When Garbage Odor in Cabin Suggest Bigger Electrical Issues

When you notice a garbage-like odor in the cabin, treat it as a potential alert for bigger electrical issues. Start by mapping the scent’s timing, intensity, and location, then inspect nearby panels for scorch marks, loose connections, or insulation damage. Use non-contact voltage tools first and power down nonessential circuits before any hands-on checks. If odor persists or escalates, escalate to a qualified technician and evacuate if you suspect overheating or arcing. More steps follow to guide you through safely.

Identifying the Source of the Odor

To identify the odor’s source, start with a systematic assessment of the cabin environment. You’ll map scents to zones, note timing, and record intensity. Begin with ventilation indicators: intake flow, filter condition, and recent changes in air quality. Next, inspect potential organic contributors: kitchen waste, spoiled cargo, or damp textiles that can emit volatile compounds. Trace the odor to its strongest concentration while maintaining a calm, methodical approach. Use a targeted sniff protocol—move gradually from doorway to aft, documenting shifts in aroma strength. Differentiate persistent, source-bound smells from transient plumes that dissipate with air exchange. Consider whether the odor aligns with known odor sources or if it presents as unfamiliar or chemical—this guides further investigation. Maintain a log of observations, environmental conditions, and potential correlates. Your goal is accurate smell identification that informs safe, decisive actions without unnecessary disruption.

Common Electrical Causes Behind Bad Smells

Electrical odors often stem from components overheating, arcing, or insulation breakdown. You’ll examine systems methodically to identify the primary culprits without guessing. First, inspect electrical insulation for signs of heat damage, cracking, or melted coatings; degraded insulation is a common source of odor and risk. Next, assess wiring deterioration: brittle insulation, frayed conductors, or loosened connections can create resistance, heat, and off-gassing odors that mimic spoiled cargo. Pay attention to junction boxes and harnesses where aging materials collect dust and moisture, accelerating deterioration. Look for loose terminals, corroded fasteners, or overloaded circuits that force equipment into unsafe operating temperatures. Use targeted tests to confirm abnormalities rather than relying on smell alone. Document findings with diagrams and measurements, and prioritize repairs that restore safe thermal profiles. Remember, timely remediation reduces fire risk and clarifies whether an odor stems from insulation faults or wiring wear.

Distinguishing Normal Cabin Smells From Electrical Issues

You’ll compare typical cabin odors to electrical cues, noting that normal smells come from routine sources and don’t change over time. Look for signs of electrical anomalies, such as new warmth, persistent burning, or unusual concentrations that accompany odor. Use objective checks to distinguish normal odor patterns from potential electrical issues, and escalate if any anomaly persists or alters character.

Normal Vs Electrical Odor

In a cabin, distinguishing a normal odor from an electrical issue hinges on identifying consistent, repeatable patterns. You assess duration, intensity, and onset: normal smells tend to be familiar, transient, and linked to routine activities; electrical smells are persistent, unusual, and tied to specific components or heat indicators. Note sources: food, cleaning agents, or mildew may create predictable, non-harmful aromas, whereas electrical smells often carry metallic, hot-plastic, or ozone-like notes. Temperature or airflow changes can modulate both, but electrical smells typically intensify near outlets, panels, or electrical devices, warranting inspection. Document frequency, location, and trigger events; compare to baseline cabin odor experiences; use caution with any new, non-normal scent. If in doubt, isolate power and consult qualified personnel. Normal smells remain benign; electrical smells demand scrutiny.

Detecting Electrical Anomalies

A careful approach to distinguishing normal cabin smells from electrical issues starts with a clear baseline and repeatable checks. You establish normal odor fingerprints, airflow patterns, and electrical load behavior during calm operations. When a deviation appears, you conduct structured checks: verify system status indicators, listen for intermittent arcing or buzzing, and measure voltage, current, and insulation temperatures with calibrated tools. Compare readings against documented tolerances and historical trends, noting time correlation with cabin activities. You document anomalies precisely, including location, odor characteristics, and duration. You assess potential sources, prioritizing safety and rapid isolation if symptoms escalate. Detecting anomalies relies on disciplined observation and data; identifying hazards triggers escalation plans and corrective actions. Your method preserves performance, mitigates risk, and supports informed decisions under pressure.

Early Warning Signs of Wiring Overload

Overloading electrical circuits can manifest through distinct early warning signs that you can spot before a failure occurs. You should monitor for warmth around outlets, switches, and cords, and note any buzzing or crackling noises that accompany use. Repeated tripping breakers aren’t random; they signal sustained demand exceeding capacity. Dim or flickering lights indicate voltage drop under load, a clue you shouldn’t ignore. If plugs or cords become warm to the touch, or you notice scorch marks, treat them as urgent indicators of potential overload. Extension cords used for high-wemand devices deserve scrutiny; misplaced, frayed, or taped connections raise risk. You’ll also observe unusual sparking at receptacles during insertion or removal, a clear overload symptom that warrants immediate attention. Maintain clear pathways and proper load distribution to uphold wiring safety. Document patterns of high-use devices and avoid daisy-chaining. Staying proactive minimizes risk while preserving the freedom to operate without fear of cascading electrical faults.

Steps to Safely Inspect Electrical Panels and Outlets

You should start by noting any unusual smells near panels or outlets, as scent clues can indicate overheating or insulation damage. Inspect with the power off, verify circuit labeling, and look for scorch marks, loose connections, or signs of wear before handling components. If you detect a smell or sight abnormalities, pause, isolate the area, and consult a qualified electrician for safe inspection steps.

Inspect for Smell Clues

In order to assess potential electrical issues, start by carefully smelling for unusual odors around panels and outlets, noting any hint of burning, hot insulation, or ozone. You’ll perform odor detection with deliberate, controlled inhales and focused attention, avoiding distractions. Move slowly along each access point, keeping distance consistent to compare across locations. If you detect sweet, acrid, or chemical notes, log time, location, and intensity, then mark suspected hotspots on a mental map. Practice smell identification by correlating odors with potential causes—overheating contacts, loose connections, or arcing. Do not touch energized components; use only approved tools and PPE. Document findings concisely, and decide if professional evaluation is warranted. Prioritize safety, repeat observations, and maintain a calm, methodical approach.

Safe Panel Handling Steps

Safe panel handling starts with preparatory precautions: make certain the area is dry, turn off the main power if accessible, and verify a de-energized state before touching any components. You approach with calm, deliberate steps, documenting each action. Before opening a panel, inspect for signs of moisture, corrosion, or burn marks to meet panel safety expectations. Use proper electrical precautions: wear insulated gloves, keep tools nonconductive, and avoid metal jewelry. Work one side at a time, never forcing a stuck breaker, and test voltage with a calibrated tester.

| Zone | Condition | Action |

|---|---|---|

| Floor | Wet | Dry and de-energize |

| Panel | Dusty | Clean gently |

| Breaker | Loose | Secure firmly |

| Contacts | Discolored | Inspect replace |

| Door | Damaged | Do not use |

When to Shut Off Power and Evacuate

If a hazardous odor is detected in the cabin, shut off electrical power to nonessential systems only after ensuring you can do so safely, then evacuate immediately if conditions worsen or you cannot confirm the source is non-threatening. You’ll follow emergency procedures with calm, deliberate steps, prioritizing personal safety and crew accountability. Locate a safe, immediate exit path and activate any accessible alarm or notification mechanism as you depart. Do not attempt to isolate the issue from within a confined space if you feel compromised or the odor intensifies. Once evacuated, establish a muster point, verify everyone is accounted for, and await professional assessment. Do not re-enter until authorities declare it safe. During the incident, document observable conditions succinctly for responders, including odor intensity and affected areas. Maintain clear radio communication, update safety protocols, and review lessons learned to prevent recurrence while preserving operational readiness and personal freedom.

How to Test for Electrical Faults Without Risk

Testing electrical faults without risk starts with a controlled, non-contact approach that minimizes exposure to energized components. You begin by inspecting the system layout and verifying de-energization status with a non-contact detector to confirm absence of hazardous voltage signs before any hands-on work. Next, establish a safe work perimeter, using lockout/tagout practices where applicable, and document observed conditions. For circuit testing, rely on insulated tools and low-touch techniques to check continuity, insulation integrity, and component accessibility without triggering equipment. When you perform voltage measurement, use a calibrated multimeter or non-contact tester to confirm standby voltages, alerting you to hidden energization or fault-induced leakage. Record readings systematically, noting time, location, and test method. Maintain a controlled environment, avoid capacitive discharges, and replace any damaged protective gear before proceeding. If readings indicate anomalies, isolate the affected circuit and re-test to corroborate findings before any remediation, ensuring progress remains deliberate and safe.

Choosing a Qualified Electrician for Diagnosis

Choosing a qualified electrician for diagnosis starts with confirming credentials, experience, and scope of expertise relevant to your system. You’ll want a technician who can translate symptoms into a precise fault map, not guesswork. Focus on proven qualifications and demonstrated electrician experience, paired with project relevance to your layout and power load. A disciplined approach reduces risk and clarifies next steps without unnecessary downtime.

Choosing a qualified electrician ensures precise fault mapping, not guesswork, with clear scope, experience, and transparent deliverables.

- qualifications checklist to verify licenses, insurance, and ongoing training

- documented electrician experience with systems like yours

- clear description of diagnosis scope and limits of responsibility

- references from similar installations and outcomes

- transparent pricing, timelines, and diagnostic deliverables

Preventive Measures to Reduce Future Odor and Faults

To minimize future odor issues and related faults, implement a structured preventive plan that combines routine maintenance, systematic monitoring, and fast-response protocols. You’ll adopt a lifecycle mindset: schedule preventive maintenance windows, log findings, and verify corrective actions. Use routine inspections to establish baseline signatures for electrical components, seals, and air pathways. Prioritize early detection by integrating sensor data, thermal imagery, and odor-forecast cues into a single dashboard, with clear thresholds for alerting. Standardize cleaning procedures to prevent residue buildup that accelerates degradation and odor formation. Define fault-handling playbooks that specify immediate isolation, voltage checks, and component replacement steps, minimizing downtime and risk. Train crew members to follow checklists, document deviations, and pursue root-cause analysis after any odor event. Continually review performance metrics, adjust maintenance intervals, and verify safeguards. This disciplined approach sustains system reliability while preserving the sense of freedom you value in operating conditions.

Frequently Asked Questions

Can a Lingering Odor Indicate Hidden Electrical Fires?

Yes, a lingering odor can indicate hidden electrical fires, so don’t ignore it. You should act promptly: stop using affected systems, ventilate, and isolate the source. Check for warm panels, buzzing or scorch marks, and unusual smoke. Call a licensed electrician to assess with proper odor detection and electrical safety protocols. Don’t assume it’s benign—risks escalate quickly as insulation and wiring degrade. Your caution protects you and others from potential fire and harm.

Should You Evacuate Before Calling for Help?

Yes, you should evacuate first, then call for help. Picture a flow: detect risk, separate variables, initiate emergency protocols, alert others, and move to safety. You verify conditions from a distance, avoid re-entry, and don’t delay if odor or smoke persists. Safety measures require you prioritize life over property. Once at a safe distance, report specifics—location, odor intensity, signs of fire. Stay calm, document, and follow official instructions.

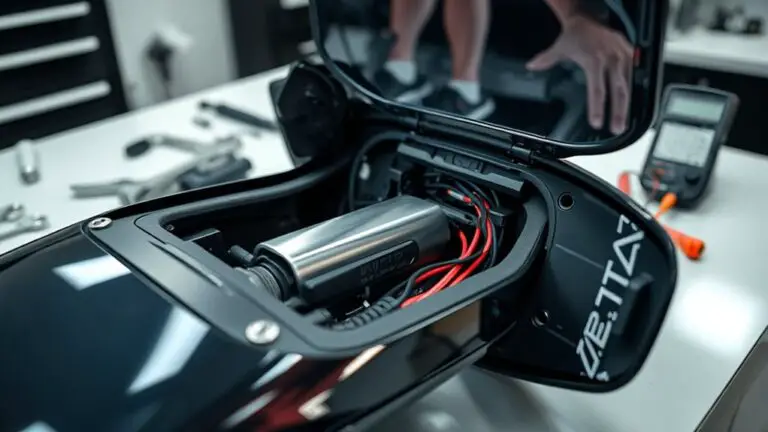

Can Battery Packs Cause Similar Smells in Cabins?

Yes, battery packs can cause similar smells in cabins. If you notice an acrid or sulfurous odor, treat it as a potential battery malfunction and investigate odor sources promptly. You should isolate the pack, avoid contact with liquids, and ventilate the area while you assess heat buildup, swelling, or smoke. Do not ignore warning signs; replace damaged cells, follow manufacturer guidance, and consult trained personnel for a safe, methodical resolution.

How Accurate Are DIY Odor Tests for Electrical Faults?

DIY diligence debunks danger: DIY methods aren’t highly accurate for electrical faults. You should treat odor tests as preliminary, not definitive, and rely on professional diagnostics for certainty. If you suspect trouble, document signals, use calibrated tools, and isolate power safely. Odor detection may hint at overheating or chemical release, but it’s not proof. You’re free to explore, yet proceed cautiously, approachfully, and promptly seek licensed inspection when alarms arise.

What Immediate Steps if You Suspect a Main Panel Fault?

If you suspect a main panel fault, stop, and prioritize safety. Immediately shut off the main disconnect if you can do so without risk, then evacuate others and call emergency services if there’s any fire or strong burning odor. Do not touch exposed conductors. Document electrical fault signs, inspect for overheating, buzzing, or arcing sounds, and keep clear. Once vetted, avoid powering up; contact a licensed electrician for main panel safety assessment and repairs.