How Thermal Issues in Pre-Charge Resistor Cause Loss of Power in EV Mode and Fixes

Thermal buildup in pre-charge resistors raises resistance and dissipated power when you connect the high‑voltage bus, throttling EV charging current and overall power delivery. As heat fills the resistor, efficiency falls and battery charging slows, especially during fast changes. You fix this with proper sizing, targeted cooling, and duty cycling to limit peak stress. Real‑time temperature sensing helps halt overload before damage. If you keep exploring, you’ll uncover concrete steps to sustain performance under varying conditions.

Understanding Pre-Charge Resistors in EV Systems

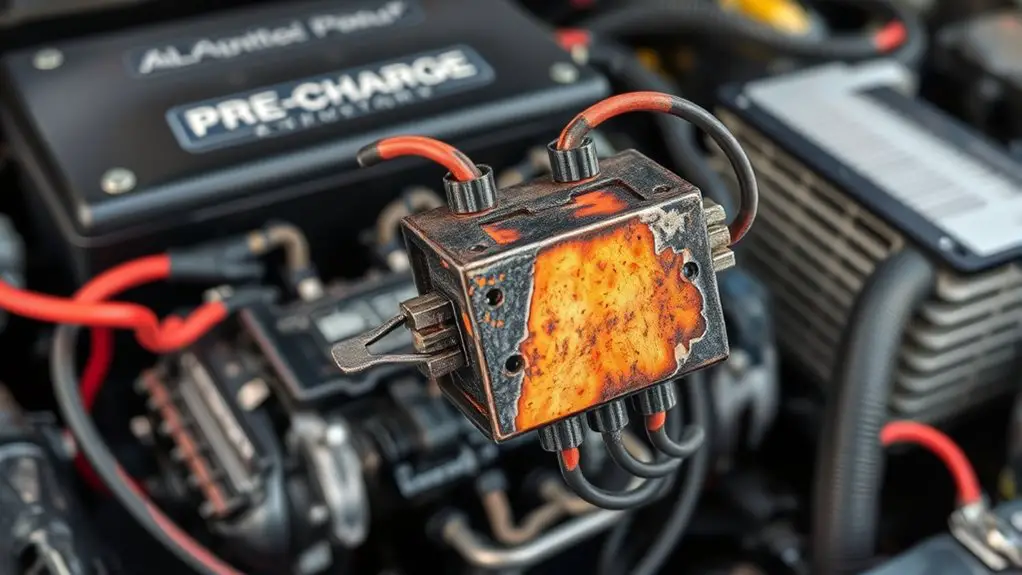

Pre-charge resistors in EV systems are simple but essential components that limit inrush current when connecting the high-voltage DC bus to the system. You’ll see them quietly performing a controlled wake-up, preventing voltage spikes that could damage components or fuse links. In understanding pre-charge functionality, you focus on timing, resistance values, and duty cycles that suit your pack voltage and available current. You’ll select resistor types based on environment, power, and thermal rise, balancing size, cost, and reliability. Ceramic and wire-wound types offer distinct profiles: ceramics for compact, high-stability paths; wire-wounds for higher power handling with robust heat dissipation. You’ll monitor safe operating area and peak dissipation to avoid nuisance trips. In practice, you document selection criteria, test brief inrush behavior, and verify that the path returns to steady-state quickly without excessive voltage drop. Clarity guides you toward dependable, freedom-loving EV performance.

Why Thermal Buildup Occurs During EV Mode Transitions

When an EV shifts from idle to active running, the pre-charge path experiences abrupt changes in current, voltage, and duty cycle. This sudden shift creates transient heat generation as the circuit responds to changing impedance and charging demands. You’ll notice that thermal buildup accumulates where current spikes are highest, and where charge redistribution concentrates energy. The result is localized heating that tests thermal conductivity and the capacity of resistor materials to absorb and dissipate energy without sagging in performance.

To understand and manage this, focus on these factors:

1) How peak currents align with resistance values and material properties, influencing heat generation.

2) The role of thermal pathways, including heatsinks and ambient cooling, in preventing buildup.

3) Material quality and stability of resistor materials under rapid, repeated duty-cycle changes.

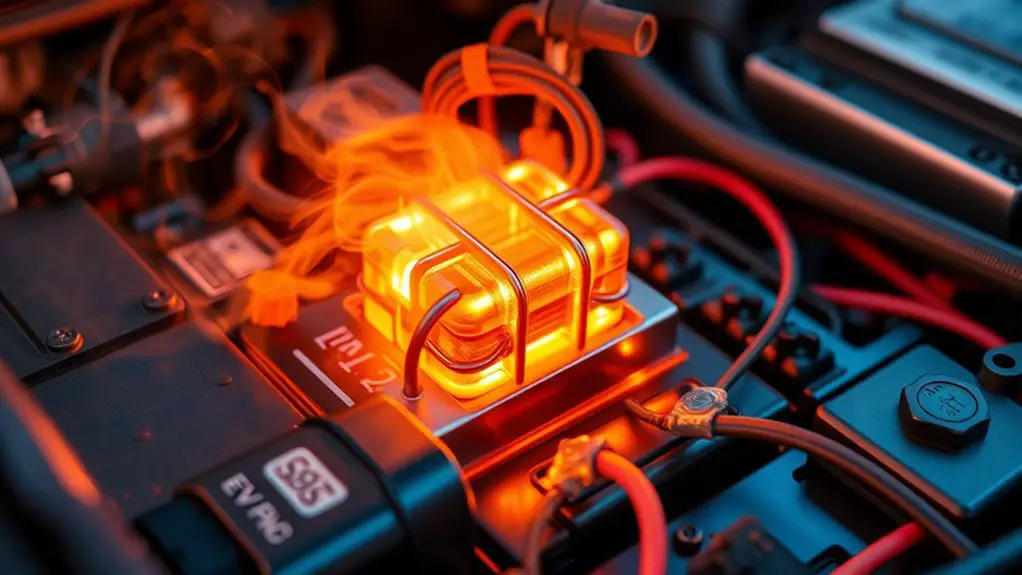

How Heat Impacts Power Delivery and Battery Efficiency

Heat adds resistance losses that directly affect power delivery and can waste energy as heat rather than usable output. You’ll see battery efficiency drop when these losses climb, especially under rapid charging or high-load conditions. Effective thermal management is essential to minimize these impacts and maintain consistent performance.

Heat and Power Loss

In EV systems, excessive heat from the pre-charge resistor reduces charging efficiency and drains available power that would otherwise reach the traction battery. You’ll see how heat translates to real losses through material limits and electrical paths, not just temperature numbers. The key ideas are thermal resistance and power dissipation, which govern how much energy leaks as heat rather than useful charging.

- Thermal resistance dictates how easily heat moves from the resistor to the surroundings, shaping temperature rise under load.

- Power dissipation defines the portion of input energy converted to heat, reducing net charging current to the battery.

- Thermal management efficiency directly affects voltage drop, charger responsiveness, and sustained performance during EV mode.

Keep monitoring junction temps, guarantee adequate cooling, and design for margin without compromising system freedom.

Battery Efficiency Impact

Battery efficiency matters because the heat generated by the pre-charge resistor directly competes with energy delivered to the traction battery. When heat rises, your system must work harder to maintain the same voltage, reducing the effective energy reaching the cell stack. You’ll see lower battery performance as a consequence of parasitic losses, which limits usable capacity and peak power. The efficiency of energy conversion declines when thermal losses climb, especially during high-demand EV mode shifts. In practice, this means more heat sits in the resistor and wiring, stealing a portion of the input from the battery. By isolating and reducing that heat, you preserve energy for propulsion, improving range consistency and reducing state-of-health impact over time.

Thermal Management Needs

Efficient thermal management is essential because excess heat from the pre-charge path directly degrades power delivery and overall battery efficiency. You’ll optimize performance by addressing heat sources, pathways, and removal strategies with measurable targets and repeatable checks.

- thermal insulation: minimize heat transfer from hot components toward sensitive circuits, reducing stray warming of the battery pack.

- heat dissipation: design for effective air, liquid, or phase-change cooling that keeps temperatures within safe margins during peak load.

- monitoring and control: implement real-time temperature sensing and adaptive duty cycling to sustain steady power delivery without overheating.

Assessing Heat Thresholds and Protective Limits

You’ll establish clear heat threshold criteria to determine when pre-charge resistor operation remains safe. Monitoring should map protective limit thresholds to observable signals and actionable responses, ensuring margins stay within design specs. Start with defining, measuring, and validating these signals so you can promptly adjust control logic if thresholds are approached or breached.

Heat Threshold Criteria

To assess heat threshold criteria, you first define the operating temperature window and the maximum allowable temperatures for the pre-charge resistor under EV mode. You then establish measurable limits that reflect safe operation, minimal degradation, and predictable response during transients. This framework guides validation of heat dissipation and thermal conductivity pathways, ensuring reliable performance under load changes.

- Define the allowable temperature range for continuous operation and for short-duration peaks.

- Specify acceptable delta-T limits between ambient, device surface, and core junction during EV mode.

- Document how thermal resistance and cooling effectiveness translate into real-world margins under varying environmental conditions.

Protective Limit Thresholds

Protective Limit Thresholds set the guardrails for heat performance beyond basic operating ranges. You assess protective limits by defining acceptable thermal exposure over time, not just peak temps. Start with a baseline: identify maximum continuous operating temperatures and short-term spikes your system can tolerate without degradation. Then translate those limits into actionable thresholds for the control logic, ensuring conservative margins to compensate for aging, ambient variation, and load surges. You’ll map thermal thresholds to specific actions—reductions in duty cycle, delayed charging, or safe shutdown—so you preserve power availability while avoiding damage. Document clear criteria for entering and exiting protective states, and validate them under representative duty cycles. The aim is predictable behavior, measured risk, and freedom to operate within safe, defined boundaries.

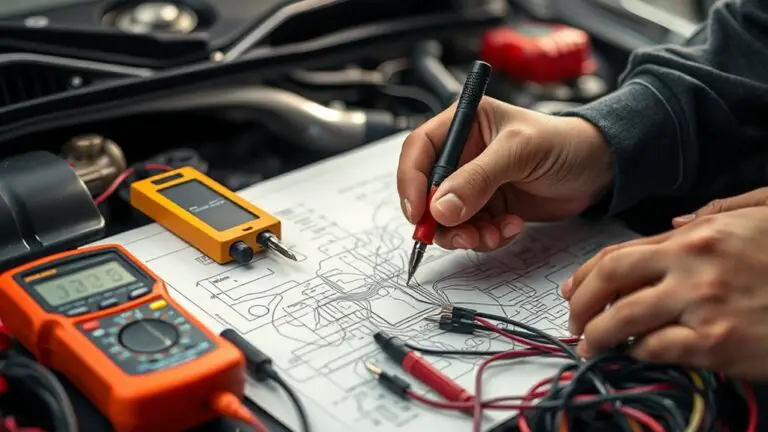

Thermal Monitoring Signals

Thermal monitoring signals translate heat data into actionable control by continuously comparing real-time temperatures, rates of change, and exposure duration against predefined limits. You’ll evaluate thresholds via thermal sensors and guarantee signal calibration aligns sensor output with actual conditions. The goal is a precise feedback loop that prevents overheating while preserving power delivery in EV mode.

- Establish baseline readings from thermal sensors and verify accuracy through regular signal calibration, accounting for ambient variation.

- Map temperature trajectories to protective actions, documenting acceptable rates of change and time limits before interrupts or throttling occur.

- Implement redundant sensing and cross-checks to confirm faultless decision-making under dynamic load and cooling conditions.

Practical Solutions: Cooling, Duty Cycling, and Sizing

Effective cooling, duty cycling, and proper sizing are practical levers you can use to manage pre-charge resistor heat in EV mode. You approach cooling with targeted strategies that remove heat where it matters most: high-conductivity paths, tight joints, and ventilated enclosures. Implement cooling strategies that balance airflow, surface area, and thermal interfaces, prioritizing consistent contact between the resistor and its heat sink. For duty cycling, you orchestrate load profiles so the resistor experiences intermittent use rather than continuous stress, sustaining performance without overtaxing components. Size components to match transient currents, ensuring the resistor’s rating remains above peak demand and that parasitic losses stay within limits. Documenting a repeatable design method helps you predict thermal margins under varying ambient conditions. You’ll value simplicity that scales: modular cooling adds, predictable duty cycles, and verifiable sizing checks. In practice, these principles yield reliable EV mode operation, reduced performance dips, and clearer design responsibility.

Monitoring and Maintenance for Consistent EV Performance

Regular monitoring and proactive maintenance are essential to keep EV mode heat management reliable, especially as operating conditions change. You’ll want a disciplined approach that emphasizes early detection and steady performance. By tracking temperature trends and component responses, you preserve power delivery and minimize unexpected drops in EV mode.

Regular monitoring and proactive maintenance keep EV mode heat management reliable, adapting to changing conditions and sustaining steady performance.

1) Implement a routine for thermal sensors data review, focusing on outliers, drift, and sensor fault codes, and align thresholds with manufacturer specs.

2) Establish periodic performance tracking benchmarks, logging thermal margins during varied loads, ambient temps, and duty cycles to reveal creeping degradation.

3) Schedule proactive maintenance tasks that clean, reseal, or replace cooling paths, verify electrical connections, and validate controller firmware aligned with cooling strategies.

This method keeps you in control, ensuring consistent EV performance while you enjoy the freedom to push your vehicle within safe, documented limits.

Frequently Asked Questions

Can Pre-Charge Resistor Heat Cause Audible Swishes or Noises?

Yes, pre-charge heat can create audible pre charge sounds and thermal noise. You’ll hear faint clicks, rattles, or swooshes as components expand, contacts shift, or insulation flexes with temperature changes. You may notice it only when the system heats or cools, and during certain loads. To verify, listen for consistency, check for loose fittings, and monitor temps. If noises persist, consult the service manual and address thermal management, wiring, or resistor mounting.

Do Temperature Spikes Affect EV Range Estimates During Cold Starts?

Yes, temperature spikes can affect your EV range estimates during a cold start. You’ll see a temperature impact as battery chemistry slows and you use more auxiliary power, which trims range until the pack warms. Track how cold starts shift energy demand, and allow for conservative estimates in forecasts. Stay precise: monitor pack temperature, drive cycle, and thermal system readiness. This approach empowers you to manage expectations and preserve freedom in your planning.

How Quickly Do Resistors Recover After Thermal Shutdown Events?

Ever wonder how quickly resistors recover after thermal shutdown events? They typically regain function once temperatures drop below a safe threshold, but exact timing depends on heat dissipation and ambient conditions. You should expect a recovery window from a few seconds to several minutes. Focus on thermal management to speed it up: improve airflow, heat sinking, and control duty cycles. Resistor recovery hinges on effective thermal management and precise, methodical monitoring of temps.

Are There Industry Standards for Maximum Pre-Charge Resistor Temperatures?

The answer is yes: there are industry standards limiting maximum temperature for pre-charge resistors. You’ll find targets tied to reliability margins and material constraints, with compliance often demanded by automotive and energy sectors. You should design for safe operation within those limits to guarantee industry compliance, including margins for ambient conditions and airflow. You must monitor, document, and validate temperatures during testing, occupational safety, and long-term duty cycles, maintaining clear records for audits and certification.

Can Vibration Impact Thermal Contact Efficiency in Pre-Charge Circuits?

Vibration can affect thermal contact efficiency in pre-charge circuits. You’ll see altered contact pressure and micro-movements that disrupt thermal paths, reducing thermal conductivity and creating hot spots. To mitigate, secure connections, inspect fasteners, and use vibration-damping materials. Regularly verify contact resistance and mounting integrity. By monitoring vibration effects, you preserve stable thermal transfer, prevent performance loss, and maintain reliable pre-charge behavior in dynamic environments. Keep the assembly tight and lab-tested for long-term durability.