Why Battery Thermal Management Issue Appear After Charging and How to Fix Them

You’ll see battery thermal issues after charging because rapid charging and charge-transfer heat raise internal resistance losses faster than they can dissipate. This signals the need for better cooling, smarter charging, and proactive maintenance. Heat spikes come from high charging currents, chemistry limits, and uneven heat distribution. Manage with slower, stage charging, improve airflow, and verify thermal interfaces. Regular sensor checks, prepared maintenance, and automated alerts help prevent hotspots. If you keep going, you’ll uncover how to optimize protection and performance.

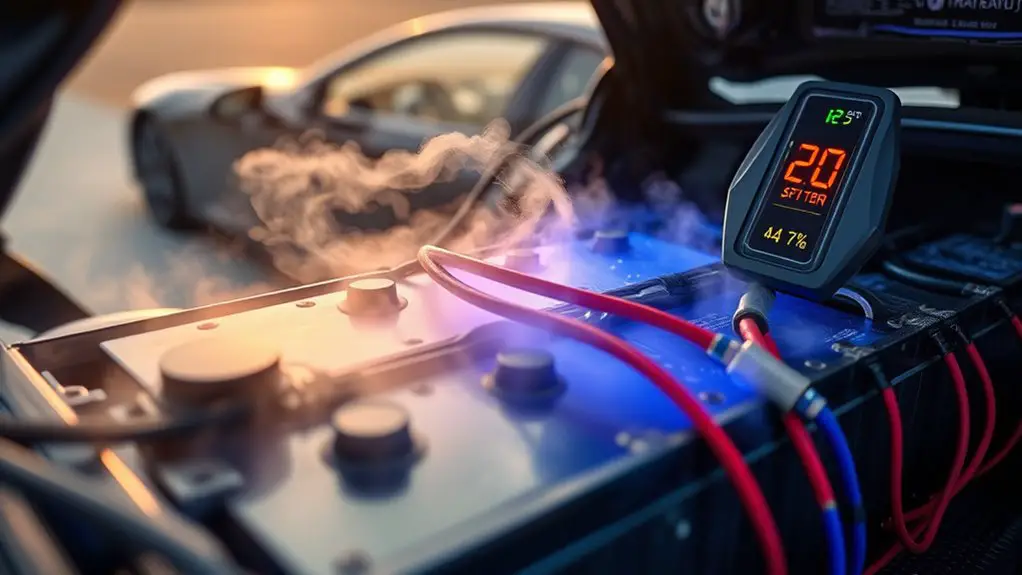

What Causes Temperature Spikes After Charging

Charging can produce temperature spikes due to the rapid influx of energy and the accompanying internal resistance losses. As you begin charging, the battery experiences a surge that raises internal heat faster than it can be dissipated. This spike is influenced by battery chemistry choices, electrode materials, and state of charge. Temperature regulation mechanisms respond to this transient with varying efficiency depending on design and ambient conditions. You’ll see higher instantaneous heat in chemistries with larger overpotential, where reaction kinetics generate more energy as charge transfer proceeds. Conductive paths, contact resistance, and electrolyte viscosity also contribute, converting electrical energy into heat rather than stored chemical energy. Rapid charging intensifies these effects, stressing protective thermistors and cooling loops. Understanding these dynamics helps you predict when cooling capacity is insufficient and when to adjust charging rates. In practice, optimize timing, monitor temperature feedback, and align charging profiles with battery chemistry to maintain safe, stable operation.

Common Signs of Post-Charge Thermal Issues

After charging, you may notice a distinct set of thermal patterns that indicate lingering or delayed heat generation. Common signs include localized warmth near the pack, uneven surface temperatures, and prolonged elevated core temps after the device rests. You may also detect lingering fan activity or cooler-then-warm cycling, suggesting late dissipation. Battery performance may degrade temporarily, with reduced response time or subtle voltage drift. Thermal sensors often reveal staggered readings that don’t match expected baseline behavior, signaling delayed heat release. Persistent heat generations could accompany creaking or soft-pack deformation in extreme cases. If you trust the data from firmware alerts, treat slight but repeated anomalies as measurable indicators rather than noise. Regular monitoring helps you distinguish post-charge quirks from ongoing problems, ensuring safer operation and informed maintenance decisions.

| Symptom | Indicator |

|---|---|

| Localized warmth | Warm spot near pack surfaces |

| Uneven temps | Inconsistent thermal map readings |

| Prolonged core heat | Elevated core temps post-charge |

| Sensor drift | Temperature readings diverge over cycles |

| Fan activity | Unnecessary aftercooling signals |

How Charging Routines Affect Heat Buildup

Efficient heat management hinges on charging routines, because the way you pace, monitor, and terminate charging directly shapes heat generation and dissipation. Your charging speed directly influences instantaneous heat output, while longer, slower cycles reduce peak temperatures but extend exposure. The balance between fast top‑ups and battery cycles matters: aggressive charging can spike internal resistance heating, degrading thermal margins over multiple cycles. Conversely, conservative routines preserve material integrity, yet demand patience and disciplined monitoring. The goal is to align charging endpoints with thermal capacity, avoiding sudden current surges that trigger runaway heat pockets. Implementing stepwise current reductions, temperature‑aware cutoffs, and consistent SOC targets helps keep heat within safe envelopes across battery cycles. Precision in timing, measurement, and parameterization yields predictable thermal behavior and extends usable life without sacrificing performance.

- You feel the sting of heat spikes when speed wins over control

- Every high‑power pause reshapes the next cycles’ heat profile

- Small, deliberate adjustments compound into steadier temperatures

- Freedom to optimize demands with disciplined, data‑driven routines

Cooling Improvements to Prevent Heat After Charging

Post-charge cooling zones must be implemented to promptly remove residual heat, preventing hotspots that can accelerate degradation. Efficient heat dissipation methods should be evaluated for their impact on cycle life, charging speed, and thermal uniformity across cells. This discussion will compare zoning strategies and practical cooling architectures to optimize post-charge thermal stability.

Post-Charge Cooling Zones

To prevent heat buildup after charging, post-charge cooling zones deploy targeted airflow and cooling cycles that continue once charging completes, ensuring residual heat is removed before operating at peak loads. These zones balance post charge ventilation with strategic thermal insulation so heat recedes quickly while staying contained. By sequencing mild to moderate airflow after cessation of charging, you avoid temperature spikes that degrade cells and pack interfaces. Monitoring sensors validate when temperatures align with safe baselines, allowing a deliberate shift to normal operation. The approach minimizes thermal lag, reduces peak stress, and preserves battery life. It also supports user freedom by offering predictable performance without abrupt thermal throttling.

- Consistent, quiet airflow that feels reliable

- Clear indicators of when to resume full power

- Visible safeguards around heat pockets

- Confidence in long-term pack integrity

Efficient Heat Dissipation Methods

Effective heat dissipation after charging hinges on optimizing airflow, material thermals, and control strategies to prevent residual heat from elevating cell temperatures during subsequent high-load periods. You implement efficient heat paths by balancing passive cooling and active cooling, selecting materials with low thermal impedance, and aligning venting with expected duty cycles. Passive cooling leverages natural convection, surface fins, and phase-change surfaces to shed heat without power draw. Active cooling adds controllable elements—fans, micro-pumps, or thermoelectric modules—triggered by real-time sensors to maintain safe temperature margins. You design for minimal thermal lag between charging and high-load phases, use predictive control, and guarantee redundancy. The result is stable temperatures, preserved cycle life, and freedom from overcooling penalties while maintaining performance.

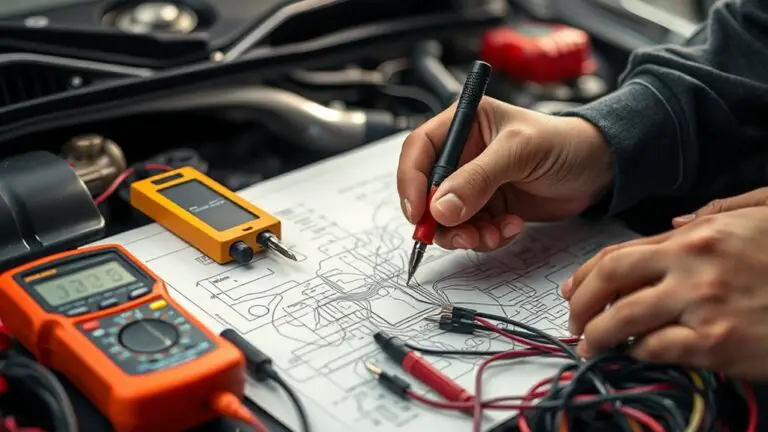

Selecting Gear and Settings for Safer Charging

Selecting gear and settings for safer charging starts with choosing components and configurations that minimize heat generation and venting risk while maximizing monitoring fidelity.

You’ll optimize gear selection and charging settings to reduce thermal load: pick high-fidelity sensors, robust BMS, and cooling-friendly enclosures; favor components with proven thermal margins and efficient power conversion; configure charge rates that align with cell chemistry and pack temperature envelopes. Tighten control loops, implement aggressive early-stage monitoring, and set conservative thresholds that preempt runaway conditions. Prioritize modular, replaceable parts to sustain long-term reliability while keeping the system agile for upgrades. Balance autonomy with supervision so you retain decisive oversight during deviations from norm.

- Precision sensors that translate heat into actionable signals

- Conservative charging settings that favor safety over speed

- Clear fault pathways with immediate, visible alerts

- Flexible gear selection enabling rapid adaptation

This approach preserves freedom while enforcing rigorous safety discipline.

Safe Maintenance and Monitoring Practices

Regular maintenance and vigilant monitoring are essential to preserve thermal control and detect deviations before they escalate, especially as pack temperature envelopes shift with aging and cycling. You should implement a structured routine that prioritizes preventive measures and consistent data collection. Schedule preventive measures like coolant level verification, sensor calibration checks, and thermal interface inspections after every significant cycle or heat event. Maintain logs of temperature, current, voltage, and ambient conditions to identify subtle trends that precede faults. Establish routine checks for insulation integrity, connector torque, and fan or pump performance to prevent localized hotspots. Use standardized checklists to minimize omissions and enable rapid root-cause analysis when anomalies appear. Automate alert thresholds for over/under-temperature, rapid deltas, or degraded cooling capacity, and validate corrective actions with post-maintenance tests. Finally, train operators to recognize deviations, document interventions, and uphold disciplined maintenance to sustain safe, reliable operation.

Frequently Asked Questions

Can Battery Heat Spikes Occur During Fast Charging Only?

Yes, heat spikes can occur during fast charging, but they’re not limited to it. You’ll see them when the battery’s internal resistance rises, charging current is high, or ambient temps are hot. As you push fast charging, watch for peak temperatures that briefly exceed safe thresholds. If you notice frequent heat spikes, you may need to adjust charge limits, improve cooling, or optimize battery health to maintain performance and safety.

Do Ambient Temperatures Affect Post-Charge Temperatures Differently?

Ambient temperature effects do influence post-charge temperatures; hotter ambient air slows cooling and can elevate battery surface temps after charging. You’ll notice higher peak temps and longer cooldown in warm environments, while cooler surroundings aid faster post-charge cooling. You should monitor ambient conditions because they alter thermal management needs. This isn’t about charging speed alone; it’s about how ambient temperature affects heat dissipation, thermal inertia, and your battery’s safe operating window.

Can Software Updates Alter Charging Heat Generation Patterns?

“Like clockwork,” you ask whether software updates can alter charging heat generation patterns. Yes, they can. Updates may adjust charging algorithms, modulation ramping, and thermal sensing thresholds, changing heat profiles during charge. This affects thermal management by shifting peak temps and duration. You’ll notice different heat behavior post-update, requiring recalibrated cooling strategies and monitoring to maintain safe operation while preserving charging efficiency and battery longevity.

Are There Battery Chemistries Less Prone to Post-Charge Heating?

Yes, some chemistries are less prone to post-charge heating. You’ll find that lithium phosphate and nickel manganese chemistries typically exhibit lower thermal runaway risk and steadier heat profiles during/after charging, compared to high-energy lithium nickel cobalt formulations. You’ll benefit from conservative charging, proper thermal design, and system monitoring. In practice, choose lithium phosphate for stability and nickel manganese blends for balanced energy and temperature, while avoiding aggressive C-rates that spike heat.

Should I Disconnect Devices After Charging to Cool Faster?

Yes, you should consider disconnecting devices after charging to cool faster. You might object that it’s impractical, but mindful charging habits reduce thermal buildup and extend battery life. By disconnecting devices, you prevent constant trickle cooling and lingering heat. This drops peak temperatures and stabilizes performance. In routine terms, integrate charging habits that favor short, complete sessions, monitor temps, and unplug promptly when full. You gain efficiency, reliability, and the freedom to push your devices harder later.