Preventive Checks to Stop Faulty Relays in Their Tracks

To stop faulty relays in their tracks, implement regular preventive checks. Focus on inspecting for overheating, insulation breakdowns, and contact wear. Utilize diagnostic tools for early detection and monitor relay performance. Establish a routine maintenance schedule based on usage patterns to minimize unexpected failures. Document all maintenance activities to track trends and issues. By staying proactive, you can enhance reliability and reduce costs. There’s much more to explore on maximizing relay efficiency and longevity.

Understanding the Role of Relays in Electrical Systems

Relays play a crucial role in electrical systems, as they function as automated switches that control various circuits. By understanding the different relay types, you can better appreciate their importance in maintaining the efficiency and reliability of your electrical systems. Electromechanical relays, solid-state relays, and hybrid relays each serve specific purposes, allowing for the seamless operation of electrical circuits.

When you integrate relays into your systems, you’re fundamentally creating pathways that enable high-voltage circuits to control low-voltage signals. This feature not only enhances safety but also grants you greater control over your electrical environment. Furthermore, different relay types can cater to diverse applications, from simple on/off functions to complex logic operations.

Common Causes of Relay Failures

Failures in relays can arise from several common causes that can compromise the functionality of electrical systems. One major issue is relay overheating, which often occurs due to excessive current flow or inadequate heat dissipation. When temperatures rise beyond acceptable limits, it can lead to insulation breakdown and eventual relay failure.

Another cause is contact wear. Over time, the mechanical and electrical stresses on contacts can diminish their effectiveness, resulting in poor connectivity and increased resistance. This degradation can create a feedback loop, further increasing the likelihood of overheating.

Additionally, environmental factors like humidity and dust can exacerbate these issues, leading to corrosion or short circuits. Identifying these common causes early on can help you implement preventive measures, ensuring reliable performance and longevity of your relays. By understanding these factors, you can maintain the integrity of your electrical systems and avoid unexpected downtimes.

Importance of Regular Inspection and Testing

Regular inspection and testing are critical for ensuring relay reliability and performance. Establishing a routine maintenance schedule and adhering to specific testing protocols can help you identify potential issues before they escalate. By prioritizing these practices, you can markedly reduce downtime and improve system efficiency.

Routine Maintenance Schedule

A well-structured routine maintenance schedule is essential for ensuring the reliability of relay systems. You need to establish an ideal maintenance frequency to prevent unexpected failures. Prioritizing tasks based on the criticality of each relay can enhance operational efficiency and reduce downtime. Regular inspections and documentation allow you to track performance trends, making it easier to identify potential issues before they escalate. When you implement a tailored maintenance schedule, you empower yourself to maintain control over the system’s integrity. Additionally, by remaining proactive, you can allocate resources more effectively. This approach not only enhances safety but also prolongs the lifespan of relays, ultimately contributing to a more resilient and efficient operation.

Testing Protocols Importance

While many may overlook the significance of routine testing protocols, consistent inspection and testing play a critical role in maintaining the reliability of relay systems. Establishing a proper testing frequency and effective protocol development can prevent costly failures and enhance operational efficiency.

| Testing Frequency | Impact on Reliability | Consequences of Neglect |

|---|---|---|

| Daily | High | Increased risk of failure |

| Weekly | Moderate | Reduced system performance |

| Monthly | Low | Possible long-term damage |

Recommended Preventive Maintenance Techniques

To guarantee ideal relay performance, you need a structured regular inspection schedule. Additionally, implementing precise component testing procedures will help identify potential issues before they escalate. By prioritizing these techniques, you can greatly reduce the risk of relay failure.

Regular Inspection Schedule

Establishing a regular inspection schedule is essential for maintaining the reliability of relays in any system. By adhering to a structured routine, you can prevent costly failures and guarantee peak performance. Consider the following aspects during your relay inspections:

- Maintenance Frequency: Set intervals based on usage and environmental conditions to guarantee timely relay inspection.

- Documentation: Keep detailed records of inspections to track performance trends and identify potential issues early.

- Team Training: Empower your team with the knowledge to recognize signs of wear or malfunction for faster response.

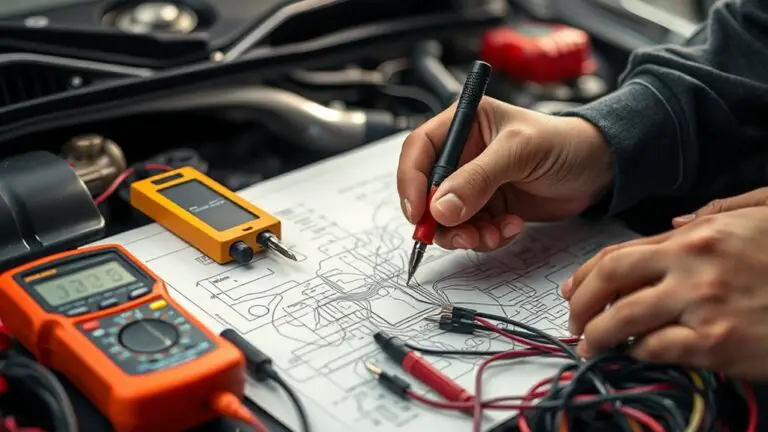

Component Testing Procedures

Effective component testing procedures are essential for ensuring the reliability of relays. You should regularly evaluate relay performance using specialized testing equipment to identify any potential issues before they escalate. Start with visual inspections to detect physical damage, followed by electrical tests that measure contact resistance and coil functionality. Utilize automated testing systems to streamline the process, ensuring accurate and repeatable results. Additionally, stress testing under various load conditions can provide insight into the relay’s durability. Document all findings meticulously to track performance trends over time. By adopting these methods, you’ll not only enhance the longevity of your relays but also maintain peak system functionality, granting you the freedom to operate with confidence.

Utilizing Diagnostic Tools for Early Detection

One key aspect of maintaining reliable relay performance is the early detection of faults through diagnostic tools. By employing advanced diagnostic software and real-time monitoring, you can identify issues before they escalate into failures. Here’s what you gain:

- Increased Reliability: Early detection minimizes the risk of unexpected downtime, guaranteeing your operations run smoothly.

- Cost Savings: Addressing faults early prevents costly repairs and replacements, safeguarding your budget.

- Enhanced Safety: Proactively monitoring relays reduces the risk of dangerous malfunctions, protecting your team and equipment.

Utilizing these tools empowers you to take control of your relay systems. You’ll not only enhance performance but also foster a culture of safety and efficiency. By making diagnostic tools a cornerstone of your maintenance strategy, you guarantee your relays are always operating at peak performance, ready to meet the demands of your operations.

Implementing a Routine Maintenance Schedule

A well-structured routine maintenance schedule is essential for guaranteeing the reliability and longevity of your relay systems. By implementing scheduled routine inspections, you can identify potential issues before they escalate into costly failures. This proactive approach not only enhances maintenance efficiency but also minimizes downtime, allowing your operations to run smoothly.

Start by defining the inspection frequency based on your system’s specific requirements and usage patterns. Regularly checking connections, testing functionality, and monitoring environmental conditions will guarantee peak performance. Documenting these inspections creates a valuable historical record, enabling you to track trends and make informed decisions about future maintenance.

Additionally, using checklists during these inspections helps maintain consistency and thoroughness. By prioritizing routine maintenance, you empower your team to take control of relay reliability, ultimately safeguarding your systems and enhancing operational freedom. Embrace this systematic approach to maximize the lifespan of your equipment.

Training Staff on Relay Maintenance Best Practices

Having established a routine maintenance schedule, the next key step involves equipping your staff with the knowledge and skills necessary for maintaining relay systems effectively. Training is essential for ensuring relay operation techniques are understood and applied correctly. Here are three strategies to enhance staff engagement:

- Hands-on Workshops: Provide interactive sessions that allow staff to practice relay maintenance in real scenarios, fostering confidence.

- Regular Knowledge Assessments: Implement quizzes and discussions to reinforce learning, ensuring staff stays updated on best practices.

- Feedback Mechanism: Encourage open communication where staff can share insights and challenges, creating a collaborative environment.

Documenting Maintenance Activities and Findings

While maintaining relay systems, documenting activities and findings is essential for tracking performance and identifying potential issues. You should maintain detailed maintenance logs that record every task performed, including inspections, adjustments, and replacements. These logs create a extensive history of each relay, making it easier to spot trends or recurring problems.

Regular findings analysis is vital. By reviewing documented data, you can pinpoint areas needing improvement or immediate attention. It’s important to include any anomalies discovered during maintenance, as this data can guide future strategies and preventive measures.

Make it a habit to update your logs immediately after each maintenance session, ensuring accuracy and reliability. This practice not only enhances your understanding of system performance but also empowers your team to make informed decisions. Ultimately, thorough documentation fosters a culture of accountability and continuous improvement in relay maintenance.

Upgrading to Modern Relay Technologies for Enhanced Reliability

Analyzing maintenance logs often reveals patterns that indicate the need for upgrades in relay technologies. Embracing modern relay technologies isn’t just about keeping up; it’s about achieving enhanced reliability for your systems. Here are three compelling reasons to evaluate this upgrade:

- Reduced Downtime: Modern relays offer quicker response times, minimizing interruptions and keeping your operations running smoothly.

- Improved Safety: Advanced technologies often include built-in diagnostics, enabling you to detect issues before they escalate, safeguarding both personnel and equipment.

- Cost Efficiency: Investing in reliable relays reduces maintenance costs over time, freeing up resources for other critical areas of your operation.

Frequently Asked Questions

How Can I Identify a Faulty Relay Quickly?

To identify a faulty relay quickly, you should start with relay testing using a multimeter. Check for continuity across the relay’s terminals when activated. If you’ve got diagnostic tools, utilize an oscilloscope to analyze the signal waveform. A distorted signal often indicates issues. Verify the relay’s coil voltage matches specifications; discrepancies can reveal faults. By systematically testing each aspect, you’ll pinpoint the problem efficiently and maintain operational freedom in your system.

What Are the Signs of Relay Deterioration?

You’ll notice several signs of relay deterioration as the average relay lifespan is about 10 years, depending on usage. Common relay symptoms include inconsistent operation, unusual clicking sounds, or overheating. You might also observe corrosion on terminals or burnt contacts, indicating wear. Regular monitoring can help you catch these issues early, potentially saving you from larger system failures. Staying vigilant guarantees your relays perform efficiently, maintaining the freedom of reliable operation in your systems.

Can Environmental Factors Affect Relay Performance?

Yes, environmental factors can greatly affect relay performance. Thermal effects can lead to overheating, which may cause contacts to weld or fail. Additionally, high humidity can introduce moisture, resulting in corrosion or electrical shorting. You should monitor these conditions closely, as they can considerably reduce relay lifespan and reliability. By understanding these impacts, you can take proactive measures to guarantee your relays operate effectively and maintain the freedom of your systems.

How Often Should Relays Be Replaced?

You should replace relays every 5 to 10 years, depending on their lifespan and usage conditions. A replacement schedule is essential to guarantee reliability and prevent failures. Regular inspections can help assess performance and identify any signs of wear. If environmental factors are harsh, consider more frequent replacements. Staying proactive about your relay maintenance can save you from unexpected downtimes and costly repairs, allowing you to maintain the freedom of efficient operations.

Are There Specific Brands of Relays Known for Reliability?

When it comes to reliable brands of relays, companies like Siemens and Omron often meet industry standards for performance and durability. Curiously, studies show that over 80% of industrial failures are linked to poor relay performance. By choosing trusted brands, you’re minimizing downtime and enhancing system reliability. You’ll find that investing in quality relays not only saves costs in the long run but also provides the freedom to operate smoothly and efficiently.