Top Causes of DPF Regeneration Problems

Top causes of DPF regeneration problems include soot buildup and saturation, which raise backpressure and disrupt regeneration cycles. Faulty or dirty EGR valves or leaks distort exhaust flow and heat management, while sensor malfunctions skew ECU feedback and trigger improper regenerations. DOC issues, restricted flow, and improper fuel-injection timing or poor atomization worsen soot generation. Defective regeneration temperature sensors and low exhaust flow from a restricted DPF compound the problem. Keep reading to uncover more factors and fixes.

Soot Buildup and DPF Saturation

Soot buildup is the primary driver of DPF saturation, reducing the filter’s porosity and increasing exhaust backpressure. You’ll notice diminished flow as soot accumulation fills the channels, stressing the exhaust system and altering performance. In this state, regeneration cycles become harder to initiate and sustain, and you may see longer intervals between recoveries. The core issue isn’t mystery; it’s improper combustion byproducts bypassing clean burn. Effective dpf maintenance hinges on controlling this accumulation at its source: fuel quality, injector timing, and combustion temperature all influence soot production and capture efficiency. You’ll optimize regeneration outcomes when you monitor soot loading with sensors and plan proactive cleaning before pressure rise indicates full saturation. Practically, schedule regular checks, calibrate fuel systems, and adopt maintenance routines that prevent excessive soot buildup. Remember: sustainable performance rests on timely interventions, precise diagnostics, and disciplined operation that respects the filter’s limits and your freedom to drive unencumbered.

Faulty or Dirty EGR Valve

A faulty or dirty EGR valve can disrupt exhaust gas recirculation, affecting emissions and DPF heat management. EGR valve clogging, leakage, and altered cooling performance directly influence soot handling and regeneration efficiency. Addressing these issues requires precise diagnostics to prevent recurring DPF problems.

EGR Valve Clogging

EGR valve clogging occurs when the valve becomes dirty or stuck, hindering exhaust gas recirculation and upsetting engine timing and emissions control. You’ll notice reduced MPG, rough idle, and potential misfires as flow is restricted. Diagnosing requires live data checks, not guessing. Focus on preventing buildup with targeted maintenance and reliable cleaning methods.

- EGR maintenance tips

- EGR cleaning methods

- Proactive inspection cadence

A rigorous approach keeps the EGR path clear, preserving turbo efficiency and combustion stability. Use compatible cleaners, avoid solvent overuse, and guarantee seals are intact after cleaning. When removal is needed, verify gasket integrity and valve seat sealing before reassembly. Monitor OBD data for EGR flow changes post-cleaning. If clogging recurs quickly, re-evaluate intake tract contaminants and fuel quality. Maintain a disciplined service interval to sustain performance and emissions compliance without sacrificing driving freedom.

EGR Leakage Issues

Leakage from a faulty or dirty EGR valve can allow exhaust gas to bypass the intended recirculation path, reducing control over EGR flow and upsetting oxygen sensor and turbo behavior. You’ll notice irregular EGR activity as the valve sticks or sticks partially open, altering intake charge and downstream sensor feedback. In EGR system design terms, the fault degrades planned dilution of NOx and can shift engine timing and fueling, triggering unexpected regeneration events or stalls. Accurate EGR leak detection hinges on pressure tests, flow measurements, and monitoring the ECU’s response to valve motion. When leakage occurs, you’ll see fluctuating boost pressure and inconsistent fuel trims, signaling a leakage path rather than a complete valve failure. Addressing the root cause restores predictable EGR scheduling and smoother DPF regeneration.

EGR Cooling Impact

As we shift from EGR leakage concerns, the focus now turns to how an EGR valve that’s faulty or dirty affects cooling and, in turn, the DPF regeneration process.

- EGR efficiency drops when carbon buildup or sticking restricts flow, raising exhaust temperatures that stress cooling paths.

- Dirty or malfunctioning valves degrade heat transfer, forcing the system to compensate and potentially prolong regeneration cycles.

- Regular EGR maintenance prevents erratic cooling behavior, preserving consistent exhaust temps and protecting DPF longevity.

In short, a compromised EGR valve disrupts cooling balance, undermines EGR effectiveness, and challenges DPF regeneration timing. You gain efficiency through meticulous EGR maintenance, reducing heat-related stress and preserving overall system performance.

Sensor Malfunctions and Fault Codes

Sensor Malfunctions and Fault Codes can derail DPF regeneration by halting emissions-control feedback and triggering unplanned cycles. You must treat sensors as the critical data input backbone; a single faulty signal cascades into repeated regenerations or complete stalls. Focus on sensor calibration to restore stable feedback loops, and conduct fault code diagnosis quickly to pinpoint root causes before replacing parts. When codes appear, you should cross-check with live data to differentiate sensor drift from wiring or connector faults. A disciplined diagnostic workflow minimizes downtime and preserves long-term performance.

| Category | Symptom | Action |

|---|---|---|

| Pressure | Inconsistent readings | Verify upstream/downstream taps; reseal connectors |

| Temperature | Unstable temps | Confirm sensor location; test with known-good unit |

| Electrical | Intermittent signals | Inspect harness, grounds; inspect for corrosion |

This approach keeps you in control, balancing precision with the freedom to troubleshoot boldly.

Diesel Oxidation Catalyst (DOC) and Catalyst Issues

Diesel Oxidation Catalyst (DOC) issues can undermine exhaust aftertreatment efficiency and trigger abnormal regeneration demands. You’ll correlate DOC performance with overall catalyst health, since degradation or contamination reduces oxidation reactions and shifts heat/pressure balance in the exhaust. When DOC efficiency wanes, you may see higher PM buildup downstream and erratic DPF cycles that complicate maintenance planning. Diagnostics should focus on flow resistance, temperature profiles, and oxygen storage dynamics, not just codes.

- Watch for fuel-derived contaminants and ash that blunt catalytic sites and reduce diesel performance.

- Monitor DOC temperature and light-off behavior to confirm timely activation and avoid unnecessary regenerations.

- Prioritize catalyst maintenance strategies that preserve substrate porosity and prevent bypass routes that undermine system efficiency.

Effective DOC management supports cleaner emissions, steadier performance, and predictable regen schedules. Maintain clear baselines, use quality lubricants and fuels, and verify catalyst integrity during routine servicing to sustain long-term diesel performance.

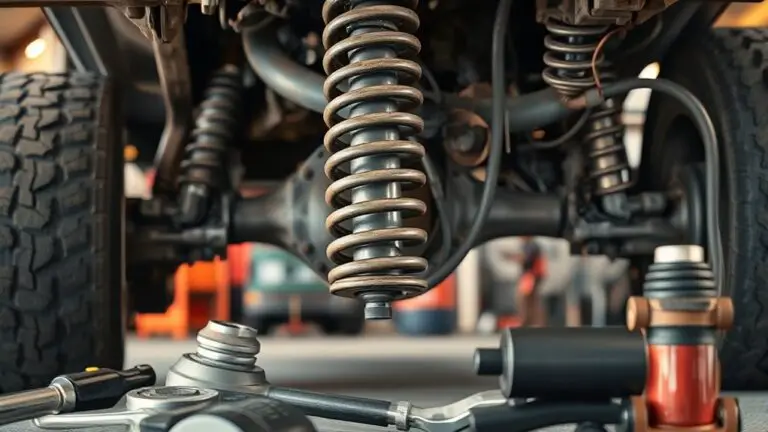

Exhaust Leaks and Poor Turbocharger Performance

Exhaust leaks and poor turbocharger performance directly undermine turbo efficiency and exhaust backpressure management, degrading engine breathing and aftertreatment heat balance. You’ll notice reduced flow control, inflated EGT variability, and inconsistent DPF regeneration. Leaks at hoses, gaskets, or connections disrupt pressure signals, leading to improper boost targeting and erratic fuel-air ratios. A compromised exhaust system also allows heat to escape, shifting thermal weight away from the DPF and raising soot aging risk. When turbocharger maintenance is neglected, compressor surge, impeller wear, and bearing play increase, worsening lag and reducing charging efficiency. In turn, exhaust gas temperature shorts change the oxidation and filtration dynamics inside the DOC/DPF, hastening fouling and prolonging regeneration cycles. Diagnostics rely on boost pressure trends, exhaust leaks tests, and turbine response assessments. Address leaks promptly, guarantee secure clamps, and maintain a clean, intact exhaust path to stabilize backpressure and preserve efficient regeneration.

Incorrect Fuel-Injection Timing and Poor Combustion

Mis-timed fuel injection disrupts combustion, reducing peak temps and increasing soot formation, which stresses the DPF regeneration cycle. You’ll see sensitivity to injector timing manifest as timing-related combustion loss, where small delays or advances degrade spray quality and combustion efficiency. This subsection also covers poor fuel-atomization effects and injector timing sensitivity, linking them to increased particulate loading and regeneration challenges.

Timing-related Combustion Loss

Timing-related combustion loss occurs when fuel-injection timing is off or the combustion process is inefficient, reducing exhaust gas temperatures and forcing more frequent DPF regenerations.

- combustion efficiency deviations raise heat loss and extend burn duration

- ignition timing errors shift peak pressure, lowering temps and increasing soot production

- diagnostic indicators point to mis-timed injections, elevated fuel consumption, and frequent regenerations

You’ll notice how small timing shifts degrade overall engine efficiency, forcing the exhaust to work harder and push the DPF into regeneration more often. In practice, precise timing restores combustion efficiency, stabilizes exhaust temperatures, and reduces regeneration frequency. If you ignore ignition timing issues, you’ll accumulate ash and catalysts that hinder flow. Remedy hinges on calibrated injectors, pump timing, and proper control-unit maps to maintain ideal combustion and minimize regeneration interruptions.

Poor Fuel-Atomization Effects

Poor fuel-atomization directly impacts combustion stability and exhaust temperature, increasing the likelihood of incomplete burning and soot formation. You’ll notice peaks in particulate load when spray breakup fails to achieve fine droplets, impairing fuel quality and mixing. This reduces combustion efficiency, elevates misfire risk, and raises backpressure on the DPF system. To mitigate, verify atomizer passages are clean, spray patterns are uniform, and injection pressure aligns with fuel-spec requirements. Monitor fuel quality and filtration to prevent wax or sediment ingress that disrupts atomization. Consistent atomization supports steadier heat release and more complete combustion, limiting soot generation and regeneration stress.

| Criterion | Effect |

|---|---|

| Fuel quality | Maintains spray consistency |

| Combustion efficiency | Reduces unburned hydrocarbons |

Injector Timing Sensitivity

Injector timing sensitivity directly governs combustion phasing; when fuel injects too early or too late, peak heat release shifts, elevating in-cylinder pressure fluctuations and increasing soot formation.

- injector calibration nuances can tilt timing, altering flame growth and soot propensity

- timing adjustments must balance power, efficiency, and emissions without destabilizing pressure cycles

- small deltas in injection timing amplify soot formation, degrading DPF performance over time

You’ll optimize by diagnosing fuel-system delays, injector wear, and rail-volume effects. Precision in calibration aligns spray plume with piston top dead center, improving mixture homogeneity and reducing unburnt fuel. Avoid aggressive timing shifts that provoke combustion knock or misfires. Track changes with in-cylinder pressure data, not just ECU logs. The goal is stable combustion, lower soot yield, and cleaner regeneration, achieved through disciplined injector calibration and measured timing adjustments.

Defective Regeneration Temperature Sensors

Defective regeneration temperature sensors can misreport exhaust gas temperatures, causing the emissions system to fail to initiate or extend the regeneration cycle when needed. You’ll notice skewed readings that distort the control logic, leading to incomplete burns or unnecessary activations. When sensor data drifts, the ECU may misjudge the soot load, triggering regeneration at suboptimal times or not at all, which increases fuel use and thermal stress. Temperature anomalies complicate fault diagnostics, since a single sensor can influence multiple subsystems, from dosing strategies to aftertreatment timing. Investigations should verify sensor calibration, wiring integrity, and heater function, as faulty sensors often exhibit intermittent behavior under heat soak or vibration. Prioritize cross-checks against reference temperatures and corroborate with live exhaust data. Corrective actions typically involve sensor replacement, harness repair, and ensuring proper shielding against EMI. Defective sensors, if left unchecked, degrade catalyst efficiency and raise the risk of failure thresholds.

Low Exhaust Flow Due to Tampered or Restricted DPF

Tampered or restricted DPFs can_create a noticeable drop in exhaust flow, compromising the system’s ability to sustain proper backpressure and heat balance. You’ll notice reduced exhaust flow leads to incomplete filtration, higher soot buildup, and more frequent regeneration triggers. The root cause is DPF restrictions that block flow paths, causing pressure differentials that the control logic misreads as demand for regeneration. Diagnosing requires careful inspection of inlet/outlet passages, sensor data, and potential tamper indicators rather than guessing on performance alone.

- Identify flow bottlenecks caused by tampering or improper ash removal

- Check for blockage-causing deposits and restricted catalyst channels

- Verify that exhaust flow sensors and differential pressure readings align with actual conditions

Keep your focus on measurable parameters: actual versus expected backpressure, temperature profiles, and ongoing fuel economy trends. If exhaust flow remains compromised, the system will struggle to sustain efficient regeneration, increasing emissions risk. Address restrictions promptly to restore DPF performance and maintain freedom in operation.

Infrequent or Short-Distance Driving Preventing Regeneration

Infrequent or short-distance driving prevents regeneration by failing to reach and sustain the high exhaust temperatures required for active DPF burn-off, causing soot to accumulate faster than it can be burned off. When you routinely drive short trips, the exhaust heat drops between public-safety pauses and idle periods, so the DPF never hits the critical temperatures needed to burn off particulates. This incomplete regeneration fosters ash buildup and increases the likelihood of clogging, which raises backpressure and fuel consumption. Your driving habits matter: longer highway runs raise peak temperatures, promote complete soot oxidation, and restore DPF efficiency more reliably. Regular patterns of brief starts and stops undermine a regenerative cycle and can lead to premature filter saturation. To mitigate risk, combine longer, steady drives with moderate engine loads and avoid prolonged idling. Monitoring your vehicle’s DPF status and adjusting driving behavior accordingly helps sustain performance, reduce regenerations, and preserve exhaust system integrity. short trips, driving habits.

Frequently Asked Questions

Can DPF Regeneration Be Manually Triggered by the Driver?

Yes, you can manually trigger a DPF regeneration, but it depends on your vehicle and firmware. Use manual regeneration techniques via the onboard menu or diagnostic tool, following manufacturer prompts. In your workflow, consider driver intervention methods like extended idle, highway runs, or controlled rpm boosts, but respect limits to avoid damage. This approach gives you control while preserving efficiency; monitor exhaust temps and pressure, and avoid forcing regeneration during critical loads or faults.

Do Certain Driving Patterns Permanently Damage the DPF?

You could say a DPF is like a stubborn toll booth, but not permanently blocked by normal use. No, certain driving patterns don’t permanently damage the filter, though repeated short trips, low-speed driving, or extended idling can reduce driving habits effectiveness. To protect filter longevity, you should vary speeds, complete regular regenerations, and avoid chronic low-speed operation. Your driving habits directly influence filter longevity, so stay proactive about highway runs and longer trips for peak performance.

How Long Does a Typical Forced Regeneration Take?

A typical forced regeneration lasts about 15 to 30 minutes, depending on vehicle and exhaust conditions. During this forced regeneration duration, you’ll see ECU prompts and elevated exhaust temperatures as the regeneration process overview unfolds. You should monitor gauges and listen for system messages; don’t interrupt the cycle unless safety is required. If it stalls, consult diagnostics, as delays point to sensor or injector issues rather than normal procedure. Stay proactive, guarantee proper fuel, and respect maintenance intervals.

Can Aftermarket Exhaust Components Affect Regeneration Reliability?

Yes, aftermarket components can affect regeneration reliability. If you install non‑OEM parts, exhaust flow can change, altering exhaust gas temperatures and sensor readings, which may trigger incomplete or failed regenerations. You’ll want to guarantee proper fit, materials, and backpressure management to avoid unintended holdups. Monitor EGT and O2 sensor signals, and validate that the system maintains sufficient heat for catalytic and particulate filter regeneration under real driving conditions.

Do DPF Problems Always Require Replacing the Filter?

Do you really think a DPF problem always means a new filter? Not necessarily. You might salvage it with proper filter maintenance and by addressing regeneration indicators early. Damage isn’t automatic—clogging, soot loads, or faulty sensors can be corrected before replacement. You’ll want a diagnostic check, cleanings if applicable, and software recalibration. If detection shows irreparable damage, replacement becomes sensible; otherwise, prevention beats part swaps every time.