When to Upgrade to an Inverter for Better Reliability

You should upgrade to an inverter when your baseline plus peak load consistently exceeds current capacity and you experience frequent outages or voltage sags that threaten critical equipment. Quantify by tracking continuous load, startup surges, and essential versus nonessential draws, then size for a 20–30% reserve margin. Prioritize critical loads (servers, HVAC, medical devices) with a tiered backup strategy. If issues cluster during storms, a diversified, higher-reliability inverter makes sense; more details await.

Assessing Your Power Reliability Needs

Evaluating your power reliability needs starts with a clear inventory of load and risk. You’ll map baseline power demand, peak demand, and critical circuits to quantify exposure to outages. Gather measurements: continuous load, intermittent spikes, startup surges, and essential timings. Calculate a reliability index by comparing mean time between outages to expected uptime, and translate that into required reserve capacity. Evaluate energy efficiency opportunities that reduce demand variability, such as high-efficiency appliances, lighting controls, and load shedding strategies, since lower power demand lowers needed backup capacity. Identify acceptable outage duration per circuit and the alerting window you’ll tolerate before restoration, then classify devices into critical, important, and nonessential tiers. Consider environmental constraints, installation footprint, and available budget to define a target system rating. Use this framework to justify inverter sizing, battery energy storage, and protection requirements, ensuring you maintain operational freedom without compromising safety or performance.

Recognizing Frequent Outages and Brownouts

Frequent outages and brownouts are the practical reality behind sizing a reliable inverter system. You’ll quantify risk by documenting outage patterns across the last 12 months, noting duration, time of day, and frequency per week. Translate each event into a usable metric: average outage span, daily exposure hours, and the percentage of hours below critical voltage. Compare brownout frequency to your critical loads’ thresholds, identifying caps where voltage sags become unacceptable. Build a simple risk matrix: severity (voltage drop, restart need), likelihood (historical cadence), and impact (load interruption, data loss). If outages cluster during peak demand or storms, plan for higher reserve capacity or a short-term energy buffer. Don’t confuse nuisance interruptions with reliability gaps; distinguish swells in transient events from sustained outages. Your goal is to establish a clear minimum inverter runtime and a scalable margin for future demand, based on precise outage pattern profiling. This clarity drives informed, freedom-preserving upgrade decisions.

Evaluating Load Types and Sensitivity

When evaluating your loads, start by categorizing each device by type, criticality, and sensitivity to voltage sags and interruptions; this means listing essential loads (servers, HVAC controls, refrigeration, medical devices) separately from nonessential ones (entertainment, charging).

Sensitive equipment and proper load categorization drive inverter sizing and UPS decisions. Identify peak currents, inrush, and duration of interruptions you must tolerate. Quantify each category’s contribution to total draw and fault risk, then map to acceptable voltage drop thresholds. Use this two-tier approach to determine whether a single inverter can sustain essential loads during outages or if a diversified solution is required.

| Essential Loads | Nonessential Loads |

|---|---|

| servers, HVAC, medical devices | entertainment, chargers |

This structure clarifies prioritization, guides protection schemes, and supports reliability goals without overengineering.

Balancing Cost, Savings, and Return on Investment

Balancing cost, savings, and return on investment means translating the load categorization you established into a disciplined financial framework. You’ll map marginal costs against expected resilience gains, distinguishing capital expenditure from operating savings and risk mitigation. Conduct a rigorous cost analysis that includes inverter hardware, installation, controls, and ancillary support, then juxtapose it with projected energy savings, demand charges, and avoided outages. Use conservative load growth assumptions to avoid overstating benefits and to keep the plan credible under uncertain conditions. Construct an investment timeline that aligns upfront cash outlays with multi-year payback, incorporating discounting for risk and a clear break-even point. Sensitivity testing should reveal how changes in energy prices, incentives, or maintenance costs shift the ROI envelope. Communicate the financial case succinctly to stakeholders, highlighting payback horizon, net present value, and internal rate of return. Your objective is a transparent, actionable, cost-driven justification for uptake.

Choosing Size, Type, and Backup Strategy

You’ll start by matching load心 profiles to inverter capacity, prioritizing a practical reserve margin (commonly 20–30% of peak or 1.25–1.5× the critical-load draw) to maintain reliability during fluctuations while avoiding oversizing. You’ll then select inverter types aligned with your load mix: pure sine for inductive motors, high-frequency for electronics, or hybrid for mixed profiles. Use sizing guidelines that separate essential and nonessential circuits, and cap peak draw with a deliberate headroom target, typically 1.5× the largest critical-load event. For backup strategy, define a tiered topology: uninterruptible essential loads, then a shift for noncritical circuits, and an optional cold-start run during prolonged outages. Decide between grid-tied, off-grid, or hybrid configurations based on availability and autonomy goals. Confirm efficiency targets at planned loads and evaluate runtime estimates, ensuring storage and charging rates satisfy the worst-case duration. This yields reliable autonomy with scalable, clear pathways for expansion.

Frequently Asked Questions

How Does Inverter Reliability Compare Across Brands and Models?

Inverter reliability varies by brand comparison and model performance, but generally you’ll see top brands delivering MTBFs around 5–15 years and 99% uptime in real-world tests. The strongest models show consistent efficiency, thermal management, and fault isolation. Compare vendor warranties, failure rates, and service networks. Track continuous operation hours, conversion efficiency, and surge handling. You’ll favor brand comparison data from independent labs, and model performance dashboards, to pick a solution that matches your reliability goals with sustainable, long-term support.

Do Inverters Handle Renewable Energy Sources Like Solar or Wind?

Sure. Yes, inverters handle solar and wind inputs, provided they’re matched to input voltage, power rating, and knowledge of source dynamics. You’ll want solar compatibility and wind integration specs that support MPPT, surge, and frequency-accurate output. In practice, choose inverters with appropriate DC-AC conversion efficiency, dynamic response, and ISNOW feedback safeguards. If you design for 0.8–1.0 p.u. grid interaction, you’ll achieve reliable, scalable renewable integration while preserving system autonomy and control.

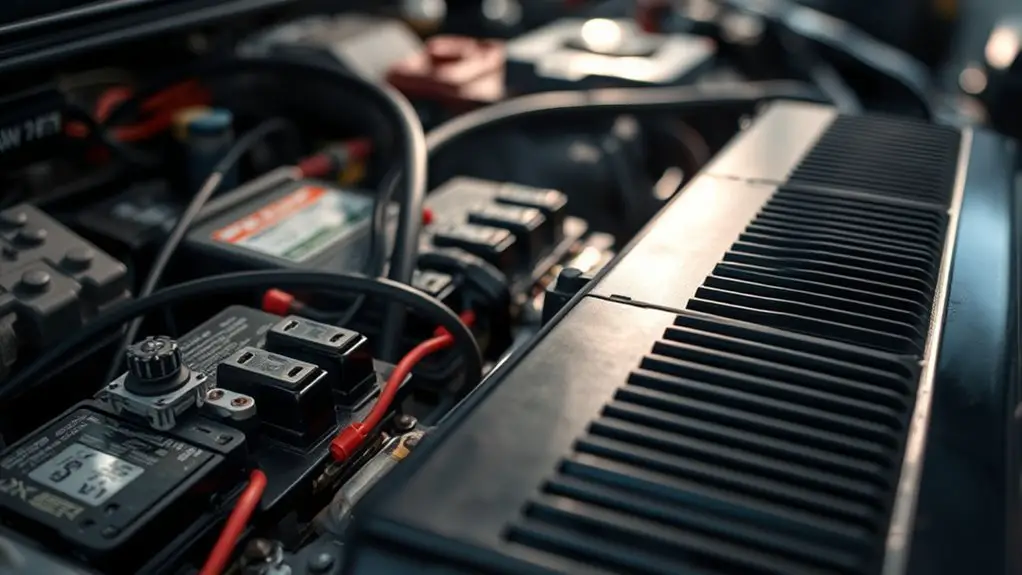

What Maintenance Is Required for Long-Term Inverter Performance?

You should conduct regular checks: battery maintenance every 6–12 months, verify electrolyte levels if applicable, and monitor state-of-charge to avoid deep discharges. Inspect cooling fans and vents, tighten terminals, and replace worn connectors. Perform inverter cleaning monthly to remove dust buildup, especially from heat sinks. Track temperatures and voltages with a calibrated meter, logging results for trend analysis. Schedule proactive replacements before derating, and keep a maintenance log for long-term reliability.

Can an Inverter Improve Power Quality for Sensitive Equipment?

To your question: yes, an inverter can improve power quality for sensitive equipment, especially if you choose a unit with clean sine wave output, low THD, and tight regulation under load. You’ll see reduced voltage sag, flicker, and transient spikes. Confirm specifications meet your device tolerances, install proper grounding, and verify crest factor and EMI filtering. In practical terms, quantify improvements via measurements before/after, and document it for future reliability decisions. You’ll gain measurable, actionable control.

Are There Hidden Costs Beyond Initial Purchase Price?

Yes, there are hidden costs beyond the initial price. You’ll face installation expenses for proper sizing, wiring, and certification, plus potential operational costs from efficiency losses, maintenance, and periodic battery replacement. Factor in cooling, inverter standby power, and warranty terms. You’ll want a total cost of ownership forecast: upfront plus ongoing electricity draw, service intervals, and accessory upgrades. This approach keeps your system reliable, predictable, and aligned with your freedom to plan long-term.