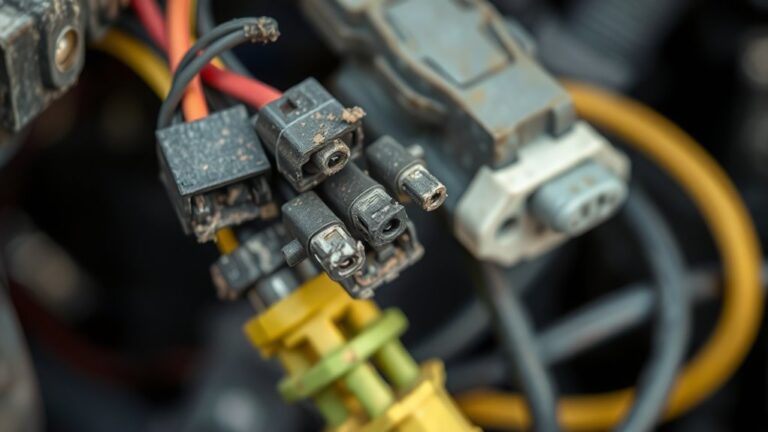

Cost and Liability Considerations When Repairing Data Bus Connector

When you repair a data bus connector, balance cost, liability, and reliability by conducting rigorous failure-mode analysis and applying standards-aligned procedures. Assess material compatibility, plating, and wire-harness density to guide tooling and process choices. Document each step, verify with thorough post-repair testing, and map data paths to prevent integrity issues. Consider repair versus replacement decisions,…