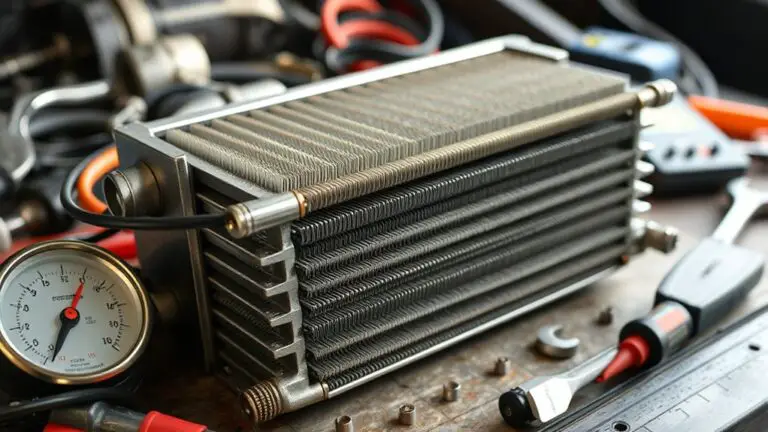

You’ll pay for EGR valve repairs that consider exhaust heat shield integrity, because shield condition directly drives service time, reliability, and safety. Expect labor to include shield removal, EGR inspection, possible valve replacement, gasket and fastener work, plus leak and safety tests. Spare parts vary: EGR valves ($60–$350), shields ($20–$120), gaskets and sensors extra. Plan…